Gasoline engine double-air-inlet large variable valve timing electric adjusting mechanism and control method thereof

A technology of valve phasing and adjustment mechanism, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problem of reducing the total opening time of the intake valve, reducing the angle of delayed valve closing, and limited improvement of intake efficiency, etc. problems, to achieve the effect of reducing cost and control complexity, reducing downlink resistance and power consumption, and high effective power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

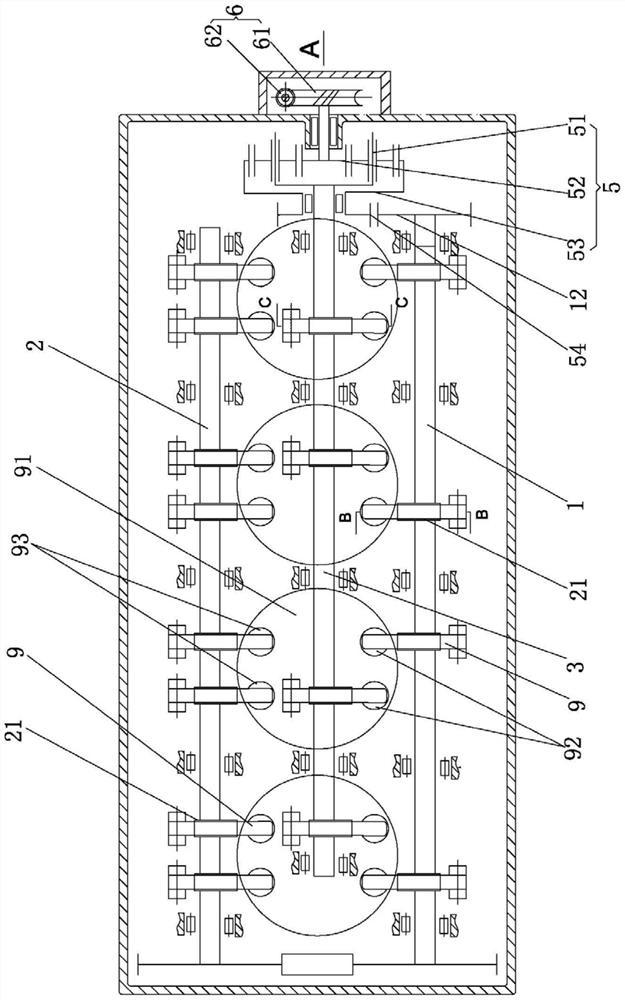

[0069] Example 1: Assuming that the sun gear has 52 teeth number Z 3 =20, planetary gear 51 parameter Z 4 =18, then the number of teeth of the cylindrical gear 12 and the external ring gear 54 is desirable: Z 1 = 38, Z 2 =18+10=28, or Z 1 =19,Z 2 =14.

Example

[0070] Example 2: Assuming that the sun gear has 52 teeth number Z 3 =20, planetary gear 51 parameter Z 4 =16, then the number of teeth of the cylindrical gear 12 and the external ring gear 54 is desirable: Z 1 =36,Z 2 =16+10=26, or Z 1 =18, Z 2 =13.

[0071] 2) Transmission ratio i of the phase (rotation angle) between the worm 62 and the intake camshaft II2 涡.H The transmission ratio of sun gear 52 and planet carrier 53 is (outer gear is stationary):

[0072] i H.3 =2(z 3 +z 4 ) / z 3

[0073] Let the gear ratio of the worm gear be: i 涡

[0074] there is i 涡.H = i 涡 i H.3 .

[0075] 3) Phase adjustment method

[0076] Assuming that the intake camshaft II2 phase advance angle needs to be adjusted to θ°, then according to the design transmission ratio, the rotation angle command value of the stepper motor is:

[0077] δ 电机 = i 涡H θ°.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap