Guide spray pipe of rotary detonation combustion chamber

A combustion chamber and nozzle technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., to achieve the effect of improving the overall propulsion performance, stabilizing the flight attitude, and eliminating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

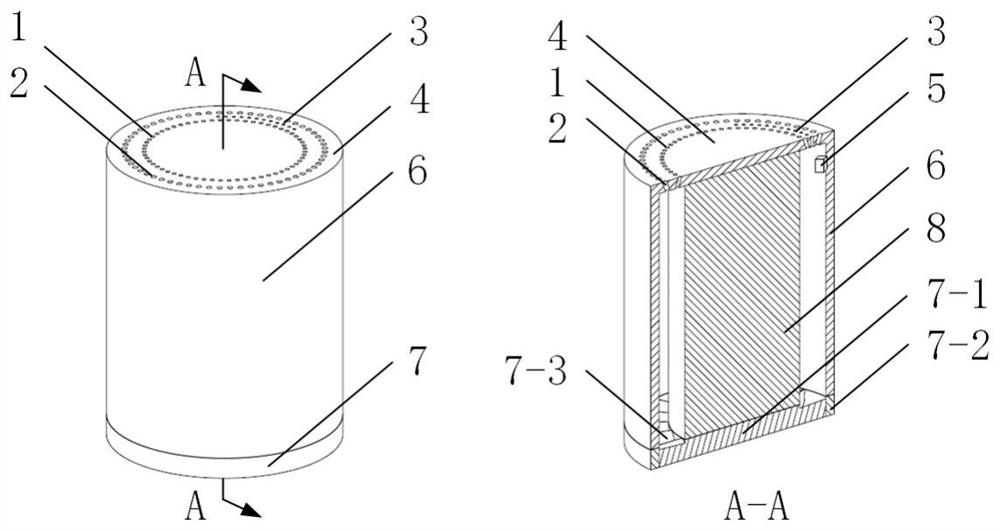

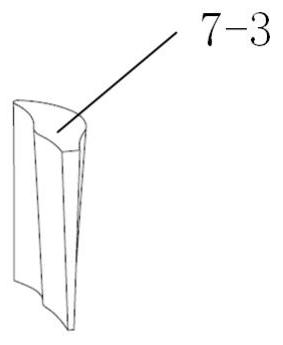

[0053] see figure 1 , In this example, an annular combustion chamber is adopted, the outer ring 7-2 of the guide nozzle is directly connected with the outer ring 6 of the combustion chamber, and the center body of the guide nozzle 7-1 is connected with the inner column 8 of the combustion chamber. Because the width of the combustion chamber is relatively small, the angles of the outside and the inner outlet airflow of the guide nozzle 7 inlet are similar, so straight guide nozzle blades 7-3 can be used (see figure 2 and image 3 ), which deflects the circumferential speed of the airflow to the axial speed, and continues to expand and accelerate until it is discharged along the axial direction, so as to improve the overall propulsion performance, and at the same time, it can eliminate the torque originally generated by the outlet swirl and stabilize the flight attitude of the aircraft.

Embodiment 2

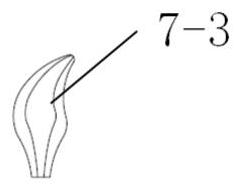

[0055] see Figure 4 , In this example, an empty barrel combustion chamber is used, and the outer ring 7-2 of the guide nozzle is directly connected with the outer ring 6 of the combustion chamber. Because the combustion chamber has no inner column, the overall vane height of the guide vane 7-3 is relatively large, and the center body 7-1 of the guide nozzle and the outer ring 7-2 of the guide nozzle are used to fix the guide vane 7-3. The outside of the guide nozzle 7 inlet and the inboard outlet airflow angle differ greatly, and the twist guide nozzle blade 7-3 can be used (referring to Figure 4 and Figure 5 ), which deflects the circumferential speed of the airflow to the axial speed, and continues to expand and accelerate until it is discharged along the axial direction, so as to improve the overall propulsion performance, and at the same time, it can eliminate the torque originally generated by the outlet swirl and stabilize the flight attitude of the aircraft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com