Shielding spiral conveyor hydraulic system with proportional feedback control and accumulator oil supplementary

A shield screw and hydraulic system technology, applied in the direction of fluid pressure actuation system safety, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of difficult construction quality assurance, complex original stress, etc., to reduce surface deformation, High system reliability and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

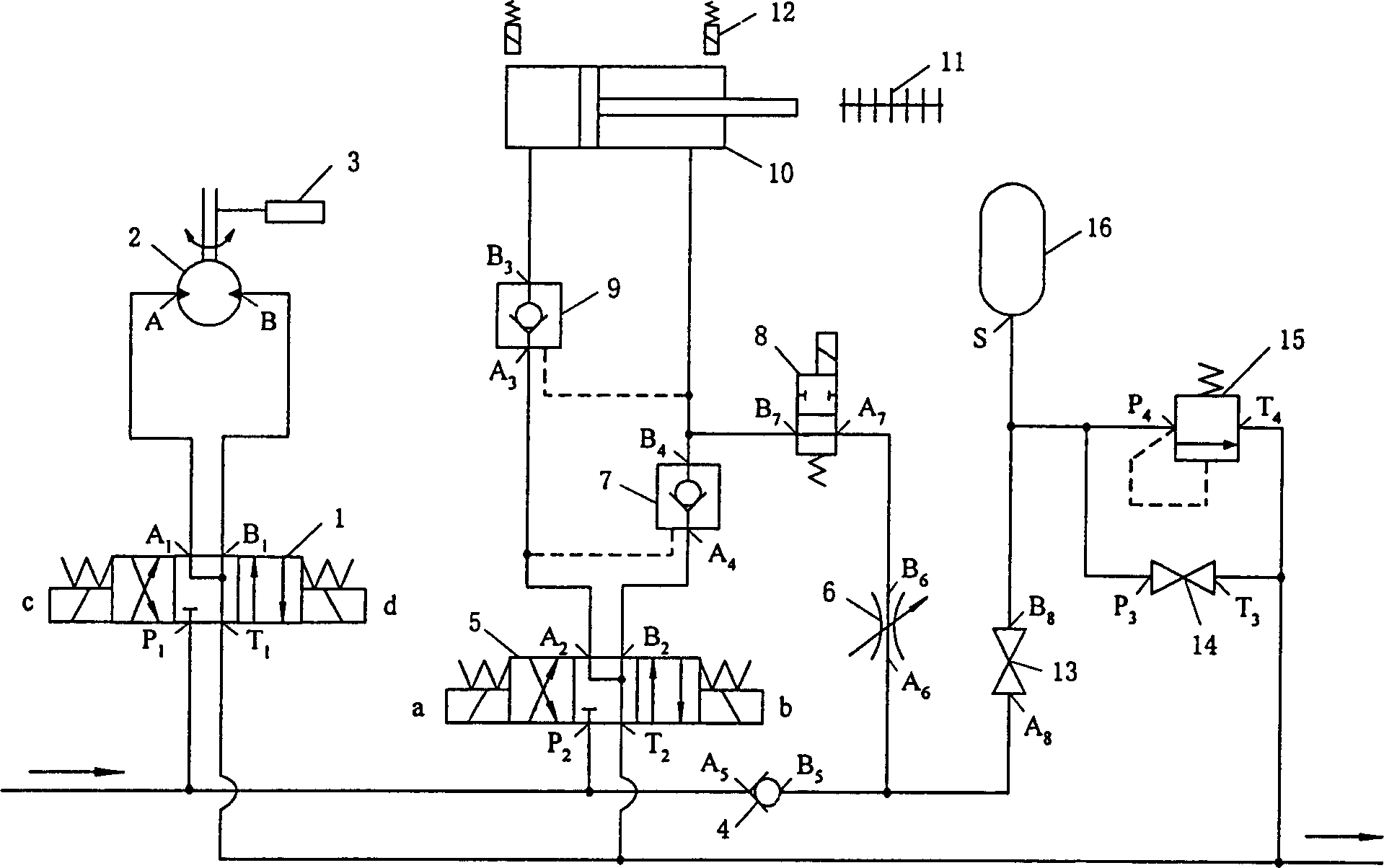

[0014] As shown in the drawings, the present invention includes two three-position four-way electromagnetic reversing valves 1, 5, a motor 2, a rotational speed sensor 3, a one-way valve 4, a throttle valve 6, and two hydraulically controlled one-way valves 7, 9 , Two-position two-way electromagnetic reversing valve 8, hydraulic cylinder 10, displacement sensor 11, travel switch 12, globe valve 13, unloading ball valve 14, overflow valve 15, accumulator 16. Oil inlet P of the first three-position four-way electromagnetic reversing valve 1 1 Respectively with the oil inlet P of the second three-position four-way electromagnetic reversing valve 5 2 , Oil inlet A of check valve 4 5 Connected; the oil return port T of the first three-position four-way electromagnetic reversing valve 1 1 Respectively with the oil return port T of the second three-position four-way electromagnetic reversing valve 5 2 , Oil return port T of unloading ball valve 14 3 , Oil return port T of relief ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com