Rapid construction smooth blasting method for half-section micro-step

A technology of smooth blasting and micro-steps, which is applied in blasting, drilling equipment and methods, earthwork drilling and mining, etc. It can solve problems such as the reduction of rock strength and elastic modulus, the damage of retained rock mass, and the increase in construction costs, so as to reduce the Effects of vibration and damage, reduction of over- and under-excavation degree, and construction cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

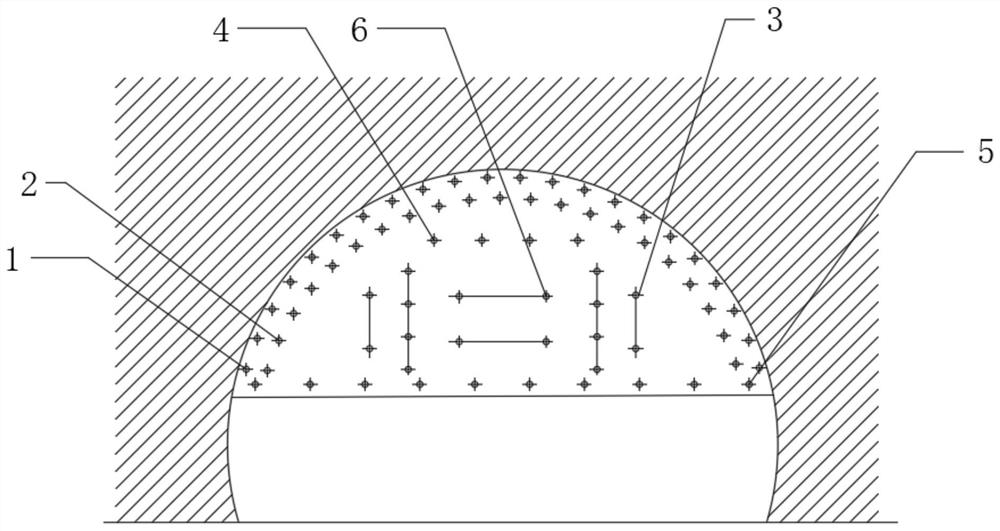

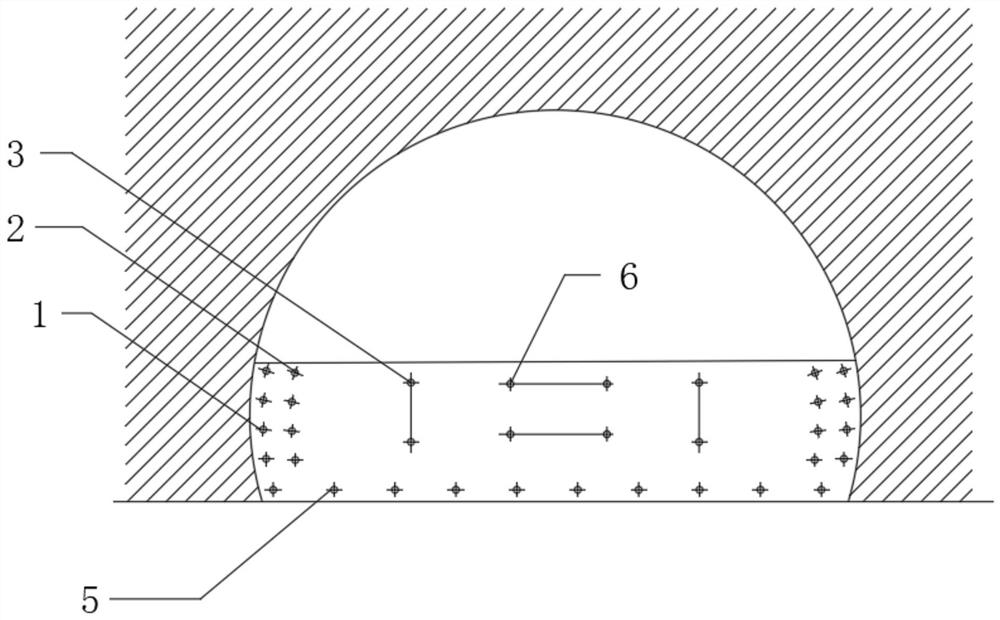

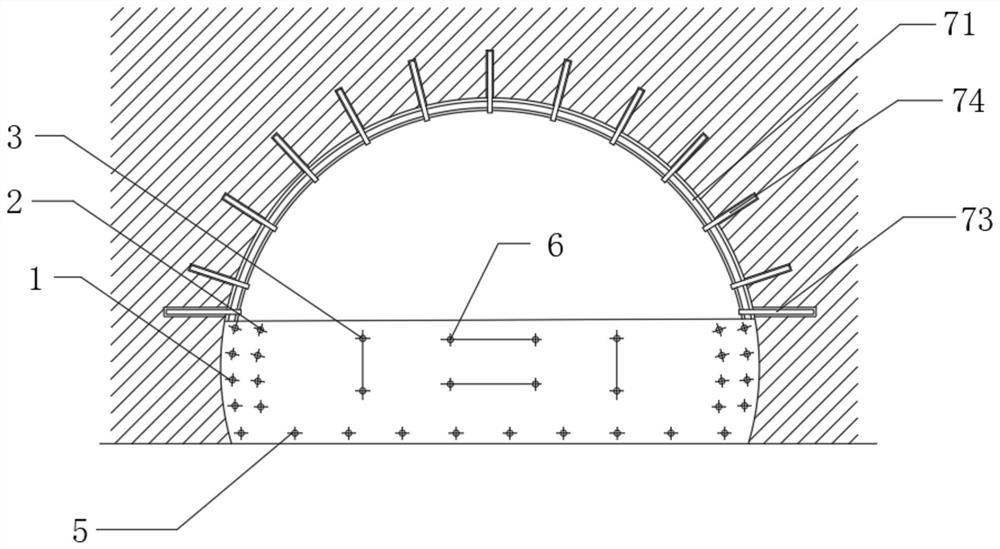

[0054] see Figure 1-6 , a half-section micro-step rapid construction smooth blasting method, a half-section micro-step rapid construction smooth blasting method, the method comprises the following steps:

[0055] Step 1): The construction personnel formulate an excavation plan according to the surrounding rock conditions. Under weak surrounding rock conditions, the half-section micro-step method is generally used for excavation; if the surrounding rock is too weak, the rock mass is extremely weathered, broken, and loose , the arch part can be opened first, that is, the arch part is excavated by blasting and supported, and then the lower half section is excavated and supported;

[0056] Step 2): Use the excavation and drilling trolley to set up peripheral eyeholes 1 and auxiliary eyeholes 2. The circumferential spacing of the peripheral eyeholes 1 is 40cm, and the distance between the peripheral eyeholes 1 and the auxiliary eyeholes 2 is 40cm. The circumferential distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com