Flue gas purification system used in continuous smelting process

A technology of flue gas purification system and smelting process, which is applied in the field of flue gas purification system, and can solve problems such as environmental thermal pollution, high flue gas temperature, and reduced flue gas purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

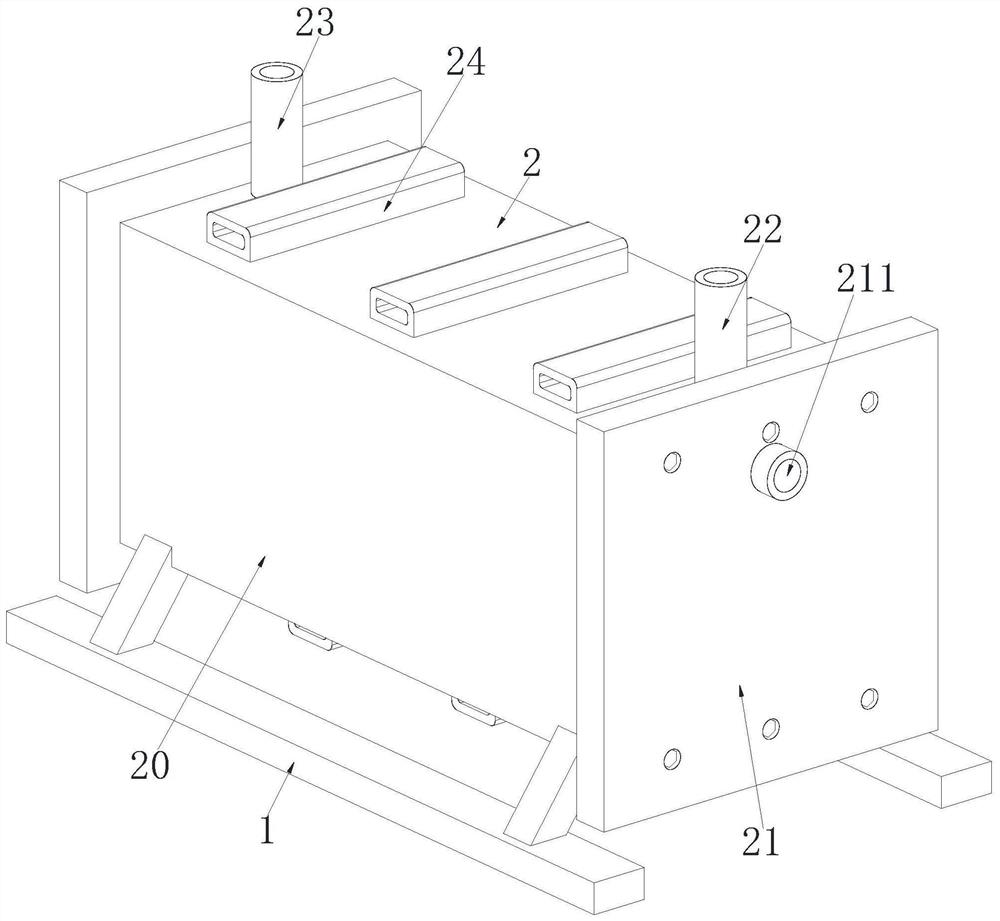

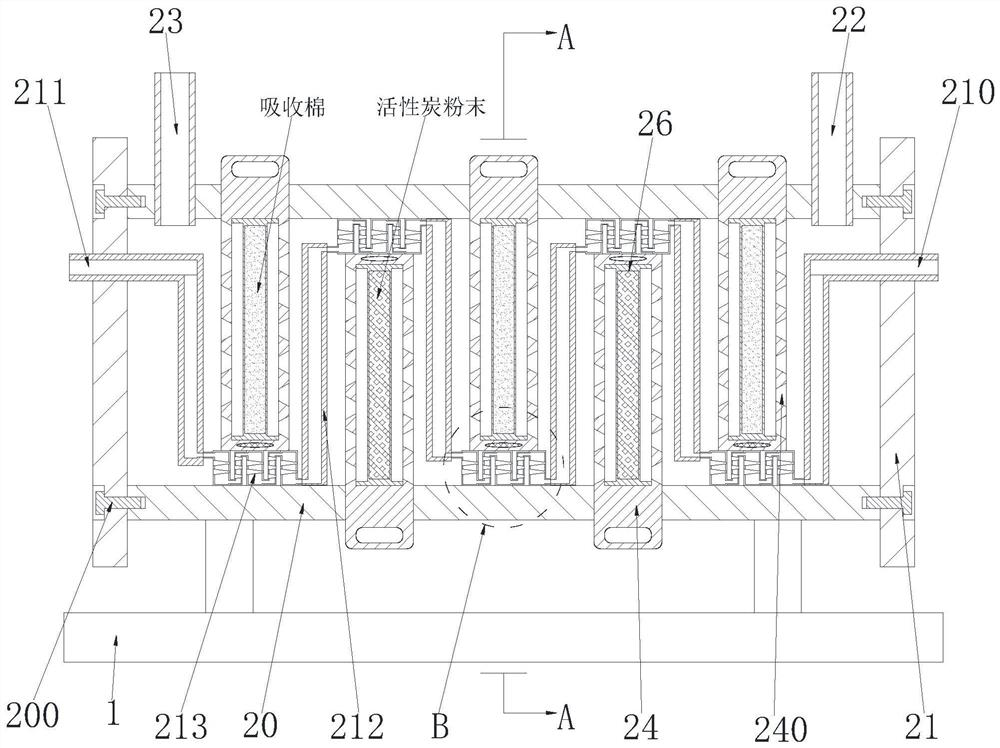

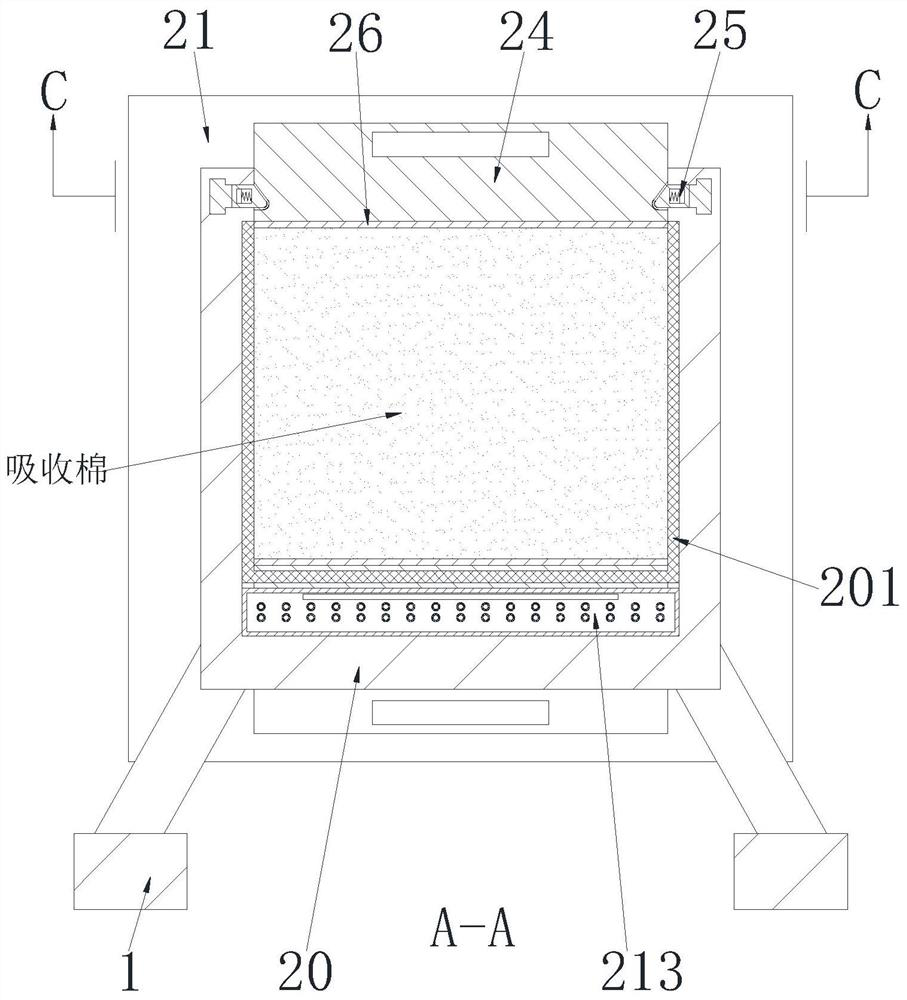

[0031] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0032] A flue gas purification system used in a continuous smelting process, comprising a support base 1 and a purification unit 2, two support bases 1 are arranged symmetrically, and a purification unit 2 is provided between the upper ends of the two support bases 1; wherein:

[0033] The purification unit 2 includes a purification pipeline 20, a purification sealing plate 21, an air inlet pipe 22, an air outlet pipe 23, a mounting frame 24, a limit branch chain 25 and an absorption plate 26, and a purification pipeline is arranged between the upper ends of the two support bases 1 20. The cross-section of the purification pipeline 20 is a square structure, the two ends of the purification pipeline 20 are symmetrically installed with purification se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap