Photovoltaic support main shaft structure and photovoltaic tracking support system comprising same

A photovoltaic support and spindle technology, applied in the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of increased hoop cost, low installation efficiency, and cumbersome installation, so as to save costs, improve assembly efficiency, and speed up The effect of installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

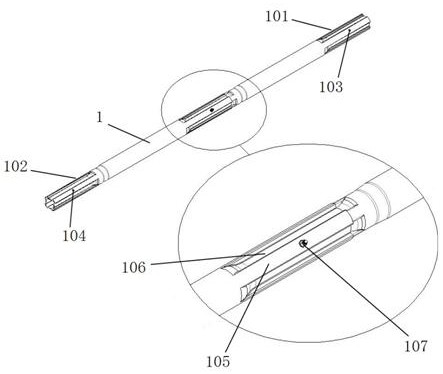

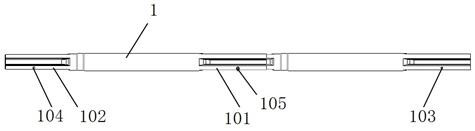

[0031] see Figure 1-6 As shown, this embodiment is a main shaft structure of a photovoltaic support, including a main shaft. There is a shrink tube end 102 embedded in it. The respective ports of the outer shrink tube end 101 and the inner shrink tube end 102 include axial protrusions 105 and axial recesses 106 alternately distributed along the circumferential direction, and the axial recesses 106 of the outer shrink tube end 101 and the inner shrink tube end 102 and The axial convex part 105 is radially positioned by means of loose fit, and the lock of the main shaft is achieved through the fit.

[0032] In this embodiment, the outer shrink tube end 101 is provided with an outer positioning hole 103, and the inner shrink tube end 102 is correspondingly provided with an inner positioning hole 104. The fasteners 107 in the positioning holes 103 and the inner positioning holes 104 are fixed, and the fasteners can be tightened nuts.

[0033] In this embodiment, the outer posi...

Embodiment 2

[0038] The structure and application of this embodiment are basically the same as those of Embodiment 1, the difference is that the outer positioning hole 103 is located on the axial recess 106 of the outer shrink tube end 101, and the inner positioning hole 104 is located on the inner shrink tube On the axial recess 106 of the end 102.

Embodiment 3

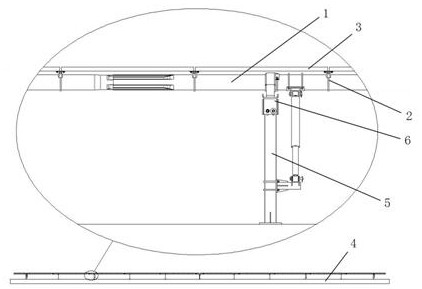

[0040] This embodiment is a photovoltaic tracking support system, which includes a base 4, a column 5, a first purlin assembly 6, a second purlin assembly 2, a photovoltaic module panel 3 and the photovoltaic support as described in the first embodiment Spindle structure. The main shaft 1 of the photovoltaic support main shaft structure is fixedly supported by the photovoltaic module panel 3 through the second purlin assembly 2 , and the base 4 provides rotational support for the main shaft through the column 5 and the first purlin assembly 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com