Equipment for metal heat treatment quenching

A metal heat treatment and equipment technology, applied in heat treatment equipment, heat treatment process control, quenching device, etc., can solve the problems of unable to clamp volume, small fixed shape metal, etc., and achieve the effect of improving practicability and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

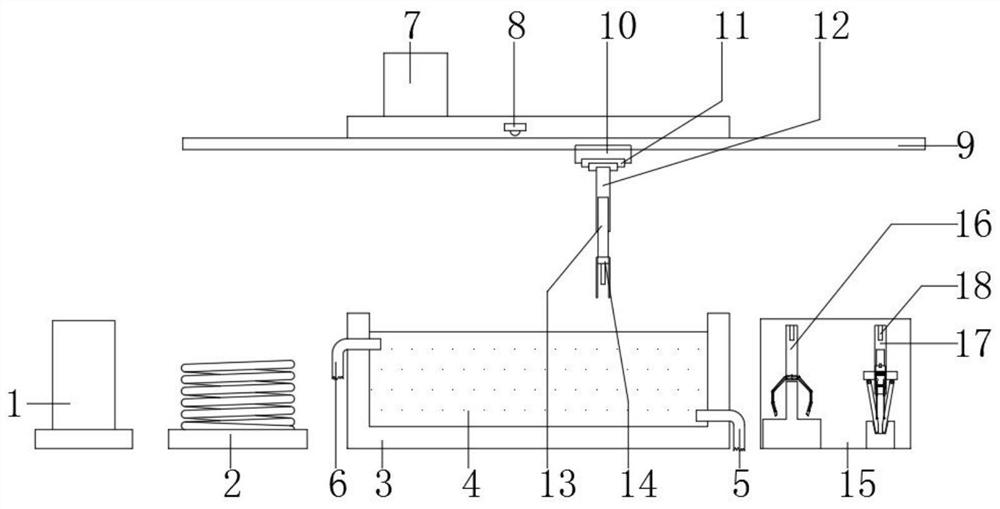

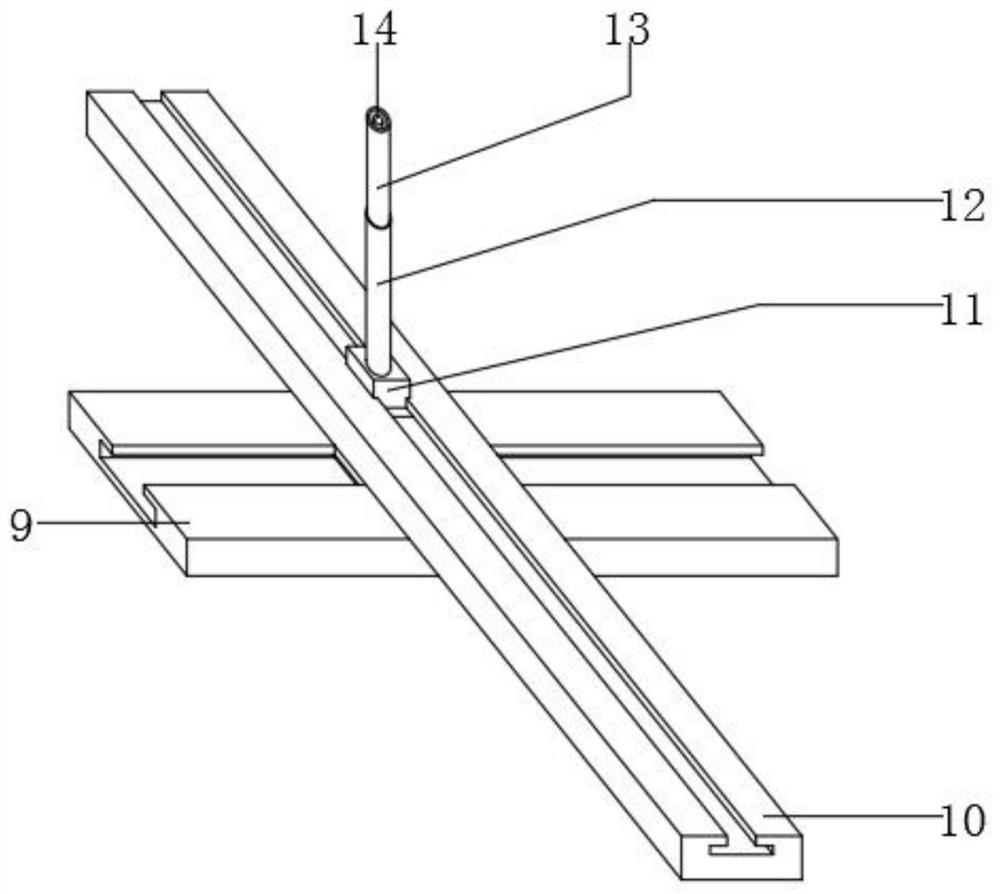

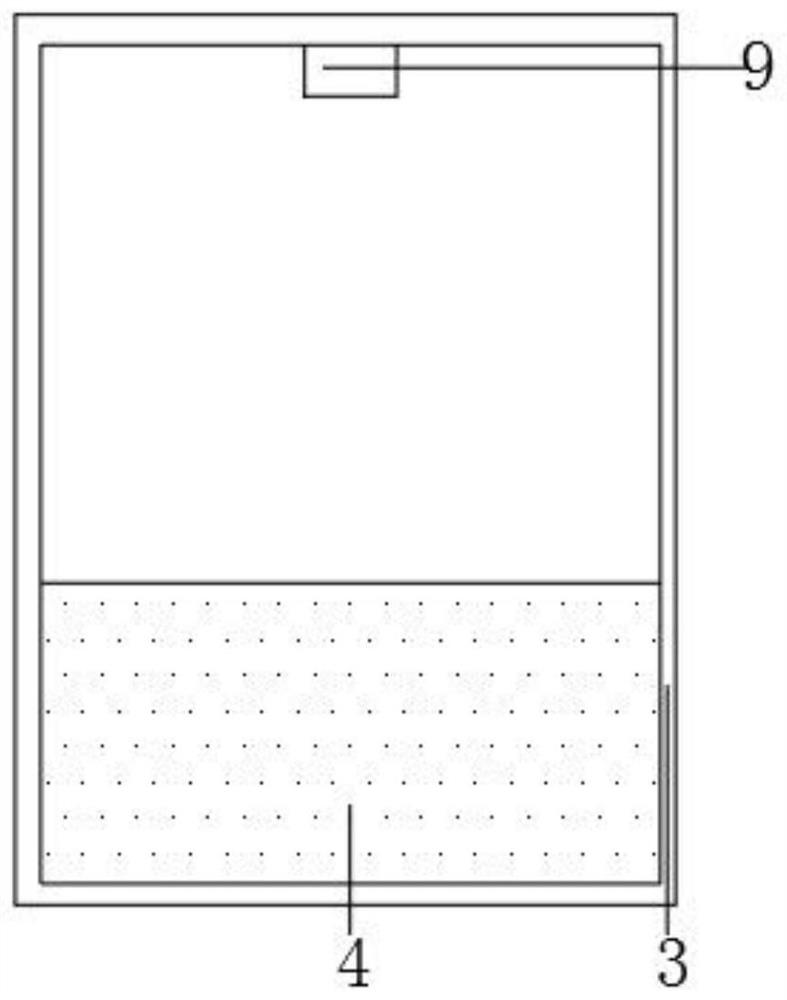

[0026] refer to Figure 1-5 , a kind of equipment for metal heat treatment and quenching, including a power supply 1, a coil 2 is arranged behind the power supply 1, a casing 3 is arranged behind the coil 2, a quenching liquid 4 is arranged on the inner surface of the casing 3, and the casing 3 One side is provided with a liquid inlet pipe 5, and the liquid inlet pipe 5 guides the heated quenching liquid 4 into the housing 3, and the other side of the housing 3 is provided with a liquid outlet pipe 6, and the upper end of the housing 3 is provided with an air pump 7 , the air pump 7 can make the suction head 14 suck the first mechanical arm 16 or the second mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com