Cutting-resistant and puncture-resistant industrial protective glove

An industrial protection and puncture-resistant technology, applied in the field of weaving, can solve the problems of expensive strong fiber composite materials, protective gloves only have cut resistance, and cannot resist puncture by sharp objects, etc., and achieve good cut resistance and puncture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Cut and puncture resistance of industrial protective gloves

[0047] The present invention measures cut performance according to the ANSI / ISEA 105 cut protection standard and measures puncture resistance according to the ASTM F2878 standard. In one embodiment, the weight ratio of water-based polyurethane and silica sol in the mixed adhesive layer of water-based polyurethane and silica sol is 1-3:3-1, different weight ratios can prepare gloves with different cutting resistance and puncture resistance , and the test results are shown in Table 1.

[0048] Table 1 - Effect of weight ratio of waterborne polyurethane to silica sol on cut resistance and puncture resistance

[0049]

[0050]It can be seen from the results in Table 1 that when the coated fabric only uses the polyurethane layer, the industrial protective gloves have a cut resistance of 7N to 8N according to ANSI / ISEA105, and when the coated fabric only uses the silica sol layer, the industrial protective gl...

Embodiment 2

[0055] Puncture Resistance of Gloves Coated Fabrics with Different Coating Numbers

[0056] The industrial protective gloves of the present invention can be made of at least one layer of cut-resistant and puncture-resistant coated fabric. Preferably, the industrial protective gloves of the present invention may comprise one-layer, two-layer or three-layer coated fabrics, and the results of the puncture resistance test are shown in the table below.

[0057] Table 2 - Puncture resistance of one- and three-layer coated fabrics

[0058]

[0059] It can be seen from the results in Table 2 that when the industrial protective glove comprises a layer of coated fabric, the industrial protective glove has a puncture resistance of 3N to 4N according to ASTM F2878, and the puncture resistance grade is grade 1. When the industrial protective glove comprises a three-layer coated fabric, the industrial protective glove has a puncture resistance of 11 N according to ASTM F2878 with a pu...

Embodiment 3

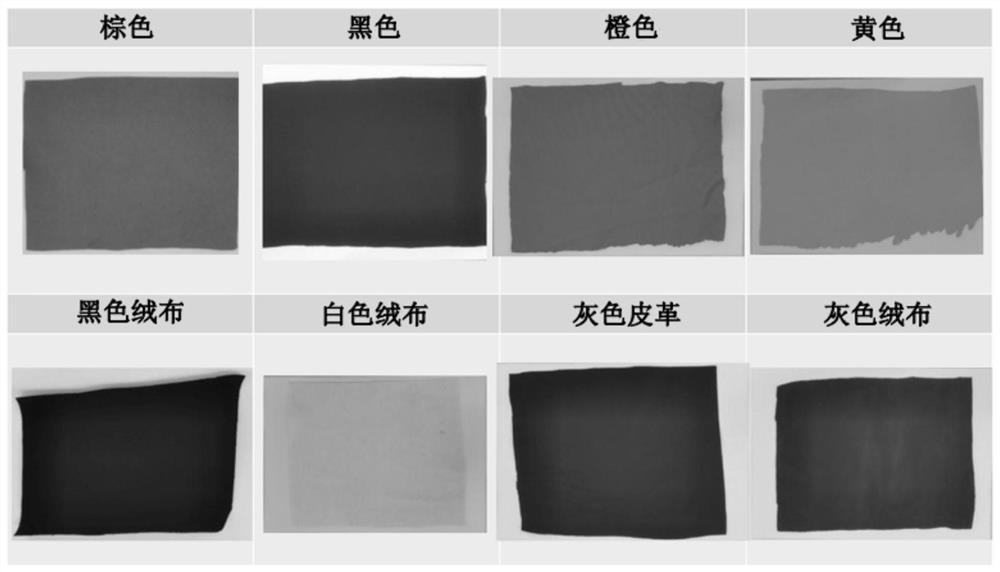

[0061] figure 1 Different types of coated fabrics are shown and the areal densities of these coated fabrics are given in the table below. As can be seen from the results in Table 3, Samples 1 to 4 are layered fabrics of different colors, having a thickness of approximately 150 to 250 g / m 2 while samples 6 to 9 are coated fabrics of different types (flannel or leather) in black, white or gray, with approximately 150 to 350 g / m 2 area density.

[0062] Table 3 - Area density of different types of coated fabrics

[0063]

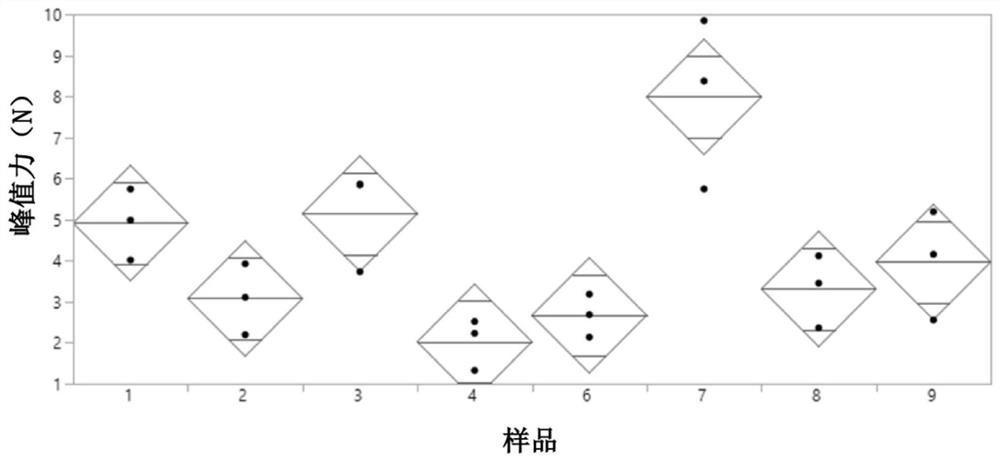

[0064] figure 2 Shown is the puncture resistance of different types of coated fabrics. Samples 1 to 4 are layered fabrics of different colors with a puncture resistance of 1N to 7N according to ASTM F2878, while samples 6 to 9 are coated fabrics of different types (velvet or leather) in black, white or gray according to ASTM F2878 F2878 has a puncture resistance of 2N to 10N.

[0065] definition

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com