Full-water-soluble chelated particle microelement water-soluble fertilizer and preparation process thereof

A technology for chelating trace elements and trace elements, which is applied in fertilizer mixtures, solid/semi-solid fertilizers, fertilization devices, etc., can solve the problems of narrow and rare use, and achieve the effect of improving absorption and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A fully water-soluble chelated granular trace element water-soluble fertilizer according to the present invention comprises a composite chelated trace element component and a water-soluble filler, and the mass ratio of the composite chelated trace element component to the water-soluble filler is 2:3 ;

[0042] Wherein the compound type chelated trace element component comprises the following components according to the mass fraction:

[0043] EDTA 4%;

[0044] Citric acid 5%;

[0045] Water soluble chitin 3%;

[0046] Boron zinc iron manganese copper molybdenum material 88%.

[0047] Boron, zinc, iron, manganese, copper and molybdenum materials include the following components: zinc sulfate heptahydrate, sodium iron ethylenediamine tetraacetate, copper sulfate pentahydrate, manganese sulfate monohydrate, molybdenum chelated with EDTA;

[0048] The proportion of each component in the boron zinc iron manganese copper molybdenum material in the composite chelated trace e...

Embodiment 2

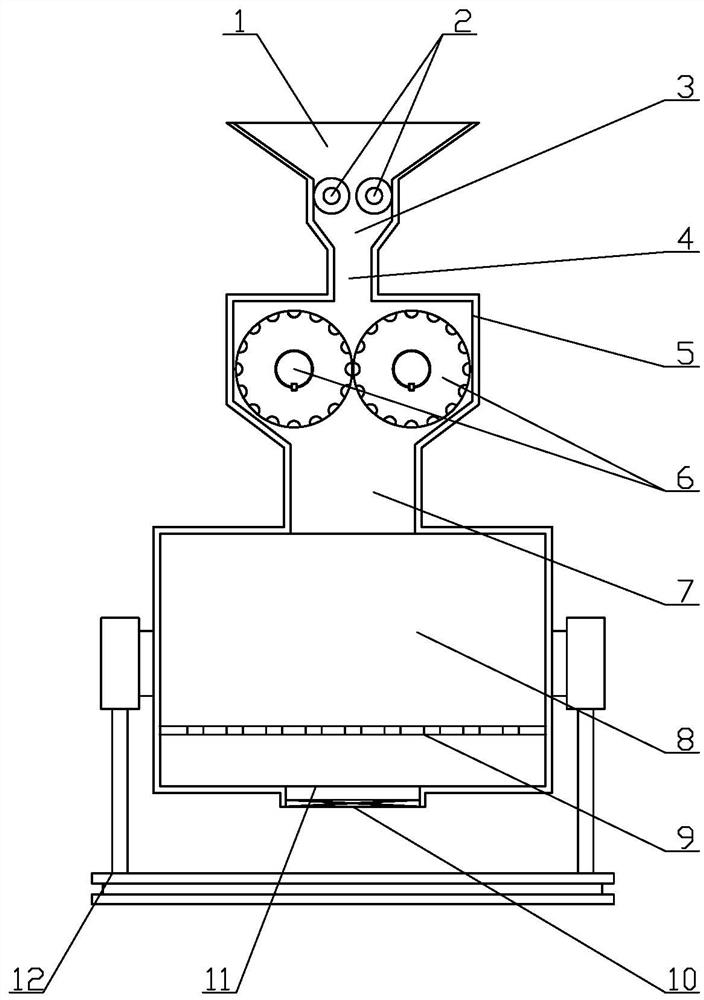

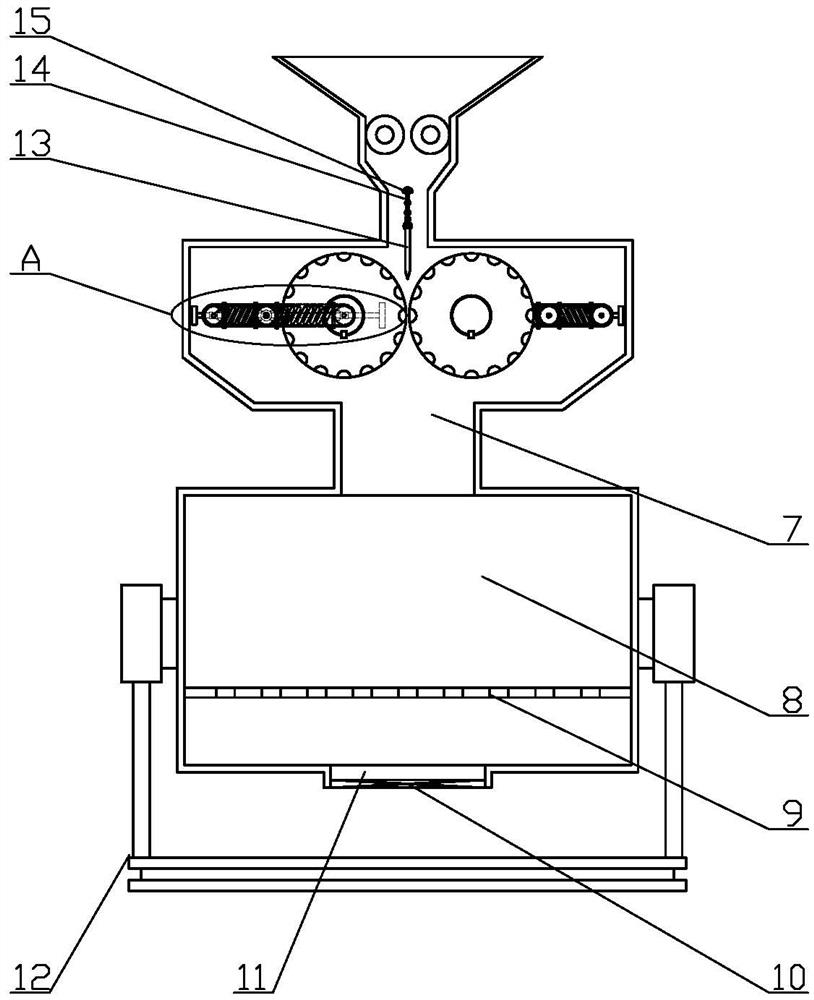

[0062] Such as figure 1 As shown, the pair-roll extrusion granulator includes a support frame, and the support frame includes a hopper, a primary molding device, a secondary molding device and a material collection box in sequence from top to bottom.

