A kind of high alumina refractory brick and preparation method thereof

A refractory brick, high-aluminum technology, applied in the field of building materials, can solve the problems of poor material performance, reduced performance, poor use timeliness, etc., to achieve excellent corrosion resistance and oxidation resistance, improve heat resistance, and strong adhesion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

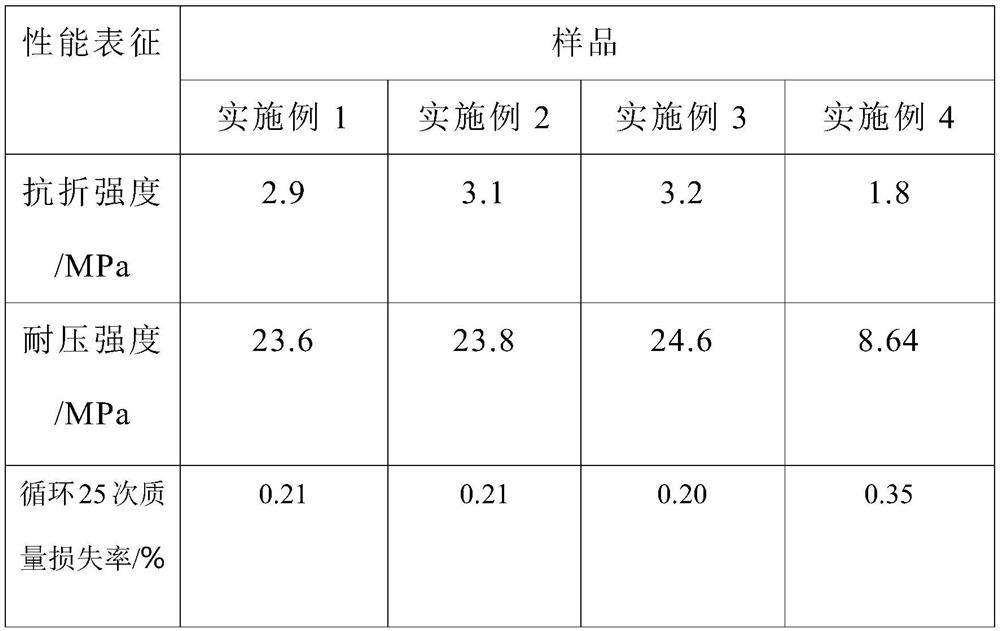

Examples

Embodiment 1

[0028] In terms of parts by weight, weigh 45 parts of mass fraction 60% ethanol, 3 parts of styrene monomer, 0.1 part of potassium persulfate and 0.1 part of sodium sulfite respectively and place them in a three-necked flask, stir and mix and exhaust the air with nitrogen, and control nitrogen ventilation. The feeding rate is 25mL / min. After the feeding is completed, stir and mix and place it at 75°C for 10 hours, then let it cool down to room temperature and collect the reaction solution. Stir the reaction solution with absolute ethanol at a mass ratio of 1:1. Mix and centrifuge, collect the lower precipitate and place it in an oven at 45°C, dry for 6 hours to obtain monodisperse polystyrene particles; weigh 45 parts of silica, 10 parts of alumina, 0.1 part of oxide Iron, 20 parts of quicklime, 5 parts of magnesium oxide, 1 part of potassium oxide and 1 part of sodium oxide were placed in a corundum crucible, stirred and mixed, heated and melted, heated at 5 °C / min to 1300 °C ...

Embodiment 2

[0030] In terms of parts by weight, weigh 47 parts of mass fraction 60% ethanol, 4 parts of styrene monomer, 0.1 part of potassium persulfate and 0.1 part of sodium sulfite respectively and place them in a three-necked flask, stir and mix and exhaust the air with nitrogen gas, and control the nitrogen gas flow. The feed rate is 27mL / min. After the feed is completed, stir and mix and place it at 77°C for 11 hours, then let it cool down to room temperature and collect the reaction solution. Stir the reaction solution with absolute ethanol at a mass ratio of 1:1. Mix and centrifuge, collect the lower precipitate and place it in an oven at 47°C, and dry it for 7 hours to obtain monodisperse polystyrene particles; in parts by weight, weigh 47 parts of silica, 12 parts of alumina, 0.1 part of oxide Iron, 25 parts of quicklime, 7 parts of magnesium oxide, 1 part of potassium oxide and 1 part of sodium oxide were placed in a corundum crucible, stirred and mixed, heated and melted, heat...

Embodiment 3

[0032] In parts by weight, weigh 50 parts of mass fraction 60% ethanol, 5 parts of styrene monomer, 0.2 part of potassium persulfate and 0.2 part of sodium sulfite respectively and place them in a three-necked flask. The feeding rate is 30mL / min. After the feeding is completed, stir and mix and place it at 80°C for 12 hours, then let it cool down to room temperature and collect the reaction solution. Stir the reaction solution with absolute ethanol at a mass ratio of 1:1. Mix and centrifuge, collect the lower precipitate and place it in an oven at 50°C for 8 hours to obtain monodisperse polystyrene particles; weigh 50 parts of silicon dioxide, 15 parts of aluminum oxide, and 0.2 parts of Iron, 30 parts of quicklime, 8 parts of magnesium oxide, 2 parts of potassium oxide and 2 parts of sodium oxide were placed in a corundum crucible, stirred and mixed, heated and melted, heated at 5 °C / min to 1500 °C for 3 hours, and the molten liquid was collected and watered Quench and cool, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com