Passivation solution for improving cementing performance of zinc-aluminum-magnesium plated steel and preparation method of passivation solution

A passivation solution, zinc-aluminum-magnesium technology, applied in the field of passivation solution, can solve the problems of bonding failure, insufficient coating adhesion, toxic and environmental protection, etc., achieve good adhesion points, improve bonding performance, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

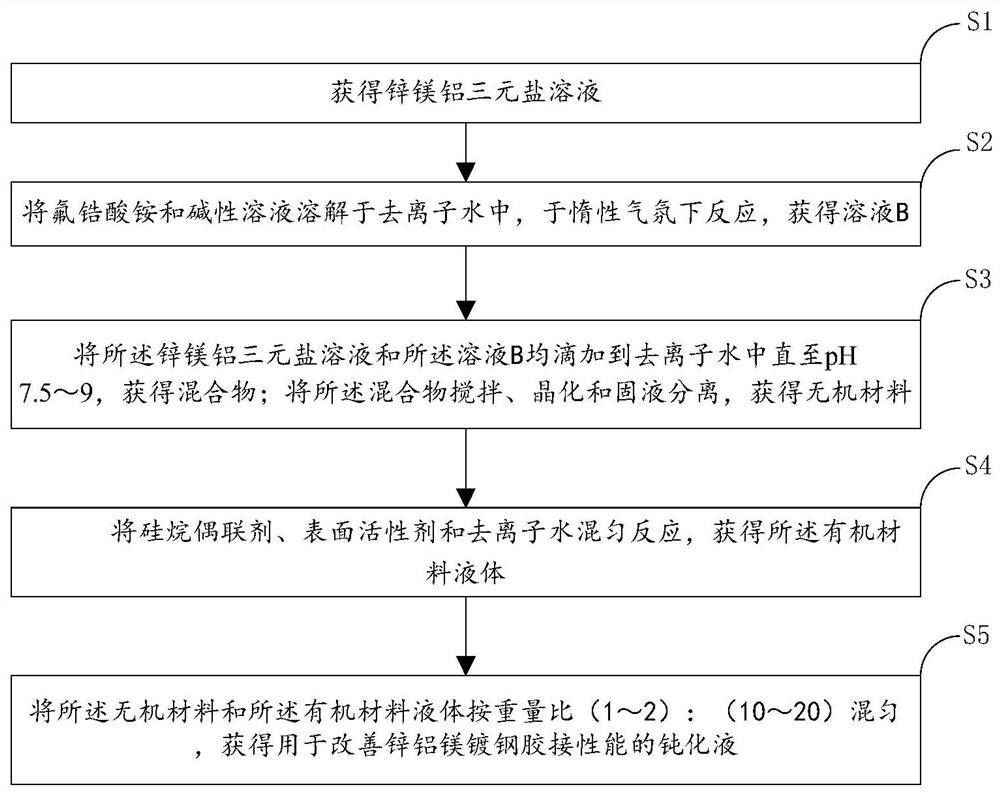

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of a passivation solution provided by the embodiment of the present invention has the following advantages:

[0038] (1) The inorganic material prepared in the embodiment of the present invention——fluorozirconate ion intercalated magnesium-zinc-aluminum ternary hydrotalcite, the interlayer anion fluozirconate ion has the ability to exchange, when the magnesium element on the surface of the alloy generates magnesium carbonate When the corrosion product is loose and porous, the fluozirconate ion will replace the carbonate, and the fluozirconate ion will combine with the magnesium ion to form a stable chelation product, which protects the surface of the coating and reduces the generation of loose and porous products. When combined with the adhesive When in contact, the mechanical properties of stretching and peeling are greatly improved, thereby improving the bonding performance of zinc-aluminum-magnesium-plated steel.

[0039] (2) Inorganic material...

Embodiment 1

[0062] This embodiment provides a passivation solution for improving the bonding performance of zinc-aluminum-magnesium-plated steel and a preparation method thereof. The specific operations are as follows:

[0063] 1. Preparation of inorganic materials:

[0064] 5 parts of Zn(NO 3 ) 2 ·6H 2 O, 5 parts of Mg(NO 3 ) 2 ·6H 2 O and 5 parts Al(NO 3 ) 3 9H 2 O was dissolved in 50 parts of deionized water to form a homogeneous solution (referred to as solution A) at room temperature under an inert atmosphere.

[0065] At room temperature under an inert atmosphere, 3 parts of NaOH and 5 parts of H 8 f 6 N 2 Zr was dissolved in 50 parts of deionized water to make solution B (deionized water was boiled to remove dissolved carbon dioxide and kept at 25°C for use).

[0066] The solution A and the solution B were simultaneously added dropwise into a beaker containing 100 parts of deionized water until the pH of the final mixture was adjusted to 8.

[0067] The resulting mixtu...

Embodiment 2

[0073] This embodiment provides a passivation solution for improving the bonding performance of zinc-aluminum-magnesium-plated steel and a preparation method thereof. The specific operations are as follows:

[0074] (1) Preparation of inorganic materials:

[0075] 5 parts of Zn(NO 3 ) 2 ·6H 2 O, 5 parts of Mg(NO 3 ) 2 ·6H 2 O and 5 parts Al(NO 3 ) 3 9H 2 O was dissolved in 00 parts deionized water to form a homogeneous solution (referred to as solution A) at room temperature under an inert atmosphere.

[0076] At room temperature under an inert atmosphere, 5 parts of NaOH and 10 parts of H 8 f 6 N 2 Zr was dissolved in 100 parts of deionized water to make solution B (deionized water was boiled to remove dissolved carbon dioxide and kept at 30°C for use).

[0077] The solution A and the B were simultaneously added dropwise into a beaker containing 150 parts of deionized water until the pH of the final mixture was adjusted to 9. The resulting mixture was stirred (at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap