Processing equipment for antibacterial clothing fabric

A technology for processing equipment and fabrics, applied in textile processing machine accessories, textile material processing, continuous processing of textile materials, etc., can solve problems such as affecting production efficiency, affecting the uniformity of antibacterial liquid, and appearing wrinkles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below:

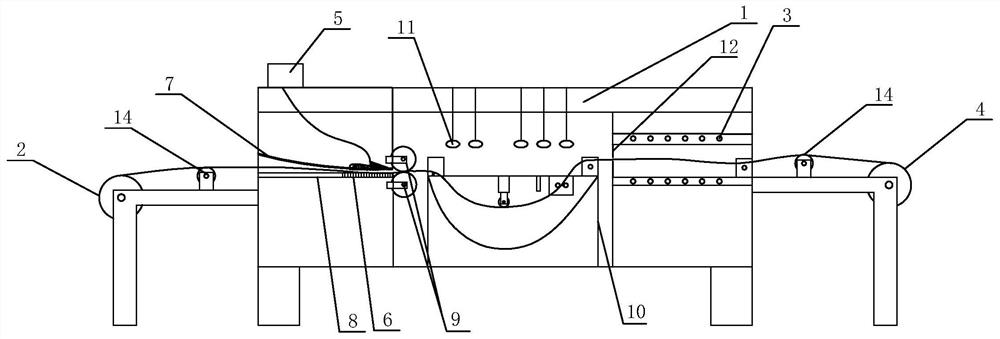

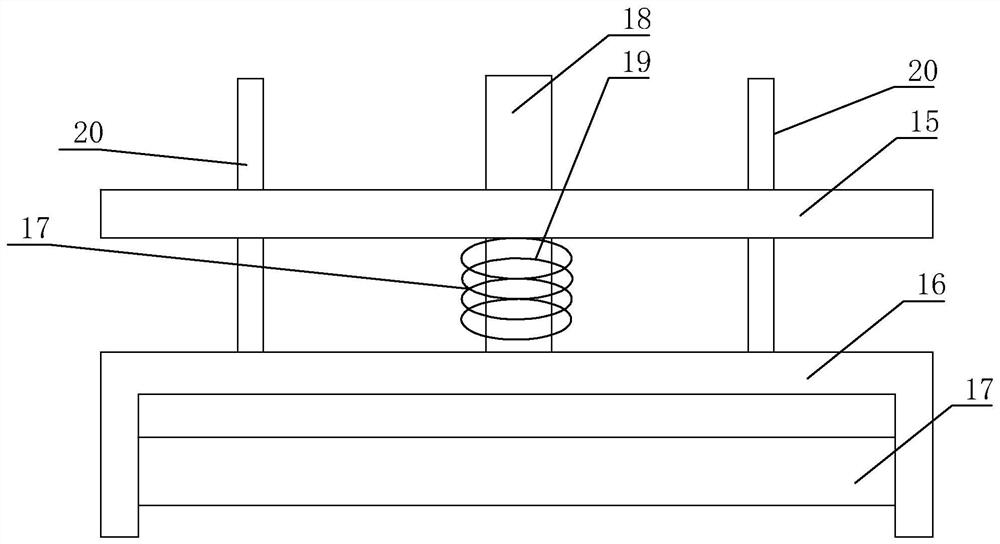

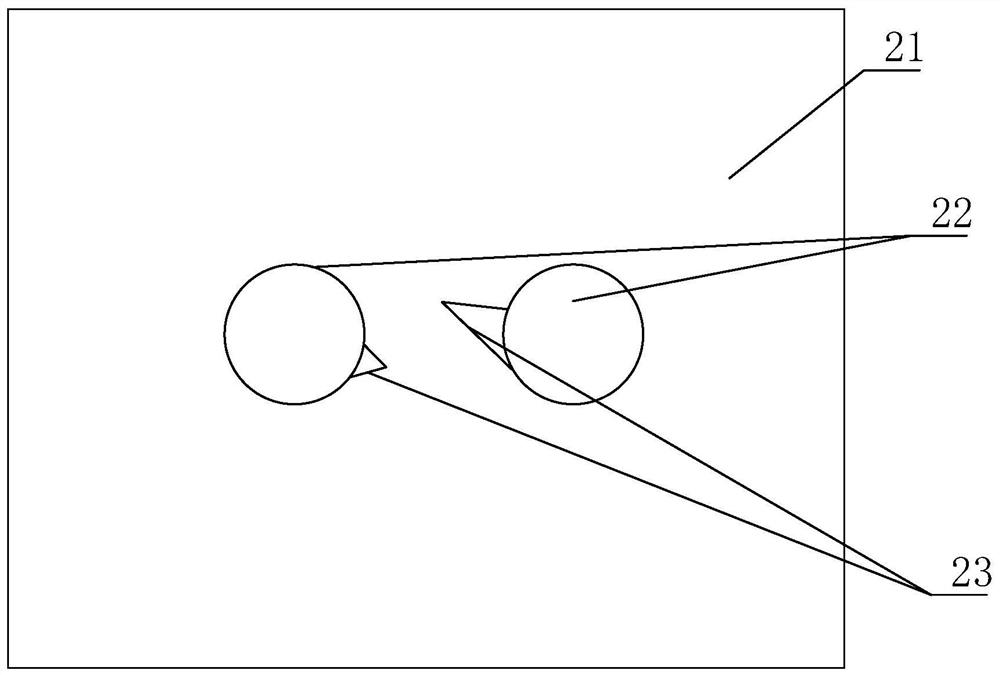

[0024] See for details Figure 1 to Figure 4 :

[0025] An antibacterial clothing fabric processing equipment, which includes a frame 1, and the frame 1 is provided with a feeding roller 2, a blowing and stretching device, a spraying device, a drying device 3 and a winding roller in sequence from left to right. 4. The flat blowing and stretching device includes an air pump 5, an air pipe, a support assembly 6, an upper deflector 7 and a lower deflector 8. The lower deflector 8 is horizontally fixed on the frame 1, and the upper deflector 7 is obliquely arranged on the bottom. Above the deflector 8, both sides of the upper deflector 7 and the lower deflector 8 are fixedly connected to the frame 1, and a material passage for the cloth to pass through is formed between the upper deflector 7 and the lower deflector 8 , a blow hole 13 is provided on the upper deflector 7, the blow hole 13 is connected with an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com