A kind of tunnel construction method

A technology for tunnel construction and tunneling, which is applied to tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of large tunnel burial depth, complete water drainage, and mud and water inrush in water-conducting faults.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

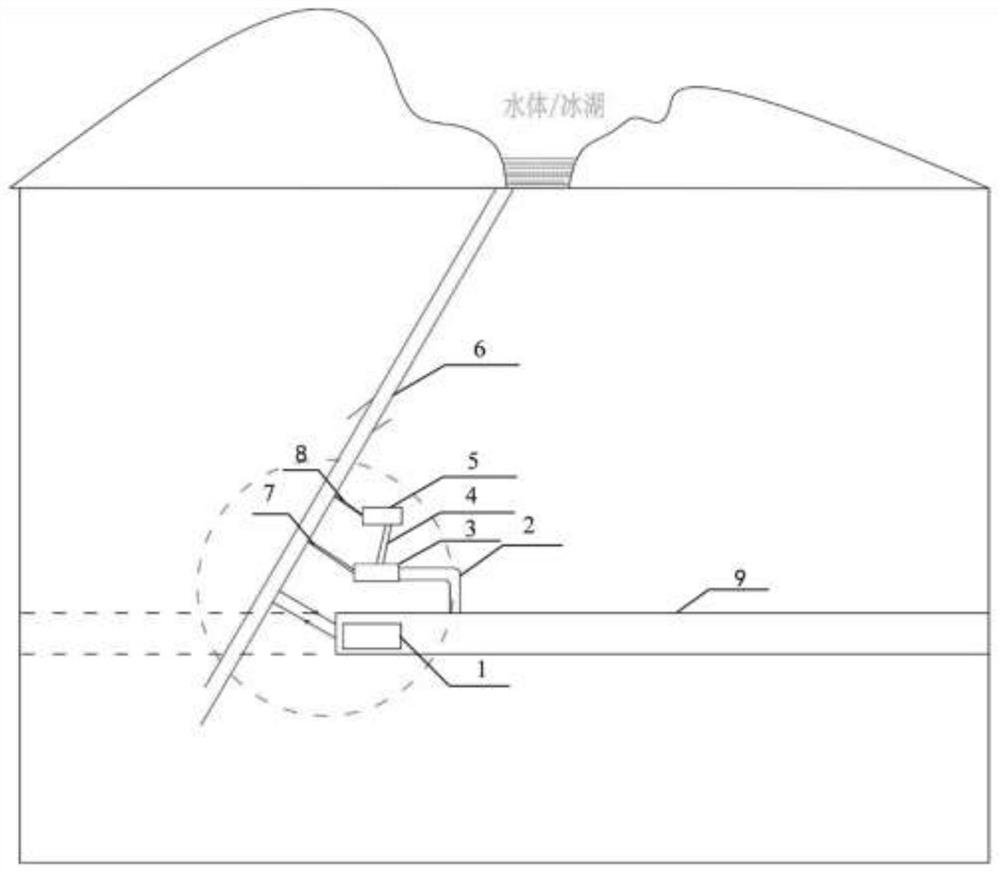

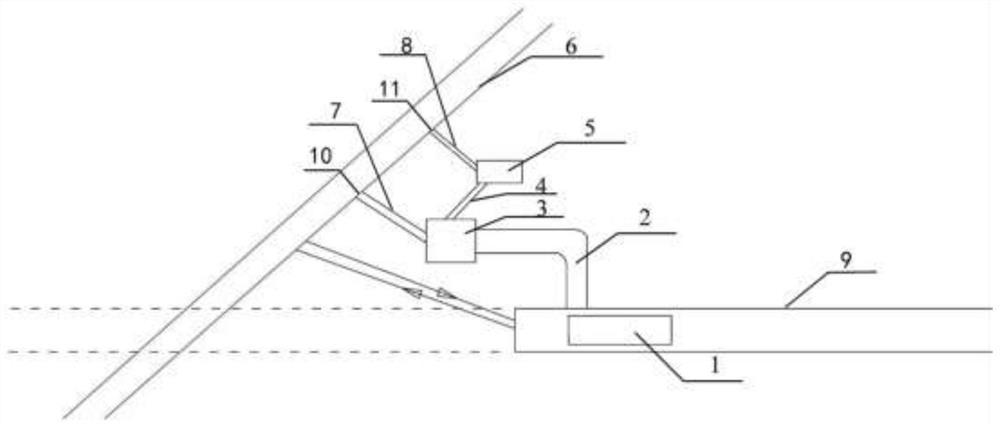

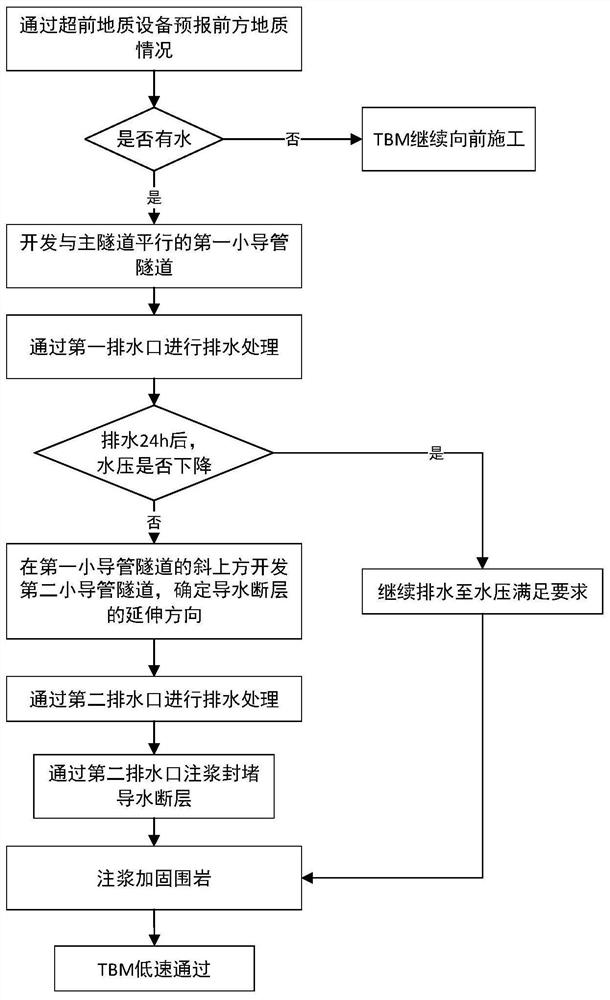

[0022] Example of tunnel construction method:

[0023] The main idea of the present invention is that, in order to control the water-conducting faults during tunnel construction, the present invention strictly implements the construction sequence of "exploration must be carried out when there is excavation, and excavation first and then excavation" in the TBM construction process: first, after detecting the presence of water, in the main tunnel The first small conduit tunnel is developed nearby, and the first drainage outlet is used for drainage operation. It is determined whether a water-conducting fault is encountered through the drainage situation; secondly, after encountering a water-conducting fault, a second small conduit tunnel is developed above the first small conduit tunnel , carry out the drainage operation through the second outfall; then carry out grouting through the second outfall, and seal the water-conducting fault between the first outfall and the second out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com