Nitride semiconductor light emitting device and method of manufacturing the same

A technology for nitride semiconductors and light-emitting devices, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor adhesion and decreased bonding reliability, and achieve improved adhesion characteristics, long-term reliability, and improved optical properties. Effects of Scattering Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

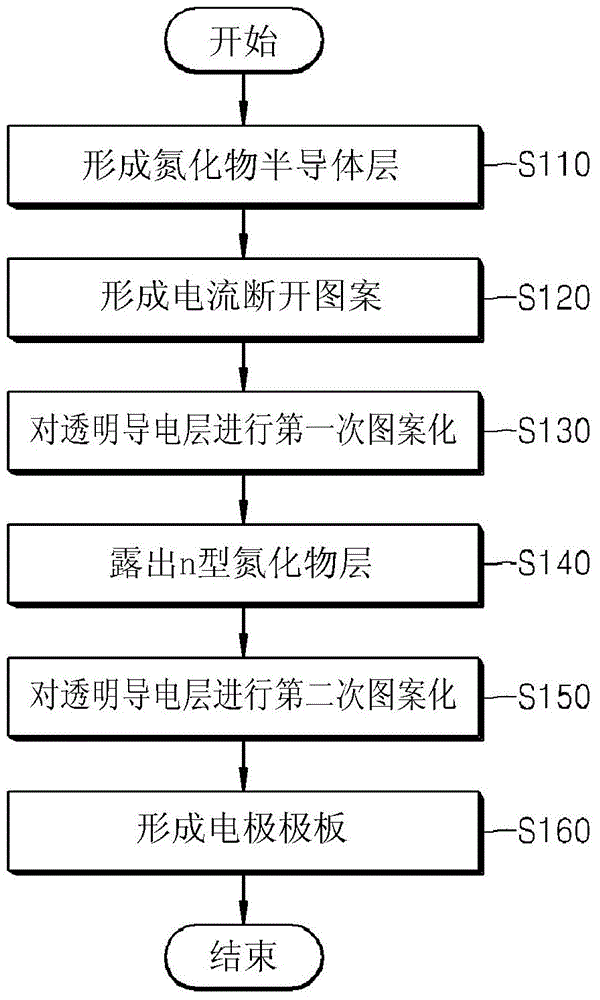

[0027] Hereinafter, referring to the accompanying drawings, a nitride semiconductor light emitting device and a manufacturing method thereof according to preferred embodiments of the present invention will be described in detail as follows.

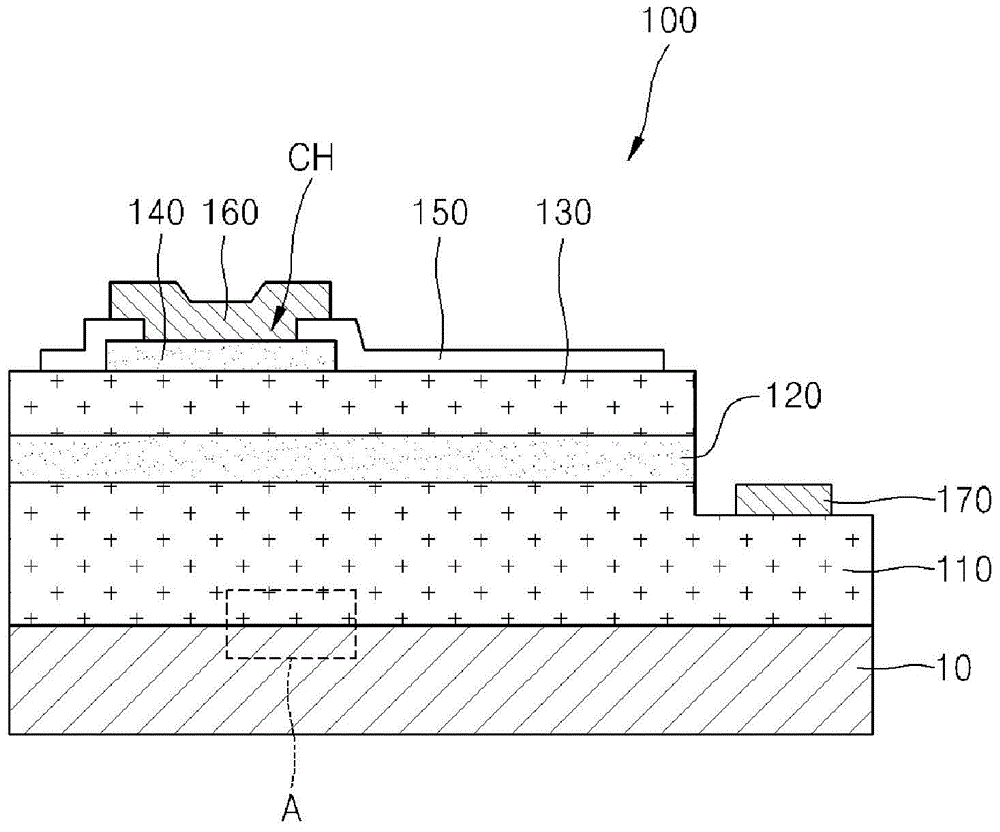

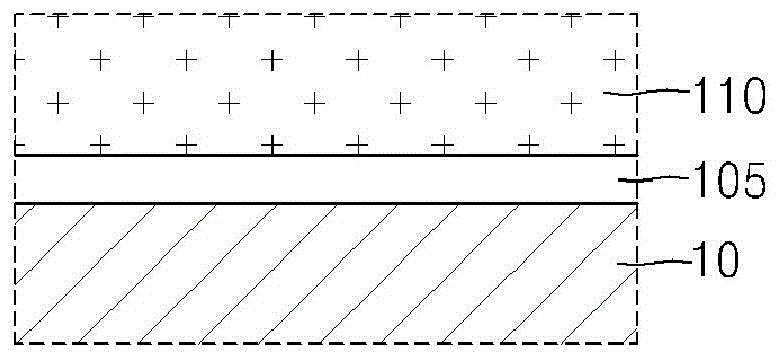

[0028] figure 1 is a sectional view showing a nitride semiconductor light emitting device according to an embodiment of the present invention, figure 2 for figure 1 A magnified view of part A of .

[0029] refer to figure 1 and figure 2 , the nitride semiconductor light emitting device 100 shown in the embodiment of the present invention includes: n-type nitride layer 110, active layer 120, p-type nitride layer 130, current disconnection pattern 140, transparent conductive pattern 150, p-electrode plate 160 and n-electrode plate 170 . Also, the nitride semiconductor light emitting device 100 of the embodiment of the present invention may further include a buffer layer 105 .

[0030] The n-type nitride layer 110 is formed on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com