Automatic welding device and process method for finned radiator reinforcing ribs

An automatic welding and reinforcing rib technology, applied in auxiliary devices, welding equipment, metal processing and other directions, can solve problems such as the welding efficiency problem of chip radiator reinforcing ribs, and achieve the effect of improving welding efficiency and welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

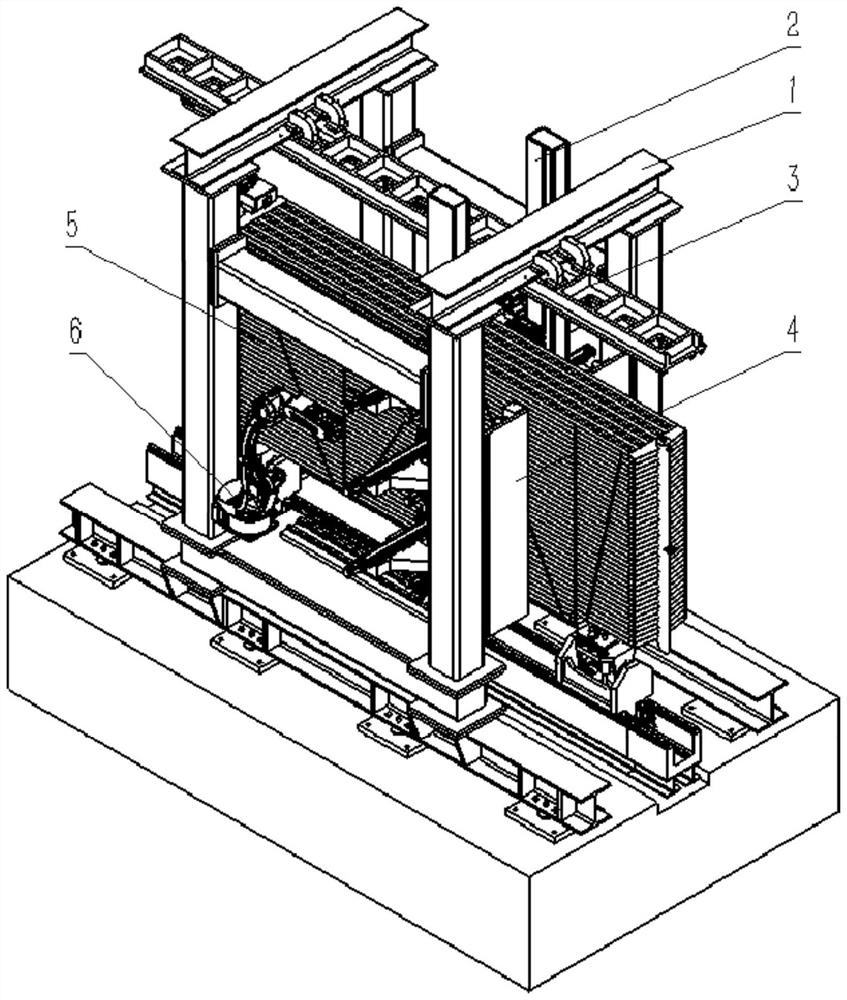

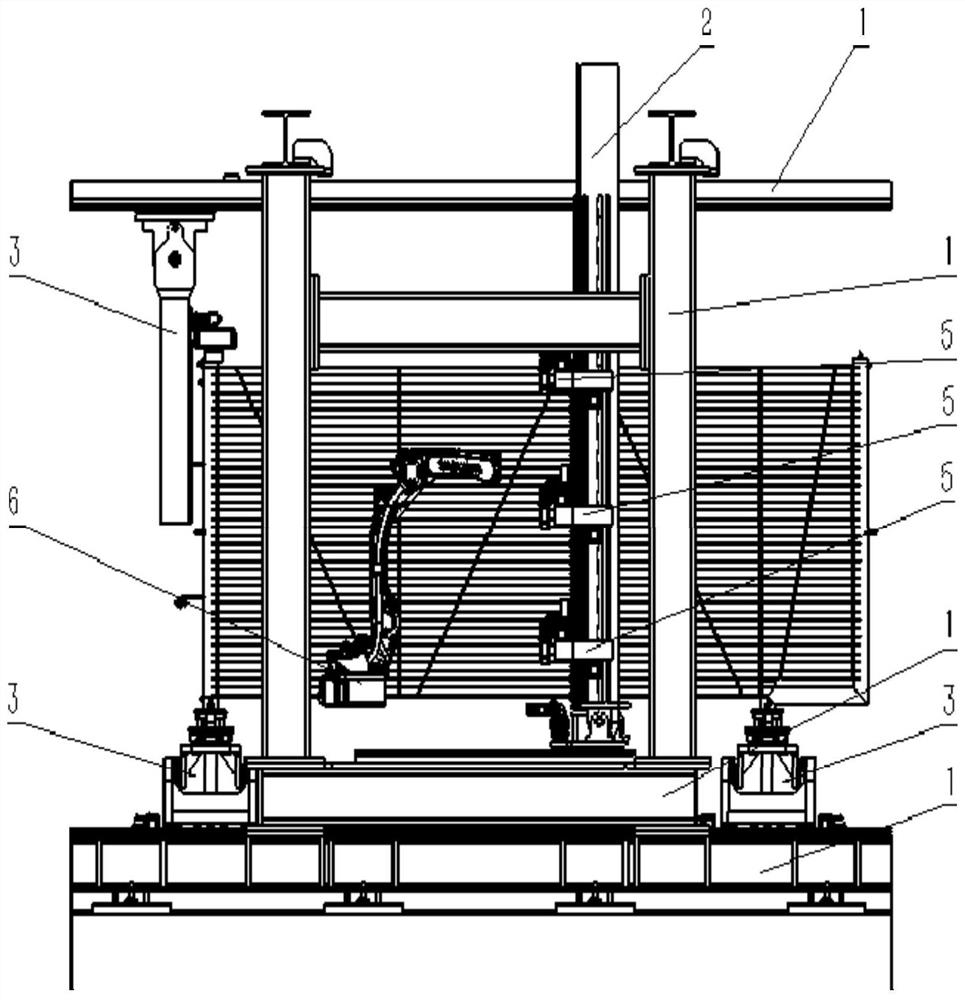

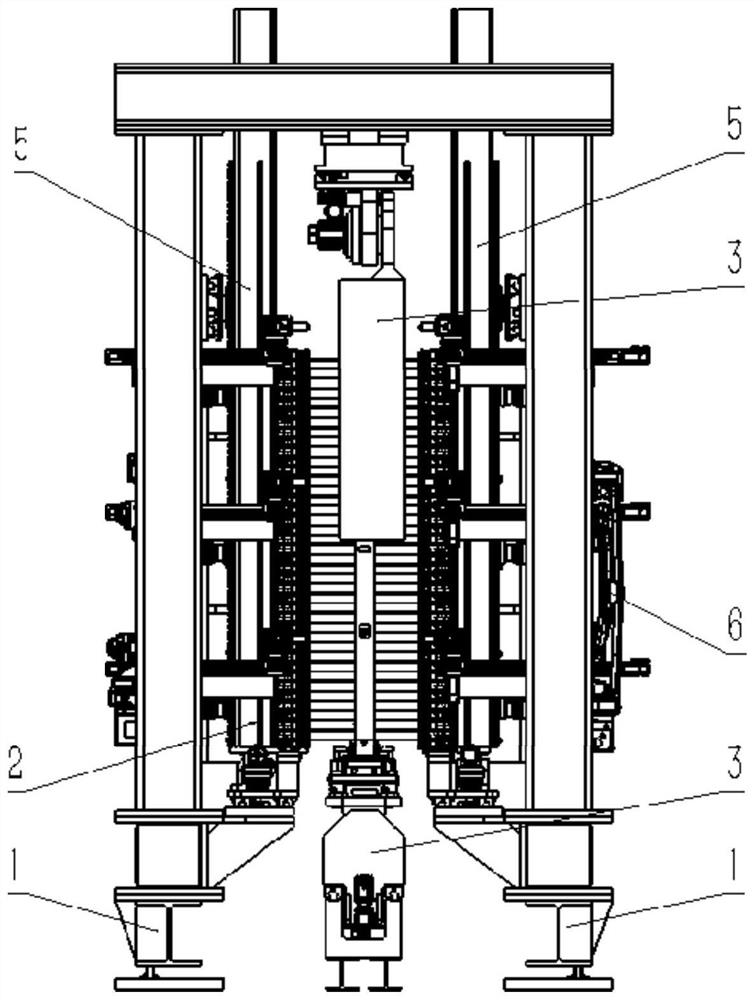

[0028] The invention relates to an automatic welding device for ribs of sheet radiators. The device includes a steel structure foundation 1, a swing arm type equidistant positioning device 2, a three-dimensional transfer device 3, a shape detection device 4, and a shape correction and positioning of the ribs. Device 5, robot welding system 6; the steel structure foundation 1 is fixedly connected with the swing arm type equidistant positioning device 2, the three-dimensional transfer device 3, the shape detection device 4 and the robot welding system 6, and the connection position is as follows figure 1 As shown, the reinforcing rib shape correcting positioning device 5 is slidingly connected with the swing arm type equidistant positioning device 2 .

[0029]The swing arm type equidistant positioning device 2 includes a base slide base 7, a swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com