Laser processing device and method for realizing super-hydrophobic metal micro parts

A laser processing and micro-parts technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as clamping difficulties, affecting the forming accuracy and wetting effect of micro-parts, and achieve convenient operation, precision and controllability The effect of microstructure forming and avoiding secondary clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

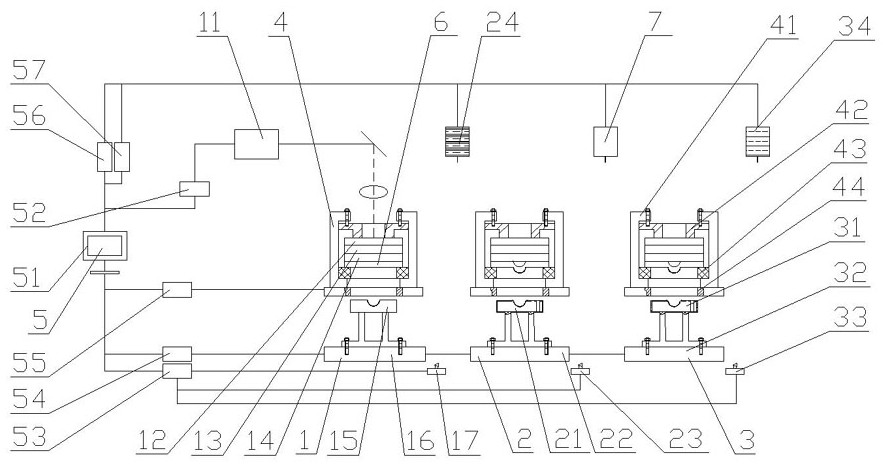

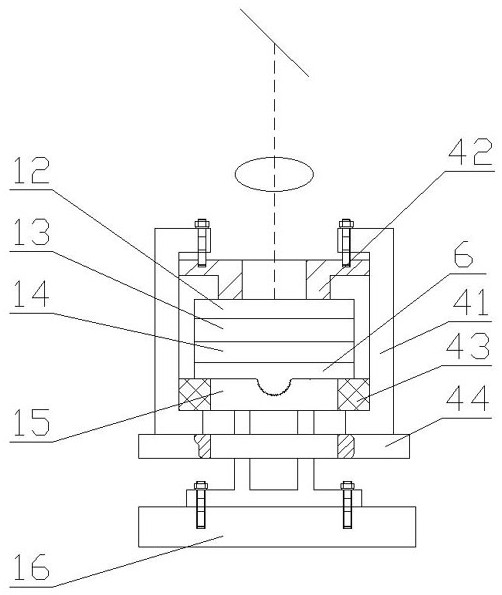

[0046] Such as figure 1 , 2 , 3, 4, 5 and 8, a laser processing device for realizing superhydrophobic metal micro parts, including a forming system 1, a modification system 2, a cleaning system 3, a clamp assembly 4 and a control assembly 5, the clamp The assembly 4 clamps the workpiece 6 to be processed and passes through the forming system 1, the finishing system 2 and the cleaning system 3 in sequence, and the control assembly 5 controls the forming system 1, the finishing system 2, the cleaning system 3 and the fixture assembly 4 respectively;

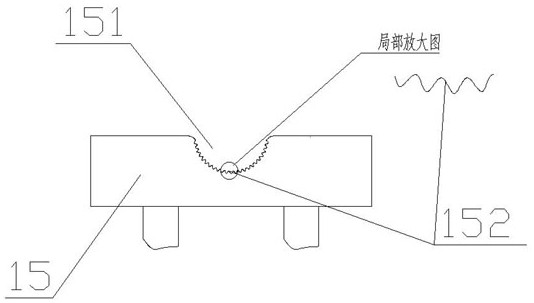

[0047] The forming system 1 includes a laser assembly 11, a constraining layer 12, an absorbing layer 13, a soft film 14, a forming module 15, a forming module support platform 16 and a forming module positioning assembly 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com