Preparation method of indoor fireproof door

A technology of fire doors and fire door core panels, applied in the field of fire doors, can solve the problems of inconvenient automatic production, poor flame retardant effect, and failure to meet the standard fire resistance time, and achieve good sealing effect, improved strength, and improved fire resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples.

[0030] The manufacturer of the high-performance flame-retardant synthetic board used in the following examples is Xinyang Meilizhenhao Straw New Material Technology Co., Ltd.; the manufacturer of the perlite fire door core board is Zhongtian Environmental Protection (Yancheng) Co., Ltd.; Fireproof board and density board are conventional models.

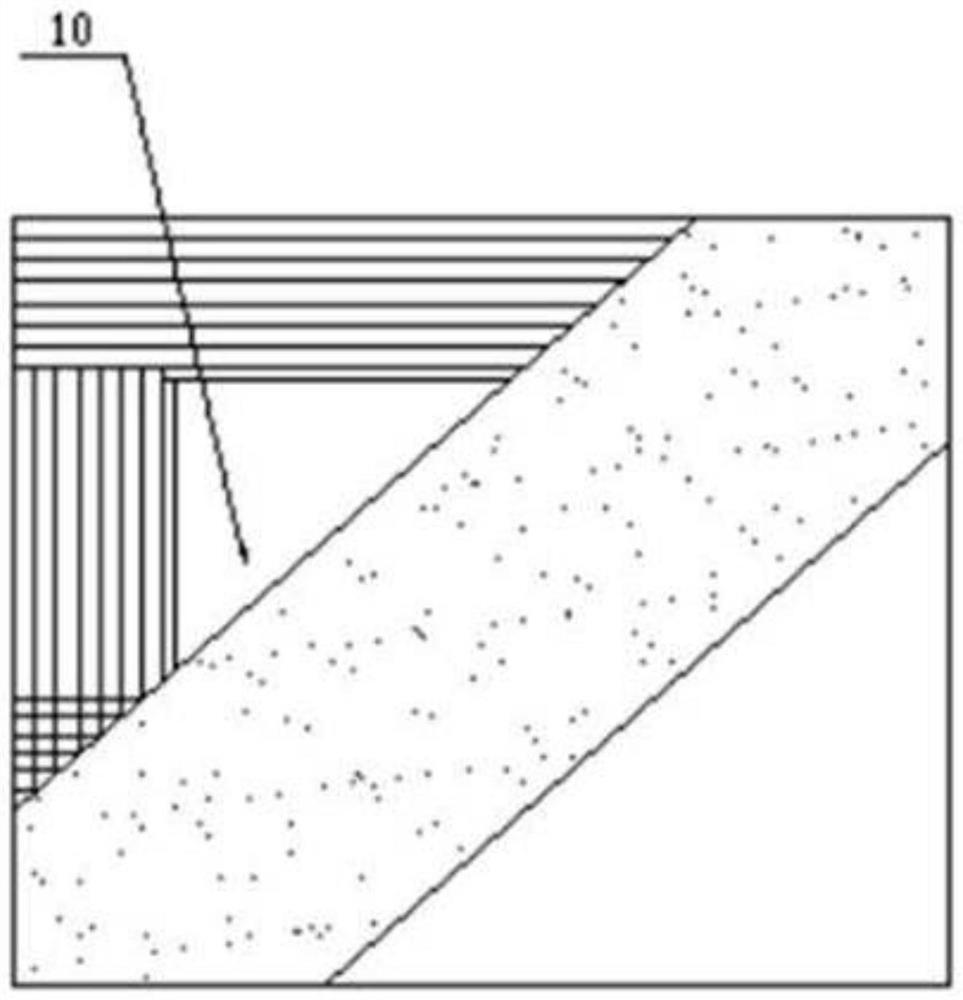

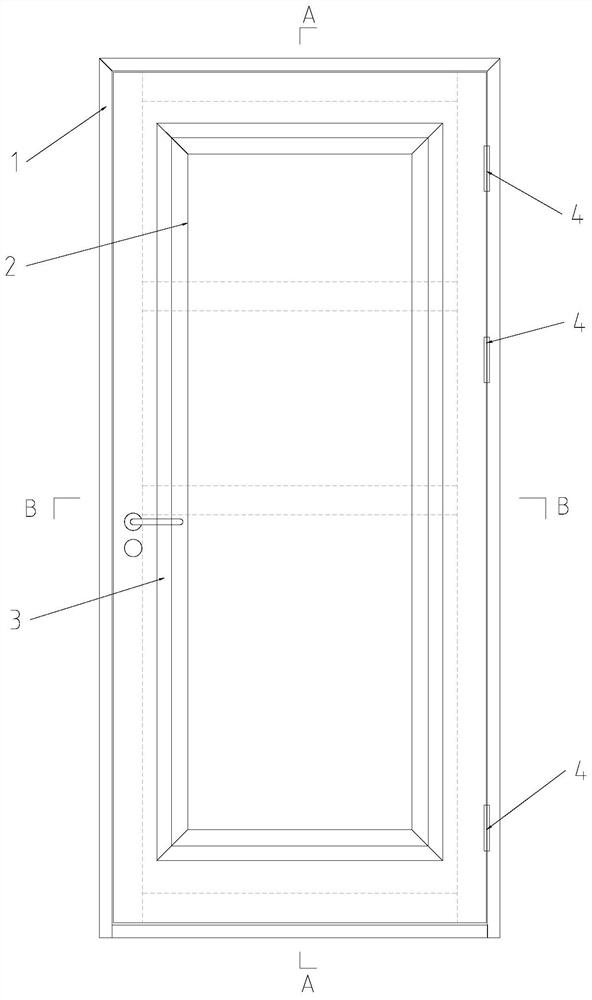

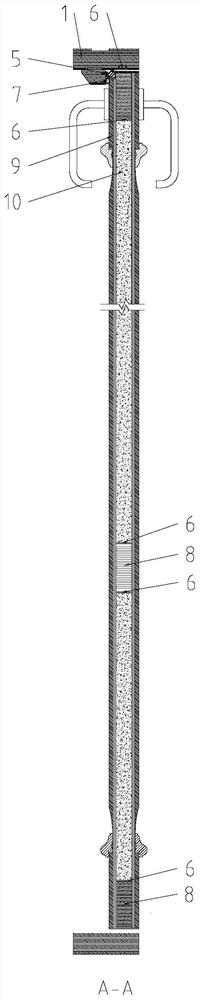

[0031] The indoor fireproof door provided by the present invention is provided with a door frame 1 and a door leaf 2. The cross section of the door leaf 2 is provided with a door leaf frame 8, a fireproof expansion seal 6 and a perlite fireproof door core board 10 in sequence. Between the door frame 1 and the door leaf 2 is a The gap, the door frame 1 and the door leaf 2 are connected by a fireproof hinge 4, the door frame 1 is provided with a soft magnetic suction and a magnetic sealing strip 5 at the contact position with the door leaf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com