A kind of janus structure polymer-based nano metal catalyst and its preparation method and application

A technology of structural polymers and nano-metals, applied in catalyst activation/preparation, organic compound preparation, organic compound/hydride/coordination complex catalysts, etc. It can solve the chemical composition partition and precise control technology of microstructure needs to be further Improve and other problems, to achieve good emulsification effect, avoid loss, shorten the effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

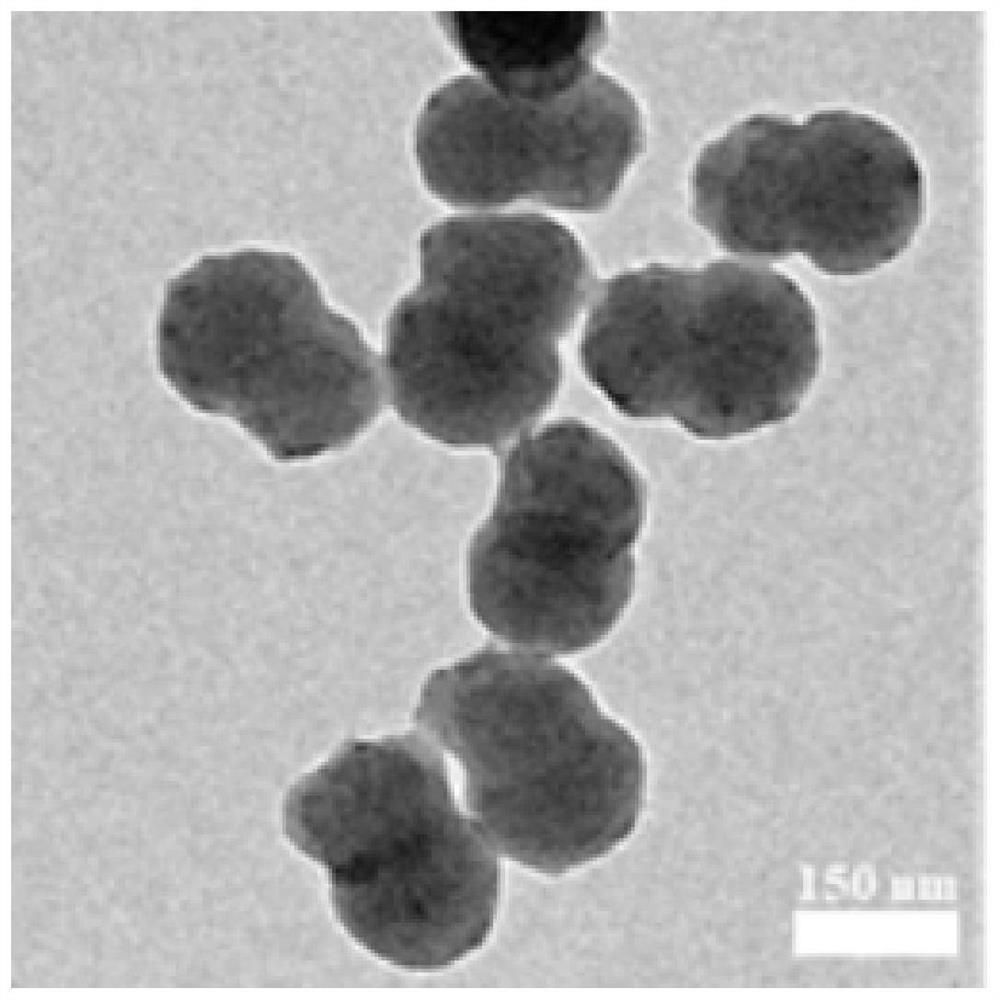

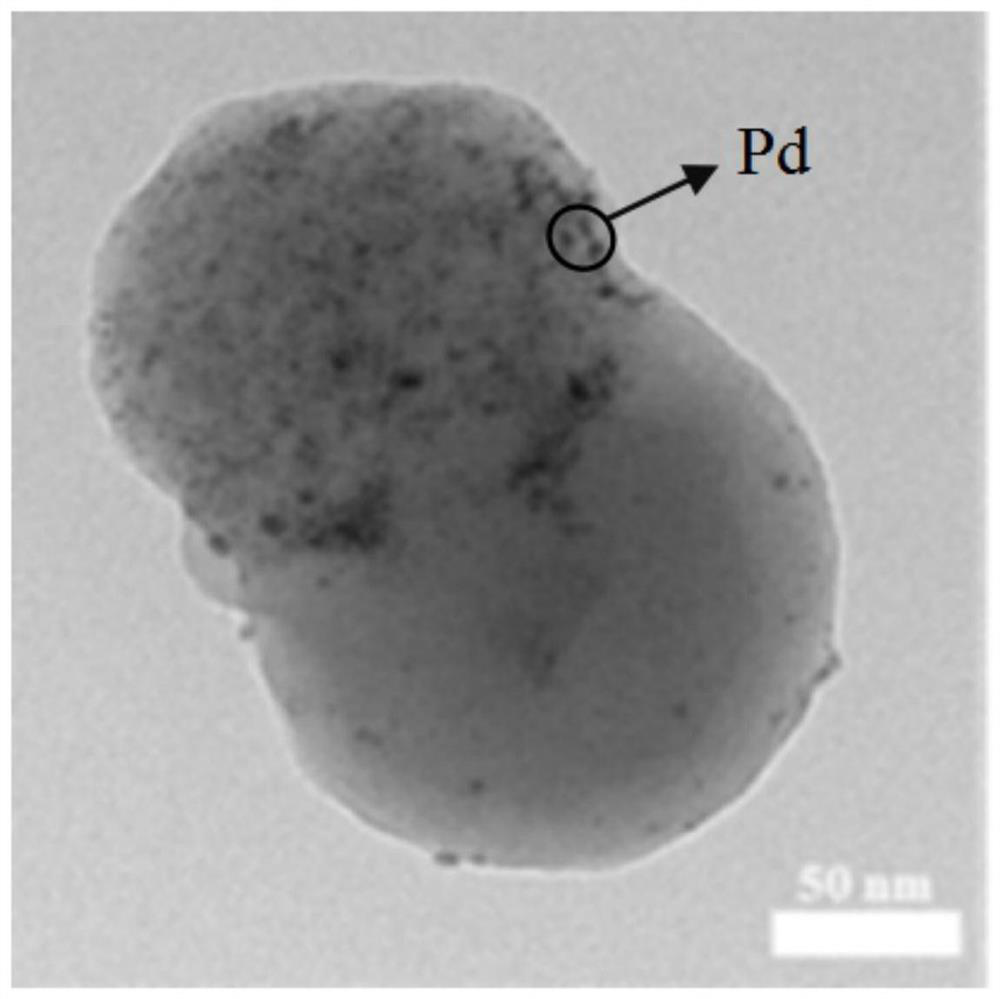

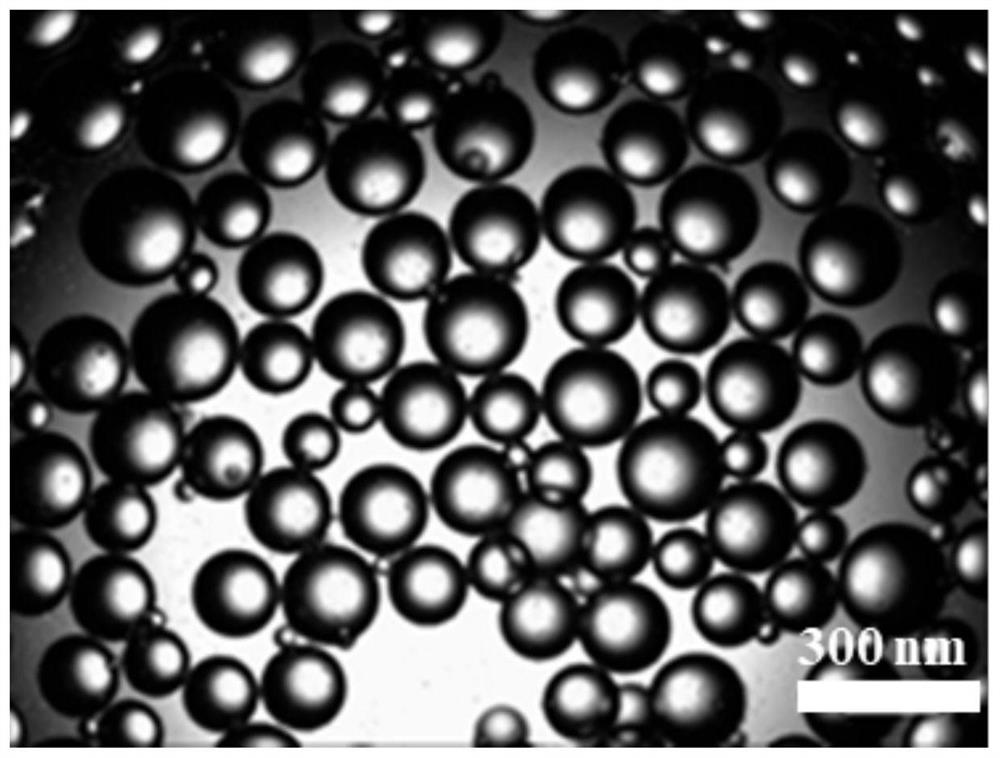

[0043] Weigh 0.13g sodium dodecyl sulfate, 125mL H 2 O in the reactor, mechanical stirring and dissolving at room temperature, add 10.42g styrene, 0.33g divinylbenzene simultaneously, continue to pass N 2 After 30 min, the temperature of the reaction system was raised to 80 °C, a mixture of 0.19 g potassium persulfate and 19 mL water was slowly added dropwise, and the polymerization was performed at a constant temperature for 10 h. After the reaction, after the reaction solution was lowered to room temperature, 60 mL of H was added. 