Continuous parallel traction method and traction device

A traction device and traction plate technology, applied in textiles, textiles, papermaking, looms, etc., can solve the problems of inconsistent tension control of adjacent fabrics, cumbersome process, improve production efficiency and fabric quality performance, and simplify the process. , the effect of rapid and continuous traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

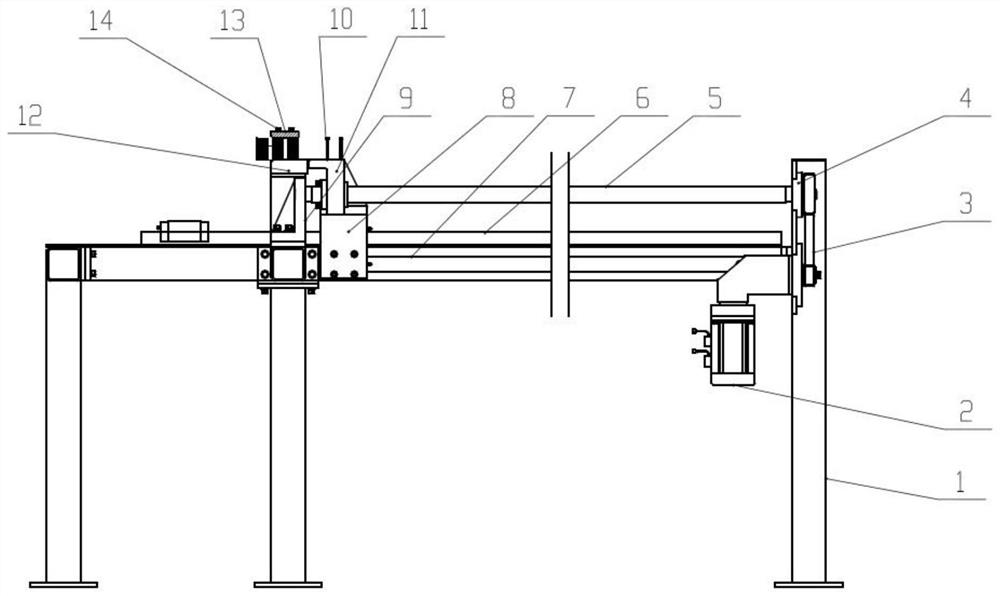

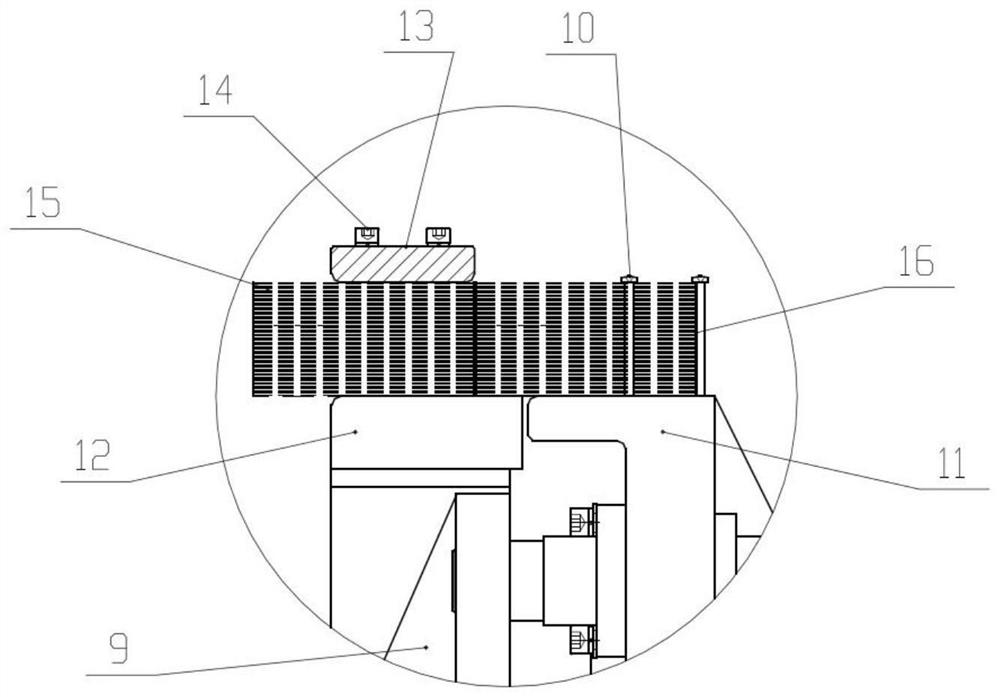

[0056] Such as Figure 1-3 As shown, a continuous parallel traction device, the device includes the following parts:

[0057] Drive mechanism: including servo motor 2 with reducer, transmission mechanism 3, screw rod 5 with flange, screw seat I4, screw seat II9; servo motor 2, screw seat I4, screw seat II7 through the inner hexagon The screws and nuts are installed on the frame 1; the two ends of the screw rod 5 are installed on the screw seat I4 and the screw seat II7; the transmission mechanism 3 is installed on the output shaft of the servo motor 2; the transmission mechanism 3 Installed on one end of the screw rod 5;