[0063] The feeding hopper is in the shape of a funnel with an open measuring end and a large top and a small bottom. The primary molding device is connected below the feeding hopper; the primary molding device includes a primary forming outer cylinder, and at least one pair of sheet material forming pairs are arranged in the primary forming outer cylinder. The two ends of the pair of sheet material forming rollers are respectively installed on the side wall of the primary forming outer cylinder through the bearing seat; the sheet material extrusion forming gap is set between the sheet material forming pair of rollers arranged in pairs; The outer roll surface of the material forming pair of rollers is a smooth cylindrical surface...

Embodiment 3

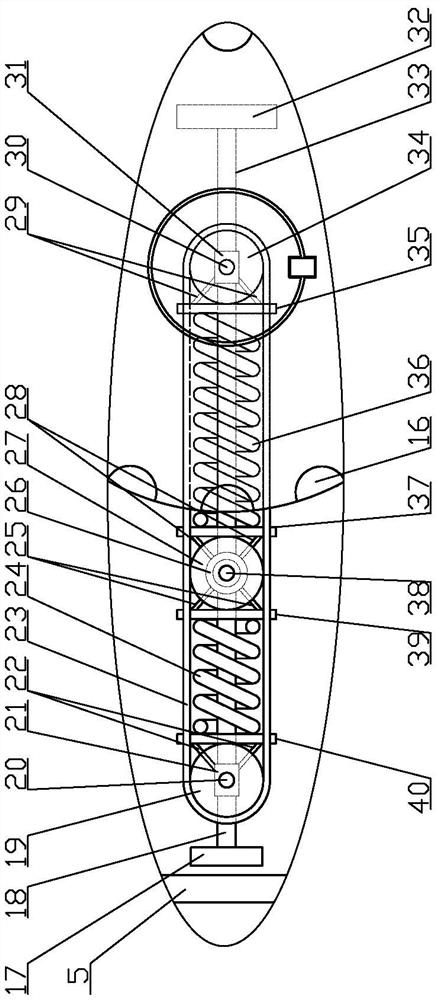

[0069] Such as figure 2 and 3 As shown, an adjustment board structure is set in the upper feeding pipe. The adjustment board structure includes a fixed guide rod and a sliding guide plate. The number of fixed guide rods is more than two. The upper ends of each fixed guide rod are connected to the guide rod bracket and It is fixed on the side wall of the upper feeding pipe through the guide rod bracket; several guide rod sockets are opened on the upper end of the sliding guide plate, and the sliding guide plate is set on the fixed guide rod through each guide rod socket; the guide plate is installed on the side of the sliding guide plate A bar-shaped slide hole is set on the side wall of the upper feed pipe, and the guide plate handle is inserted into the bar-shaped slide hole; moving the guide plate handle up and down can drive the sliding guide plate to move up and down along the fixed guide rod; when the sliding guide plate is at At the upper limit, the sliding guide plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com