A Positioning Method for Measuring Points of Tunnel Section

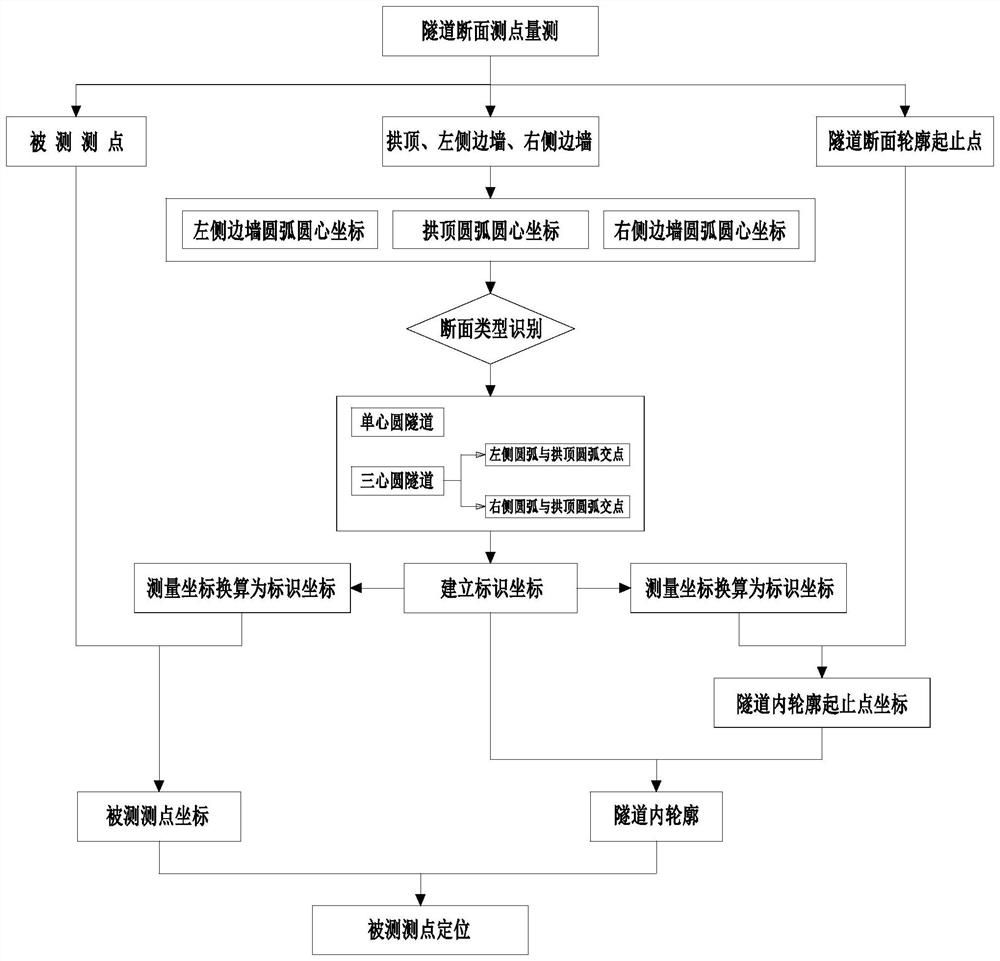

A positioning method and point-measuring technology, which is applied in the directions of section drawing, measuring device, surveying and navigation, etc., can solve the problems of heavy workload, high risk of working environment, large error, etc., so as to simplify the workload, improve the detection speed and The effect of increasing the level of intelligence, improving accuracy and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

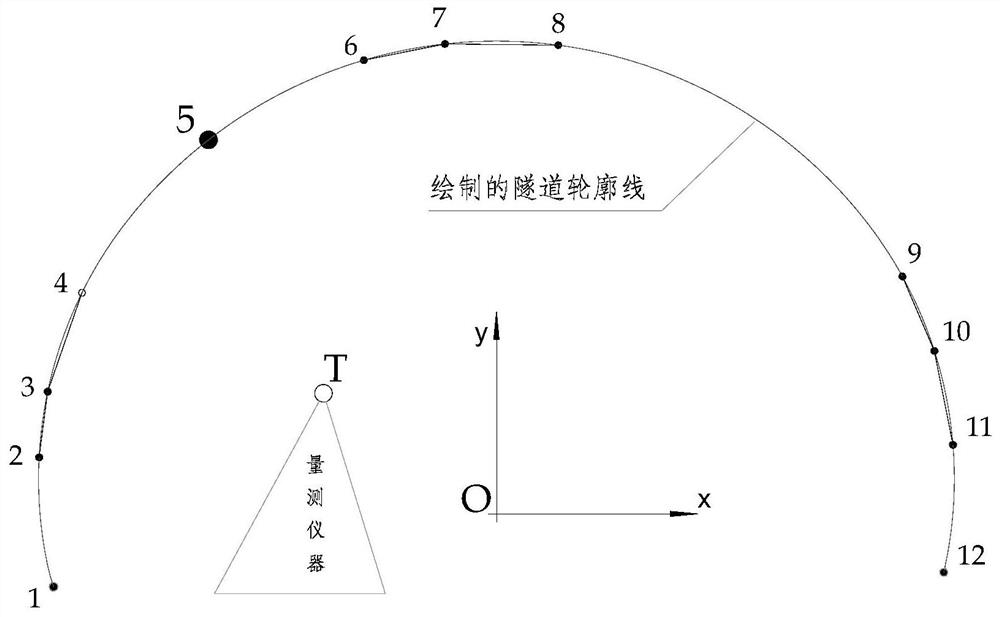

[0109] Example 1: Measurement of a single-hole, two-lane tunnel with a design speed of 80km / h, in which three marked points are measured at the arch, and the coordinates are: (51.98, 426.15), (69.91, 431.12), (84.29, 434.68 ); measure 3 marker points on the left side wall, the coordinates are: (-369.85, -30.68), (-372.93, -46.51), (-374.94, -58.26); measure 3 markers on the right side wall point, the coordinates are: (807.35, 1.25), (811.42, -16.34) and (815.08, -33.01); the measurement coordinates of the starting and ending points of the tunnel inner contour are: (-375.4, -247.59) and (822.74, -229.09 ); the coordinates of the measured point to be calibrated are: (X tx , X ty )=(-147.8, 324.18), the coordinates of the measured point to be calibrated are the data measured by the instrument according to the existing benchmark.

[0110] (1) Confirm whether the measuring points of the vault and the left and right side walls meet the requirement that the distance between the mea...

Embodiment 2

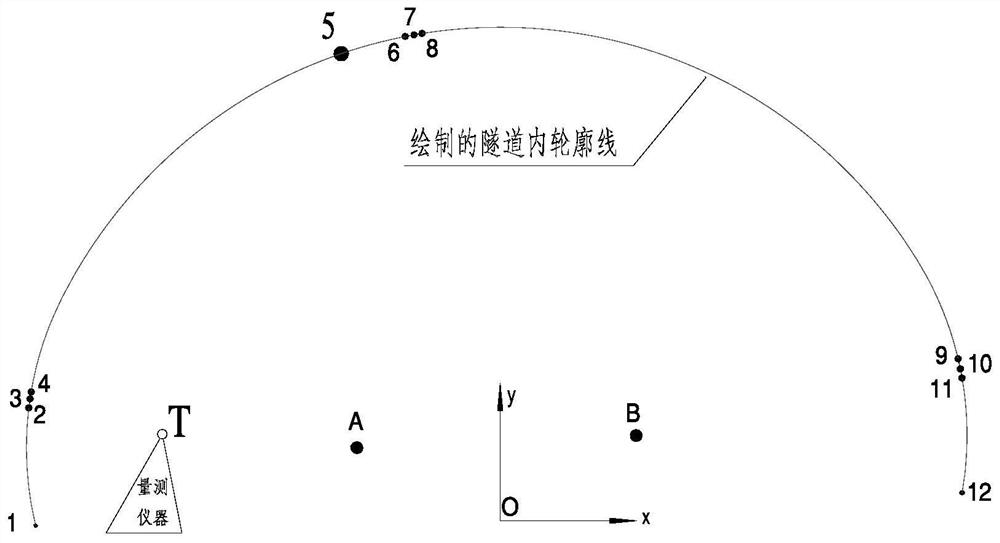

[0139] Embodiment 2: A certain three-lane section is measured, wherein three points are measured at the arch, and the coordinates are respectively: (469.79, 765.3), (486.86, 768.51) and (502.29, 771.13), and the left side wall is measured at 3 points, the coordinates are: (-258.11, 50.7), (-255.78, 68.02) and (-253.68, 81.19), the right side wall measures 3 points, the coordinates are: (1539.34, 144.99), (1542.25 , 125.29) and (1546.97, 107.99), the measurement coordinates of the starting and ending points of the tunnel inner contour are: (-244.9, -176.31), (1547.07, -112.88); the coordinates of the measured points to be calibrated are: (X tx , X ty ) = (346.07, 732.11).

[0140] (1) Confirm whether the measuring points of the vault and the left and right side walls meet the requirement that the distance between the measuring points is 10cm to 20cm;

[0141] The adjacent spacing of the three measuring points at the vault position is: 17.4cm, 15.7cm; the adjacent spacing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com