[0058] Guide mechanism: including linear slide rail I6 with slider, linear slide rail II7 with slider, and slider connecting corner piece 8; the linear slide rail I6 with slider and linear slide rail II7 with slider respectively use their The mounting surfaces of the sliders are installed on the frame 1 in a manner perpendicular to each other; the connecting...

Embodiment 2

[0073] Such as Figure 4 As shown, a continuous parallel traction device, the device includes the following parts

[0074] Traction guide mechanism: including sprocket 18 and chain plate 17;

[0075] Drive mechanism: used to drive the sprocket 18 to rotate;

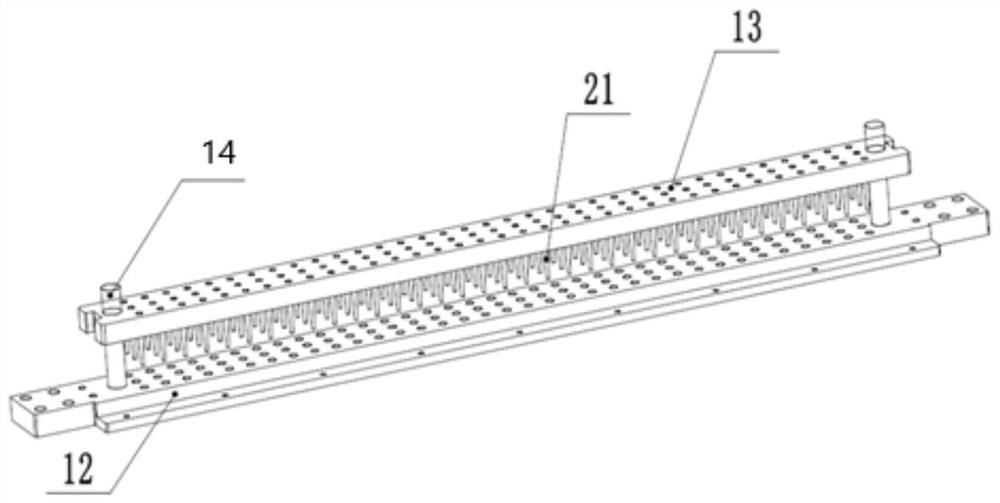

[0076] Yarn tie mechanism: including detachable screws arranged on the chain plate 17;

[0077] Traction fixing mechanism: including the traction upper splint with acupuncture 21 and fixing bolts, the chain plate 17 is provided with holes corresponding to the acupuncture.

[0078] It also includes the control system and the installation mechanism of the traction upper splint;

[0079] The control system detects the length of the woven fabric, and according to the length of the woven fabric, controls the traction upper splint installation mechanism to install the traction upper splint, and clamps the reserved section of fabric.

[0080] A method for continuous traction using the above-mentioned traction device, compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com