Printed wiring board and method of producing the same

A circuit board and conductor circuit technology, which is applied in the fields of printed circuit manufacturing, printed circuit, multi-layer circuit manufacturing, etc., can solve the problem of poor bonding performance between conductor circuit and solder barrier layer, smaller contact area, conductor circuit and solder barrier In order to reduce resin residues, improve metal bonding characteristics, and prevent the reduction of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0193]Preparation of adhesive layer for electroless plating

[0194] (1) 35 parts by weight of the acrylated product of 25wt% cresol novolak type epoxy resin with a molecular weight of 2500 manufactured by Nippon Kayaku Corporation and 3.15 parts by weight of Aronics M315 manufactured by Toa Gosei Corporation The photosensitive monomer, 0.5 parts by weight of S-65 defoamer manufactured by Sannopuco and 3.6 parts by weight of N-methylpyrrolidone (NMP) were mixed with stirring.

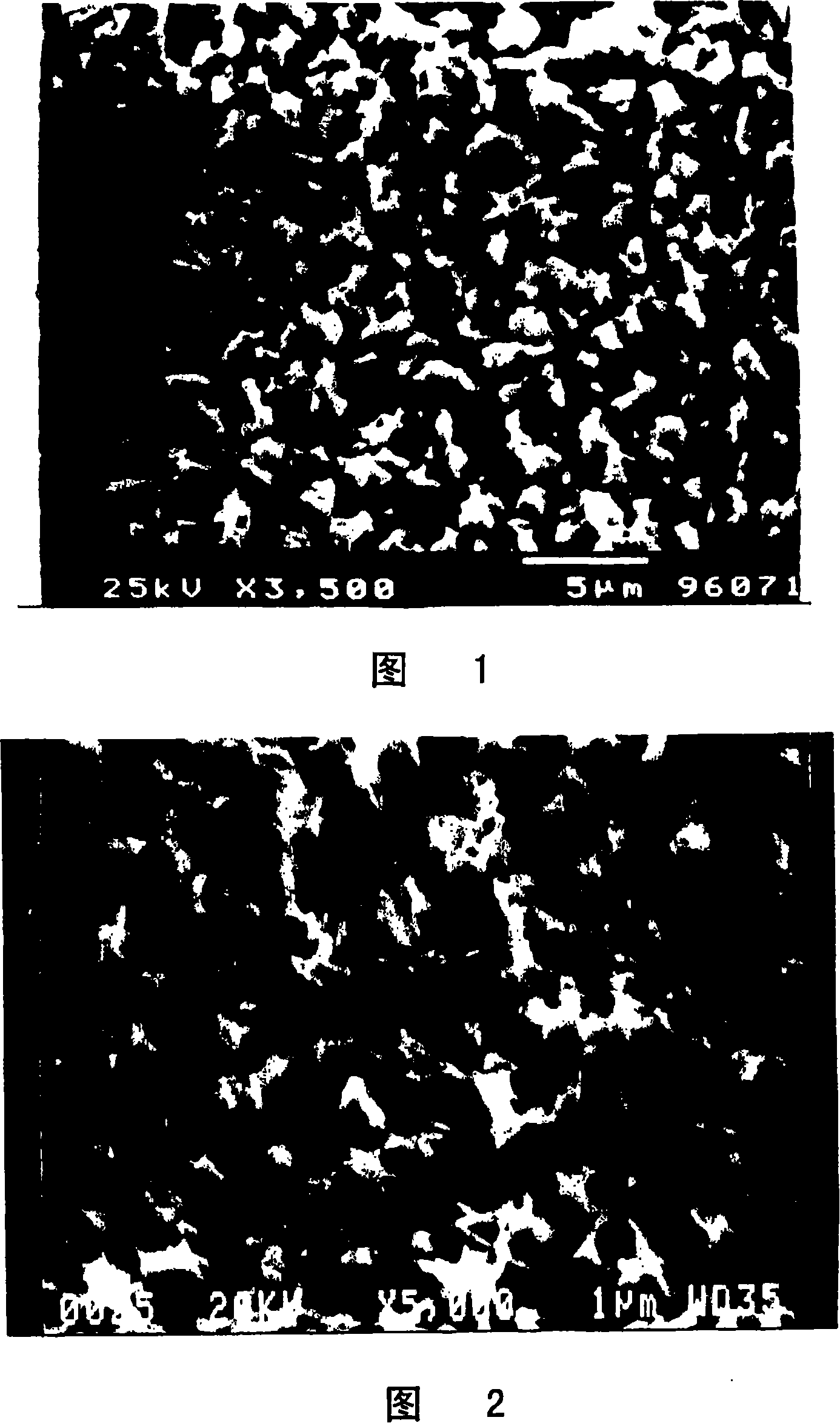

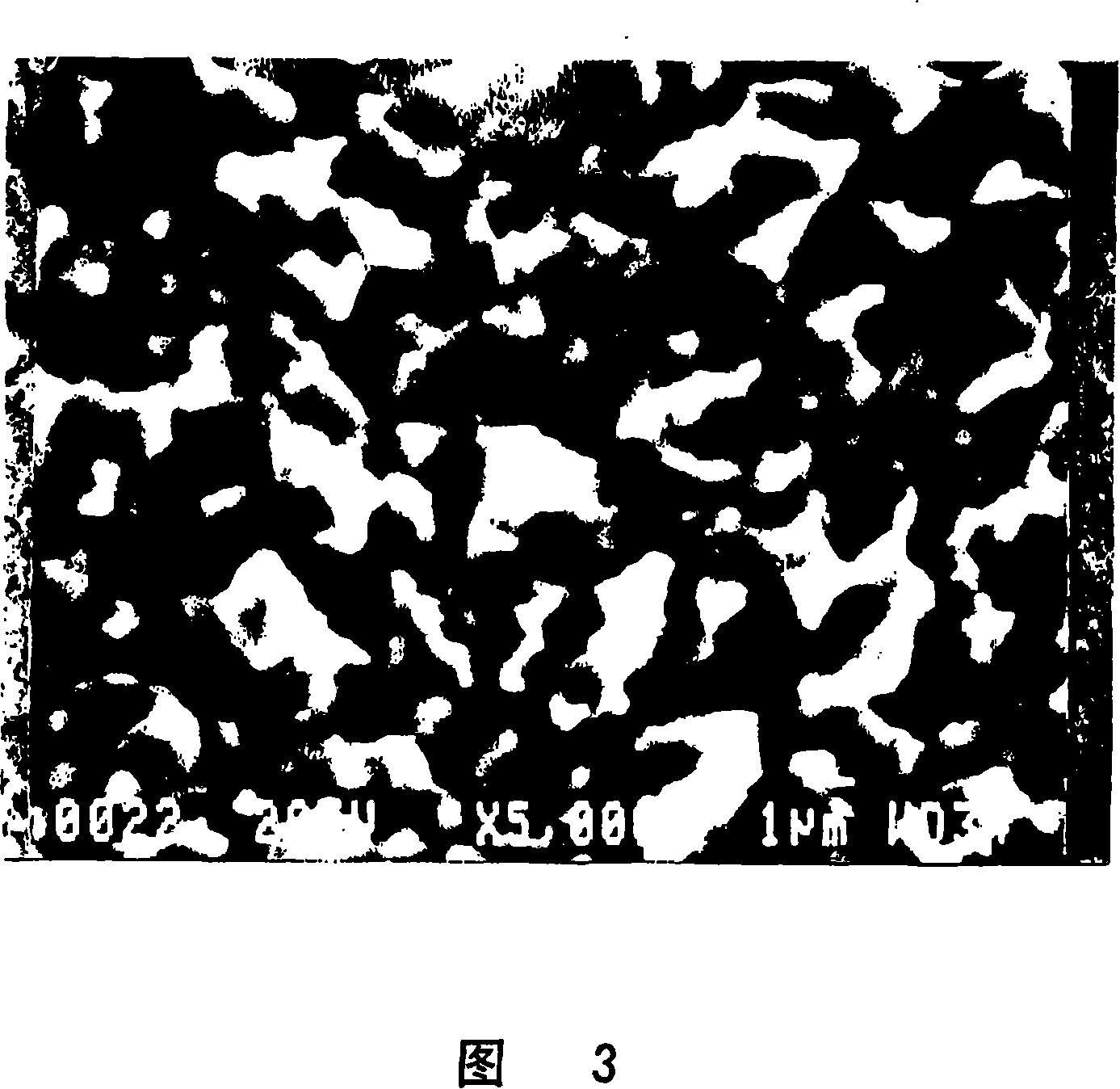

[0195] (2) 12 parts by weight of polyethersulfone (PES) and 7.2 parts by weight of the epoxy resin particles manufactured by Sanyo Kasei under the trade name Polymerpol with an average particle size of 0.1 μm and 3.09 parts by weight whose average particle size is 0.5μm of the same epoxy resin, particles are mixed and 30 parts by weight of NMP are added and mixed with a ball mill under stirring.

[0196] (3) 2 parts by weight of an imidazole curing agent manufactured by Shikoku Kasei under the trade name 2...

example 2

[0244] According to the steps (1) and (2) in Example 1, the core board 31 with the roughened surface of the conductor circuit shown in FIG. 21 was prepared. On the other hand, the single-sided circuit board 15 shown in FIGS. 13-17 is prepared.

[0245] The specific preparation of the single-sided circuit board 15 is as follows. 12μm thick copper foil 6 is placed on the glass epoxy substrate 5 to form a single-sided copper-clad board 7, as shown in Figure 13. The surface of the copper-clad board 7 not covered with copper foil 6 is exposed to CO 2 Under the gas laser beam, an opening 8 with a diameter of 50 μm is formed, as shown in FIG. 14.

[0246] After that, under the conditions listed in step (11) of Example 1, the copper-clad plate 7 was electroplated to form a plating film 9 as shown in FIG. 15. After that, a stainless printing mask with an opening of 1.0 μm in diameter corresponding to the position of the through hole is placed, and Au-Pd conductive paste manufactured by Tan...

example 3

[0250] Repeat the manufacturing process steps of Example 1, except that the roughened surface of the lower conductor circuit is not replaced with tin, and the metal layer is made of other non-oxidizing metals, or no metal layer is formed. The heating test and thermal cycle test were performed on the finished circuit board in the same manner as in Example 1. The results are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com