Process for installing and positioning double-rudder sleeve and tail casting in segmented construction stage

A segmented construction, installation and positioning technology, applied to ships and other directions, can solve problems such as the inability of scaffolders to set up units in advance, the difficulty of precise control, and the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

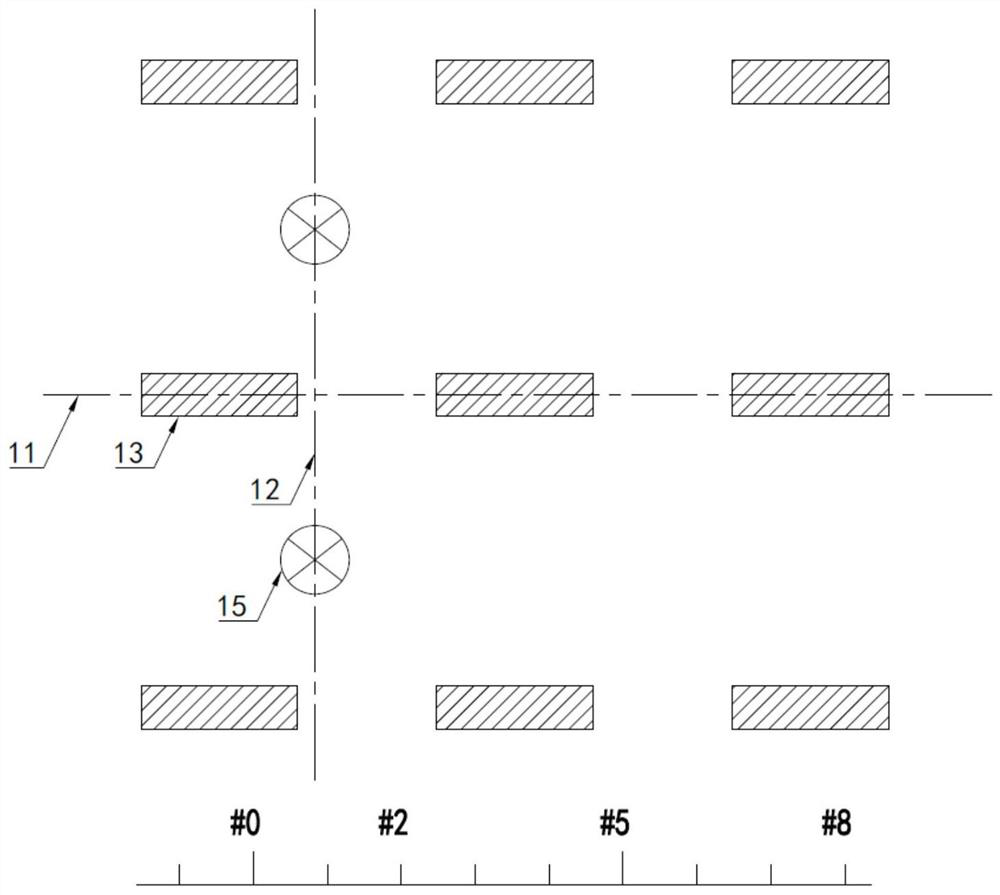

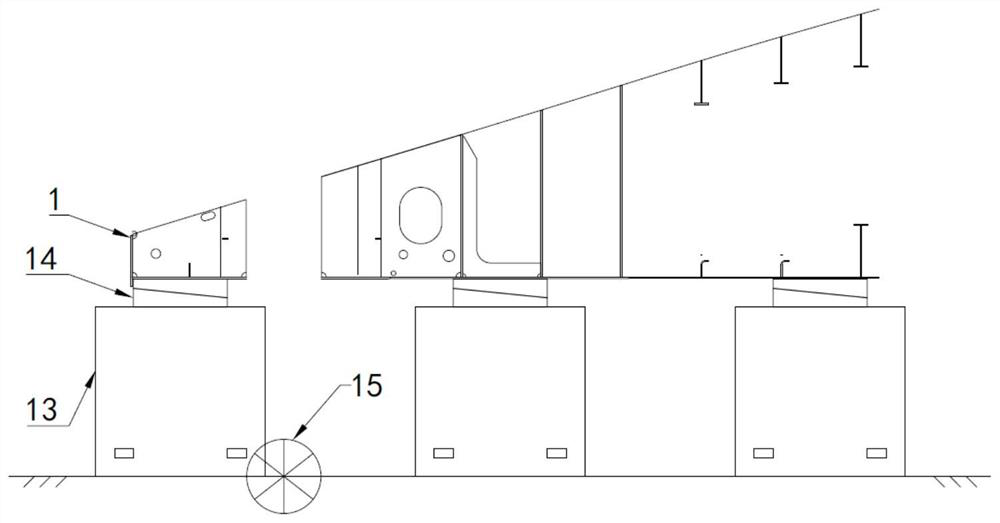

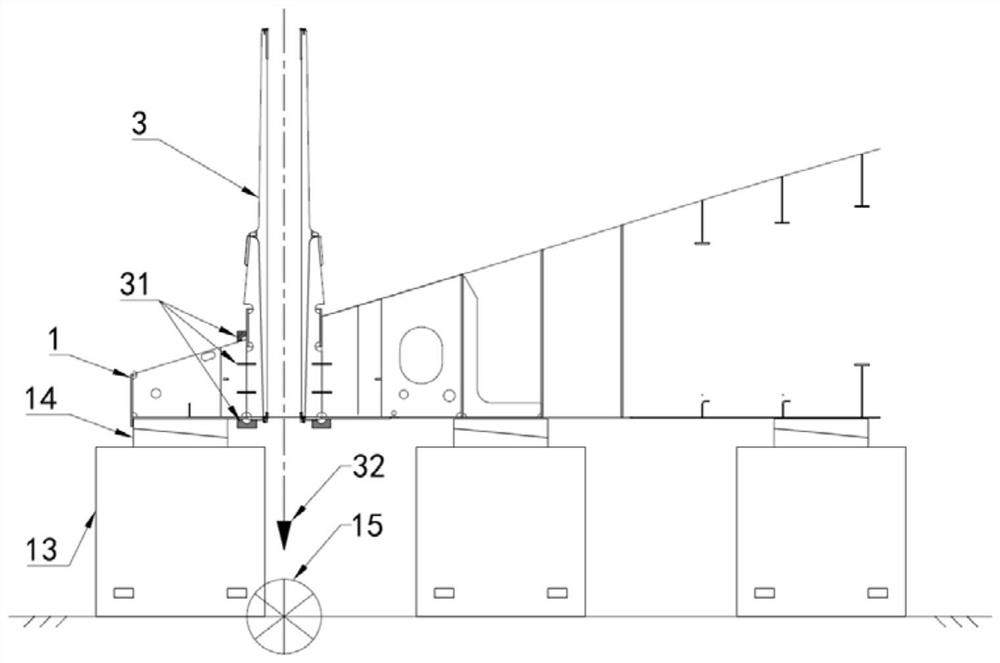

[0045] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown in -8, a process for the installation and positioning of the double rudder sleeve 3 and the tail casting in the stage of segmented construction includes the following steps:

[0046] Step 1: Build DK1A assembly 1, including frame surface level calibration, scribing, positioning, assembly, welding, and the whole process is precisely controlled tracking, using bulk outer plates, turning over to complete the electric welding of internal components and outer plates , Turn over and go back.

[0047] Due to the large number of bulk outer plates, the anti-deformation amount of 15mm is set. The welding principle is butt welding first, then vertical fillet welding, and finally flat fillet welding. Outside, first up and then down, the welding method from the center to the surrounding is adopted to reduce welding deformation. The outer plate and the upper tire plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com