High-power variable ultraviolet light source curing device and curing method thereof

A technology of ultraviolet light source and curing device, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc., which can solve the problems of fast decay of mercury light, troublesome replacement of lamp beads, short life, etc., and achieve the intensity of light source irradiation High, improve the effect of applicability and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, a clear and complete description will be made below in conjunction with the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, and Not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

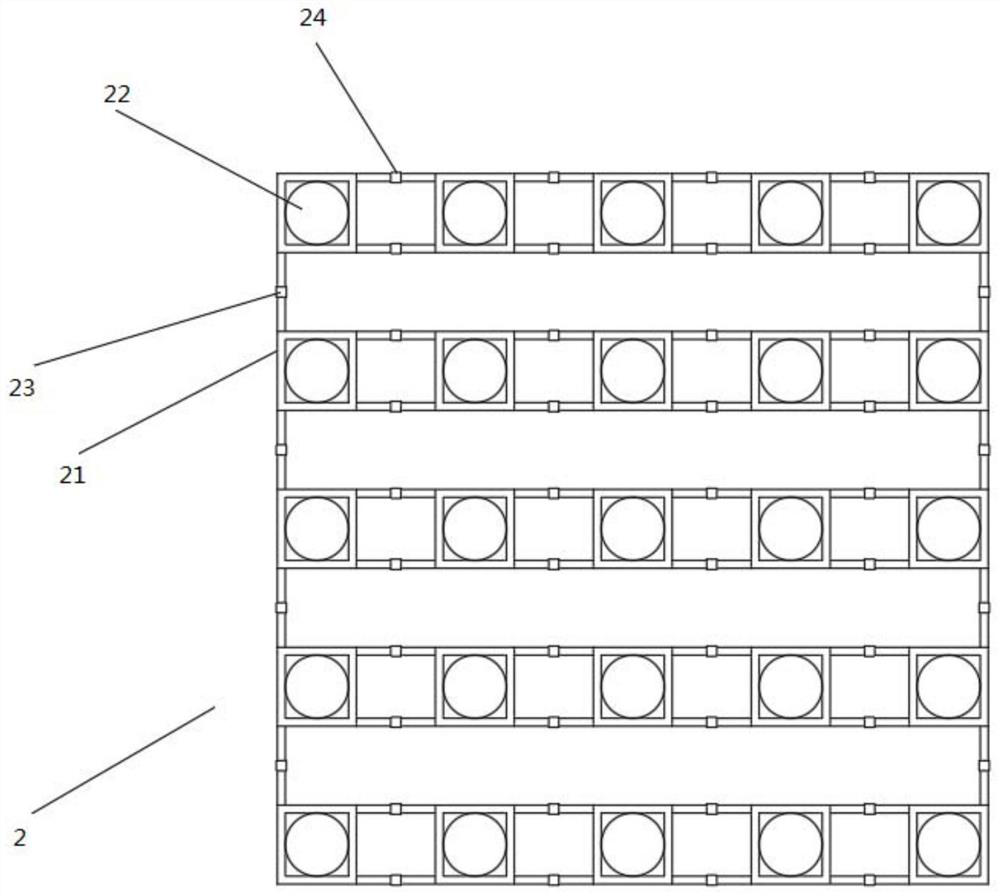

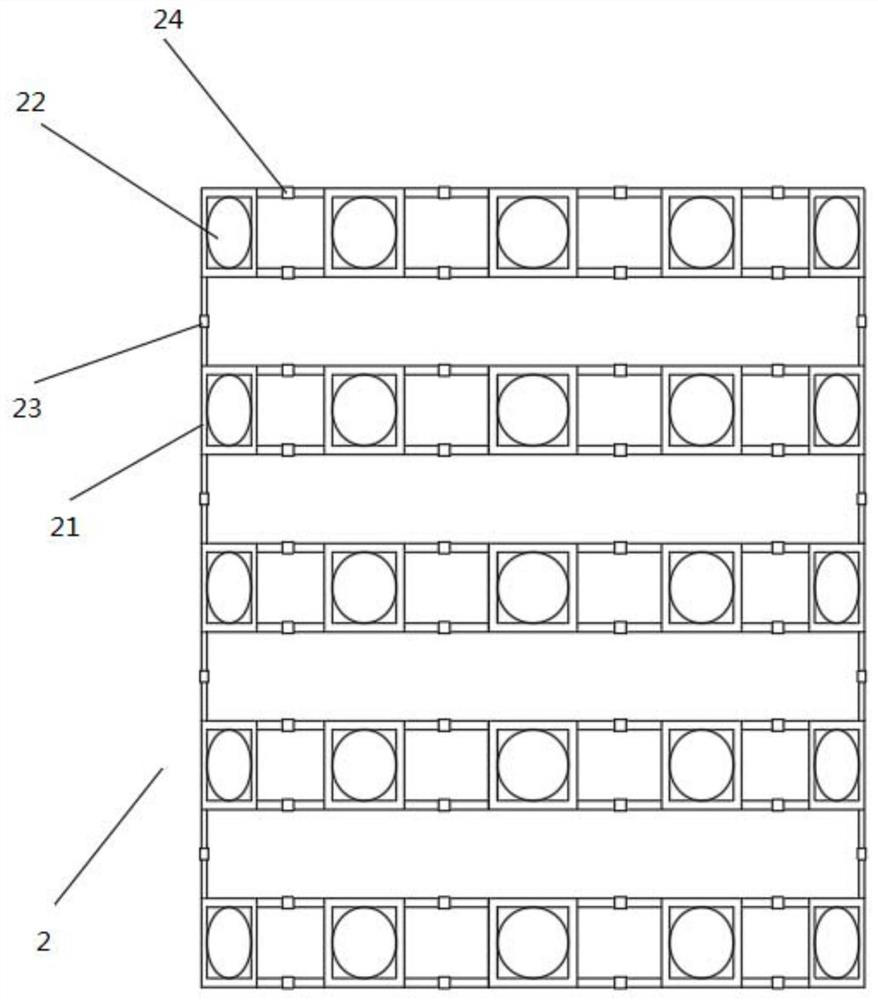

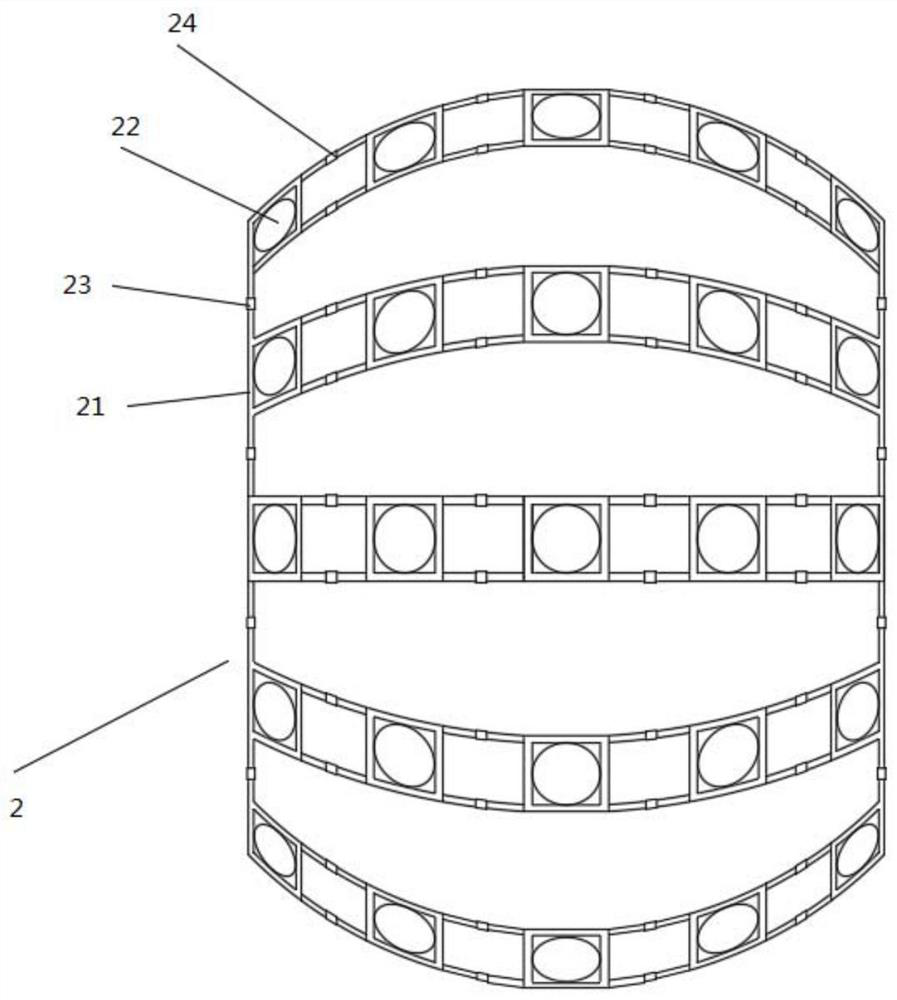

[0045] The high-power variable ultraviolet light source curing device of the preferred embodiment of the present invention The high-power variable ultraviolet light source curing device is as follows: figure 1 shown, see Figure 2-8 , including a flat concentrating plate 11, a first raised concentrating plate 12, a second raised concentrating plate 13 and a light source module 2, the light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com