2 O, 6.04g p-chloromethylstyrene, 0.12g divinylbenzene, continue to swell for 4h, then heat up to 60°C, and add dropwise 0.24g potassium persulfate, 0.18g NaHSO 3 with 15mL H 2 The mixed solution of 0, continuous reaction 5h obtains seed emulsion;

[0044] Weigh 10g of the above seed emulsion, 10g of H 2 O and 0.33g of sodium dodecyl sulfate were placed in the reactor, mechanically stirred until the sodium dodecyl sulfate was dissolved, then th...

Embodiment 2

[0047] Weigh 0.13g sodium dodecyl sulfate, 125mL H 2 O in the reactor, mechanical stirring and dissolving at room temperature, add 10.42g styrene, 0.33g divinylbenzene simultaneously, continue to pass N 2 After 30 min, the temperature of the reaction system was raised to 80 °C, a mixture of 0.19 g potassium persulfate and 19 mL water was slowly added dropwise, and the polymerization was performed at a constant temperature for 10 h. After the reaction, when the reaction solution was lowered to room temperature, 60 mL of H was added. 2 O, 6.04g p-chloromethylstyrene, 0.12g divinylbenzene, continue to swell for 4h, then heat up to 60°C, and add dropwise 0.24g potassium persulfate, 0.18g NaHSO 3 with 15mL H 2 The mixed solution of O is continuously reacted for 5h to obtain seed emulsion;

[0048] Weigh 20g above-mentioned seed emulsion, 20g H 2 O and 0.66g sodium dodecyl sulfate were placed in the reactor, mechanically stirred until the sodium dodecyl sulfate was dissolved, th...

Embodiment 3

[0050] Weigh 0.22g sodium dodecyl sulfate, 125mL H 2 O in the reactor, mechanical stirring and dissolving at room temperature, add 20.83g styrene, 0.33g divinylbenzene simultaneously, continue to pass N. 2 After 30 min, the temperature of the reaction system was raised to 80 °C, and a mixture of 0.4 g of potassium persulfate and 30 mL of water was slowly added dropwise, and the polymerization was carried out at a constant temperature for 12 h. After the reaction, when the reaction solution was lowered to room temperature, 100 mL of H was added. 2 O, 12.2g p-chloromethylstyrene, 0.25g divinylbenzene, continue to swell for 6h, then heat up to 60°C, and dropwise add 0.24g potassium persulfate, 0.18g NaHSO 3 with 15mLH 2 The mixed solution of O is continuously reacted for 8h to obtain seed emulsion;

[0051] Weigh 20g of the above seed emulsion, 40g of H 2 O and 1.32g sodium dodecyl sulfate were placed in the reactor, mechanically stirred until the sodium dodecyl sulfate was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com