High-polarity UV coating material and preparation method thereof

A high-polarity, coating technology, used in polyester coatings, coatings, etc., can solve problems such as poor adhesion and poor adhesion, and achieve the effects of strong polarity, improved utilization, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

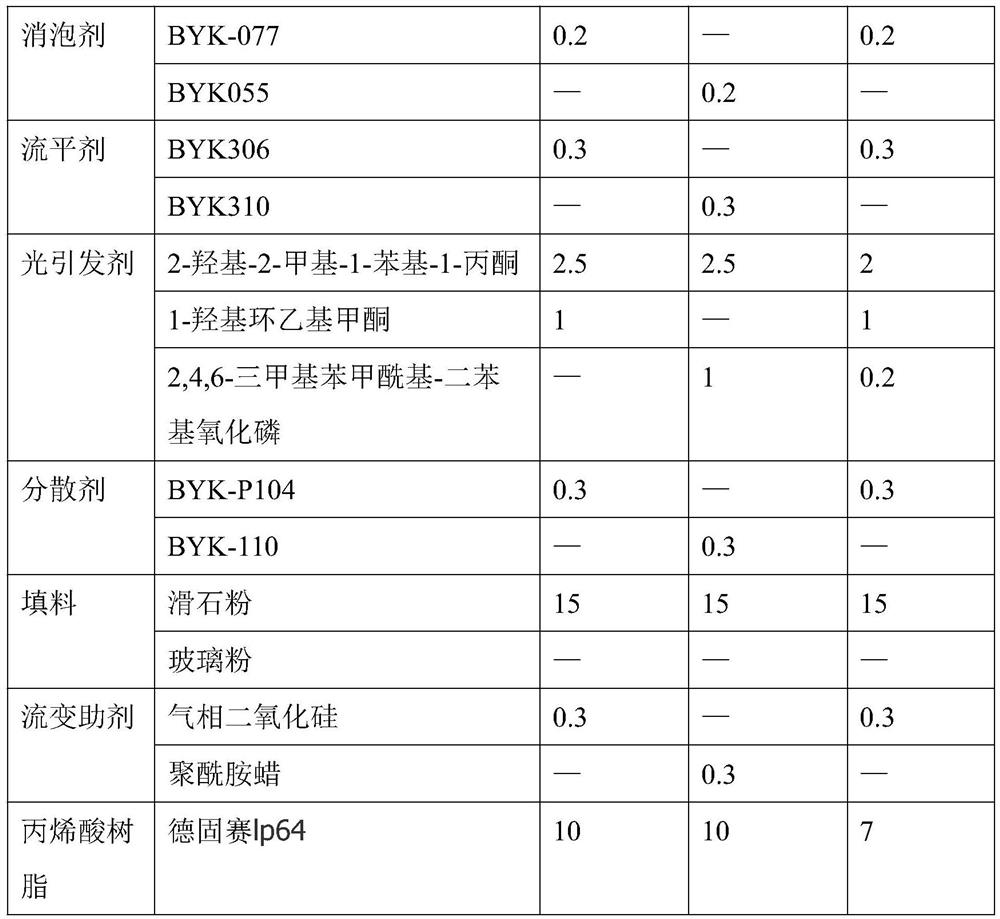

[0023] The formula is as shown in Table 1:

[0024]

[0025]

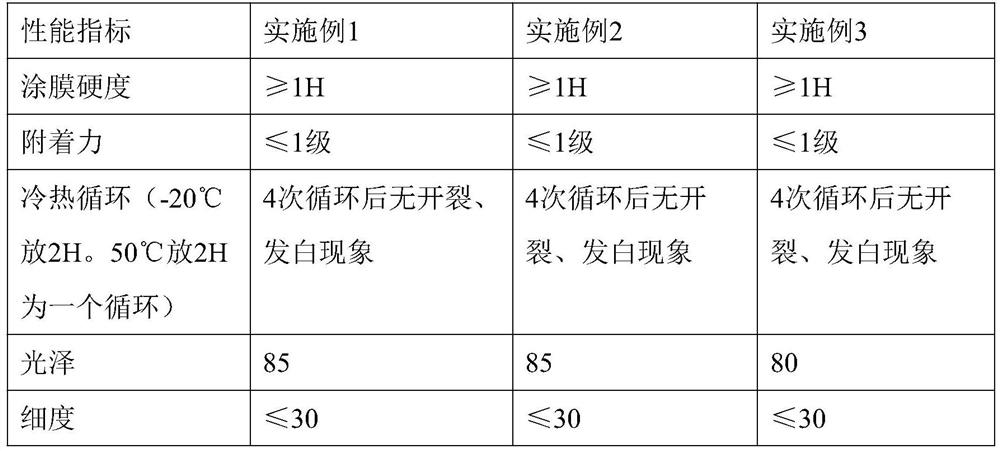

[0026] Table 2 performance index of the present invention

[0027]

[0028] According to the formula in Table 1, the high polarity UV coating material is prepared by the following method: uniformly disperse the UV resin, reactive diluent, and photoinitiator at a low speed in sequence, and disperse the dispersant, leveling agent, and defoamer at a low speed in sequence for 5 Minutes (500 rpm) after adding fillers, rheology additives, acrylic resin high-speed dispersion for 30 minutes (1000 rpm) to a fineness of ≤ 30 microns after filtration to obtain high-polarity UV coating materials.

Embodiment 4-6

[0030] The formula is shown in Table 3

[0031]

[0032]

[0033] Table 4 performance index of the present invention

[0034]

[0035] According to the formula in Table 3, the high polarity UV coating material is prepared by the following method: uniformly disperse the UV resin, reactive diluent, and photoinitiator at a low speed in sequence, and disperse the dispersant, leveling agent, and defoamer at a low speed in sequence for 5 Minutes (500 rpm) after adding fillers, rheological additives, acrylic resin high-speed dispersion for 30 minutes (1000 rpm) to a fineness of ≤ 20 microns after filtration to obtain high-polarity UV coating materials.

[0036] The high-polarity UV coating material obtained by the above examples is suitable for the field of wood furniture, has high production efficiency, no organic volatile emissions, and has good adhesion to different substrates and paint without polishing. The film is strong in adhesion, the product has strong versatility...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap