Testing device for applying bidirectional compression load

A test device and compressive load technology, applied in the direction of applying stable tension/compression to test material strength, measuring devices, testing of mechanical components, etc., can solve problems that have not been reported and have not been carried out in two-way compression loading tests of structural parts , to achieve the effect of reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

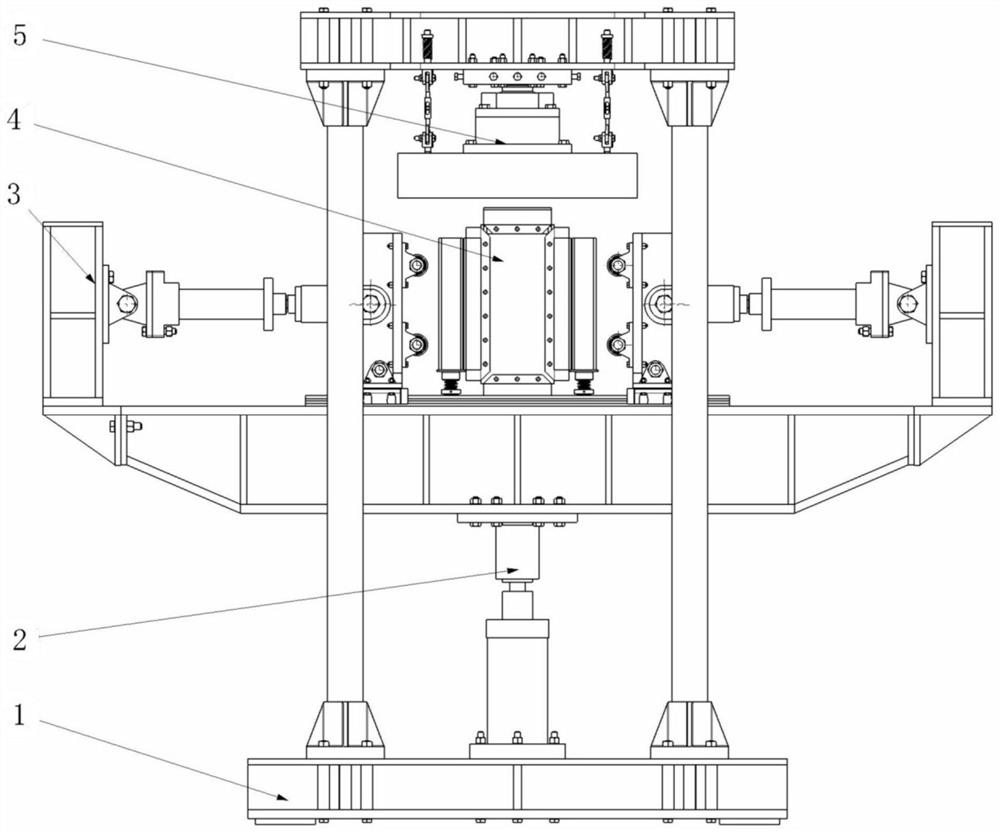

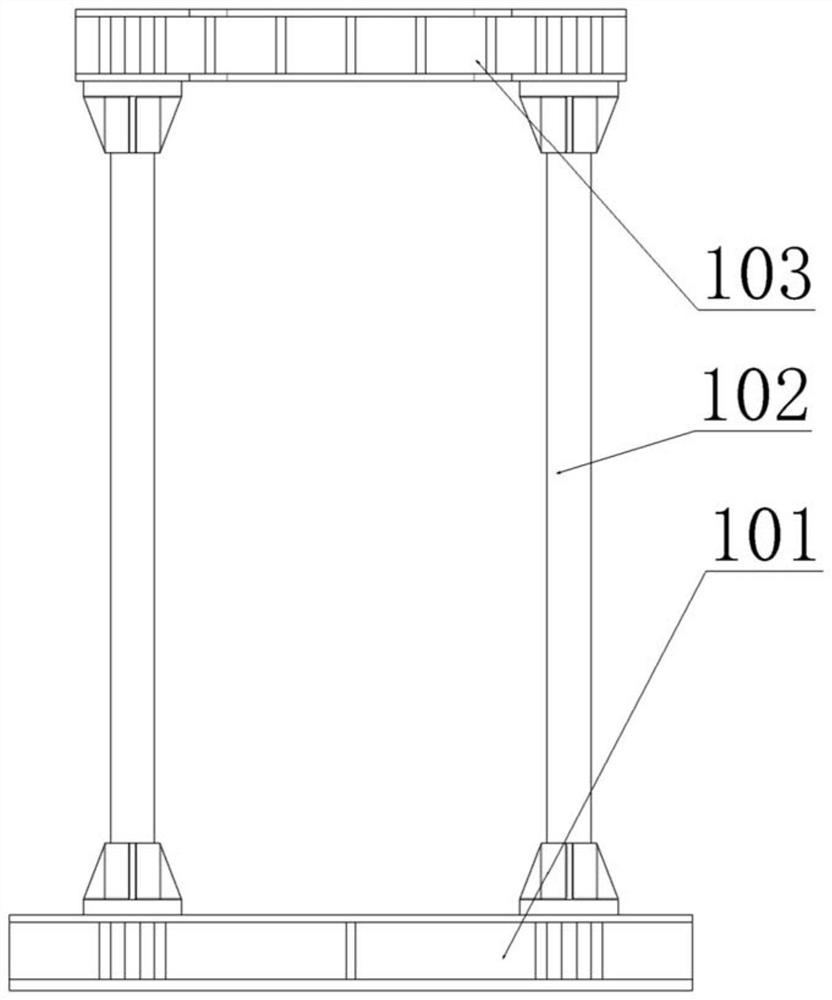

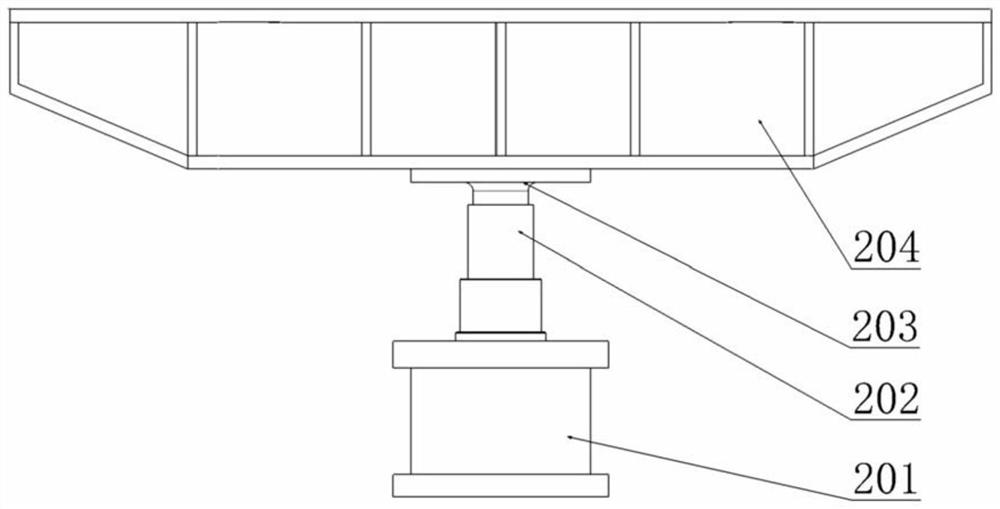

[0028] see Figure 1 to Figure 6 , the present invention provides a test device for applying bidirectional compressive load, comprising: test device frame 1, axial compression and force measuring assembly 2, lateral compression assembly 3, test piece assembly 4 and upper platform and leveling assembly 5, wherein :

[0029] The test device frame 1 provides installation positions for the axial compression and force measurement component 2 and the upper platform and leveling component 5, and the three form a self-balancing device; the axial compression and force measurement component 2 and the transverse compression component 3 are respectively installed on the test In the two directions of the component assembly 4, bidirectional compressive loads are provided; the upper platform and the leveling assembly 5 are installed on the top of the test piece component 4 and the top of the test device frame 1, and are used as an adjustable upper compression platform; during the test , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com