Ceramic raw material storage numerical control intelligent control device and method

A technology of intelligent control and ceramic raw materials, which is applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve problems affecting product quality, affecting the quality of stored powder, etc., to achieve streamlining, high efficiency, accurate feeding and batching, and reduce Production cost, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing:

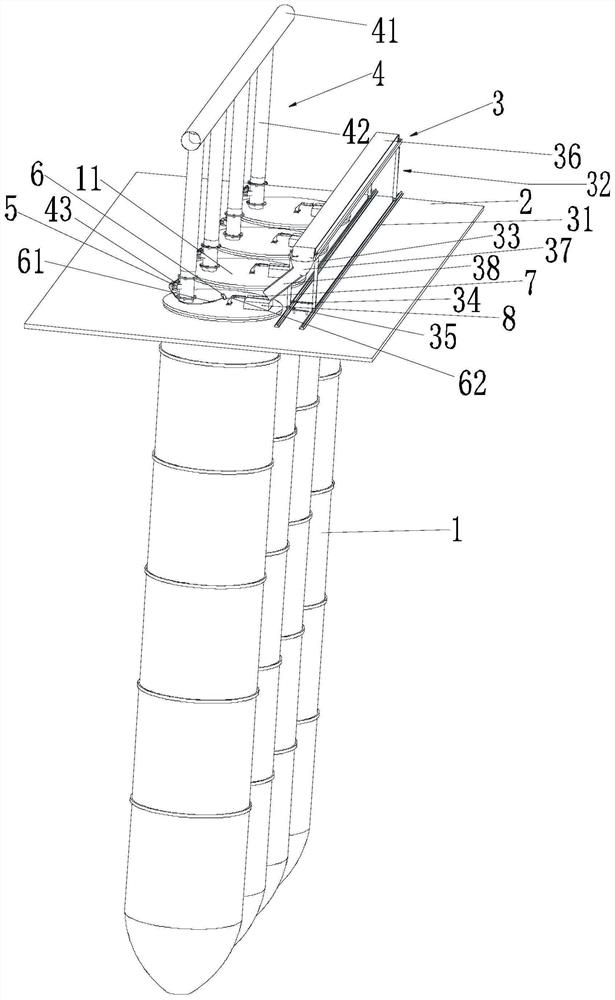

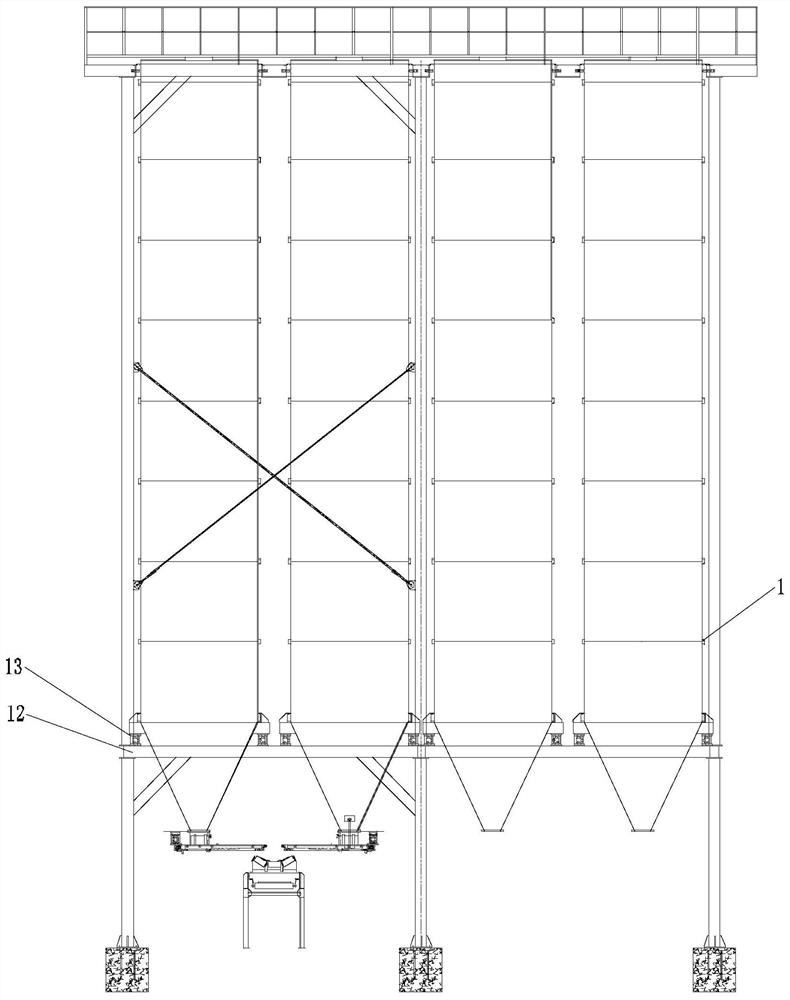

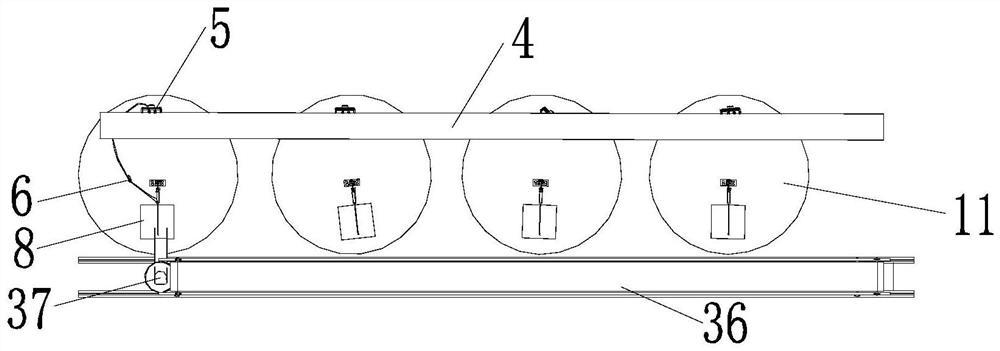

[0030] see Figure 1 to Figure 3 As shown, the ceramic raw material storage numerical control intelligent control device includes several parallel silos 1, and the multiple parallel silo top covers 11 vertically pass through the perforation of the silo platform, and are located on the side of the silo top cover 11. The powder conveying mechanism 3 is fixed on the silo platform 2, and the moisture discharge pipe 4 is respectively inserted into the corresponding silo 1 through a plurality of silo top covers 11. The moisture discharge pipe 4 is provided with a flap valve, located on the flap The outer wall of the moisture discharge pipe 4 at the valve part is fixed with an electronic pneumatic cylinder 5, and the flap valve control rod 43 passing through the wall of the moisture discharge pipe 4 is connected to the electronic pneumatic cylinder 5, and the electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com