A continuously rotating detonation combustion chamber and ramjet

A technology of combustion chamber and detonation, which is applied in the field of ramjet engine, can solve the problems of limited working boundary of circular combustion chamber, large thermal protection area and difficulty, low average pressure of combustion chamber, etc., so as to widen the working boundary of equivalent ratio and optimize Thrust performance and low flow loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

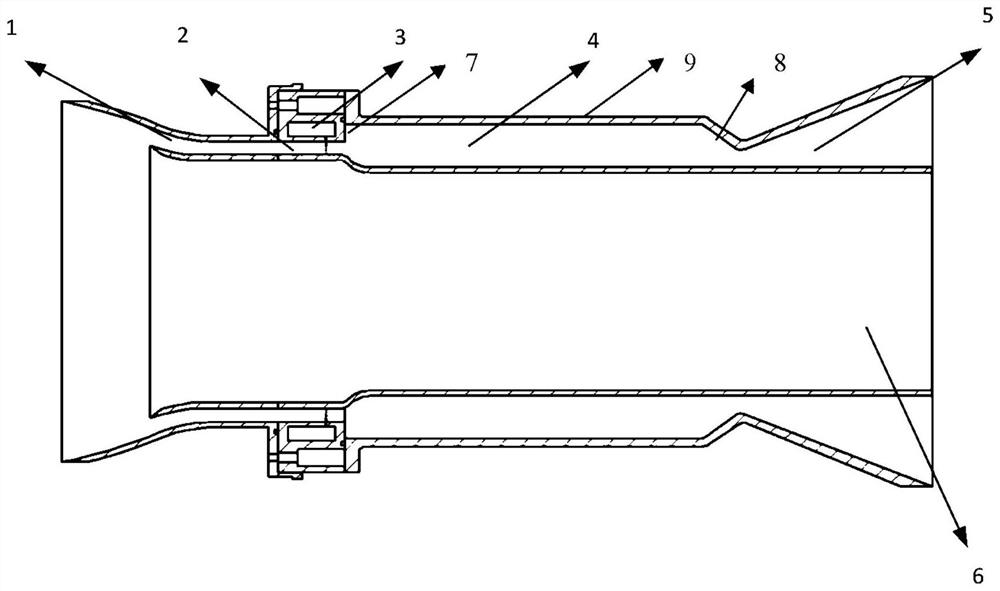

[0029] refer to figure 1 , in an embodiment of the present invention, a continuous rotating detonation combustion chamber is provided, which includes an outer casing 9 and a cylinder 6 located in the inner cavity of the outer casing 9. An annular flow channel is formed between them, the front end of the annular flow channel is set as the intake channel 1, and the annular flow channel after the intake channel 1 is sequentially provided with an isolation section 2, a detonation combustion chamber 4 and a tail nozzle 5. The connection between the detonation combustion chambers 4 is a stepped sudden expansion transition, forming a backward step 7, which can stabilize the flame and enhance combustion; the annular flow passage in the rear section of the detonation combustion chamber is linearly reduced to form an inclined transition connecting the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com