Fiber grating humidity sensor and manufacturing method thereof

A technology of humidity sensor and optical fiber grating, which is applied in the direction of instruments, thermometers, scientific instruments, etc., can solve problems such as waste, influence of humidity-sensitive characteristics, and degradation of surface coating performance, and achieve the effects of easy replacement and guaranteed coating quality

Pending Publication Date: 2021-07-23

AIR FORCE ENG UNIV OF PLA AIRCRAFT MAINTENACE MANAGEMENT SERGEANT SCHOOL

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Because the fiber grating sensor has the advantages of strong anti-electromagnetic interference, good flexibility, corrosion resistance, light weight, etc., it can overcome many shortcomings of the traditional humidity sensor, so it has been well developed. The existing fiber grating sensors are based on it The humidity-sensitive material is covered to monitor the relative humidity. However, after a long period of repeated use, the moisture-sensitive material layer will be deteriorated or worn due to factors such as environmental corrosion, and its humidity-sensitive characteristics will be affected. The existing practice is Directly replace the new sensor and throw away the old one. However, the replaced fiber optic SPR probe is good, only the deterioration or wear of the surface coating leads to a decline in performance, and direct throwing away causes a certain amount of waste.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

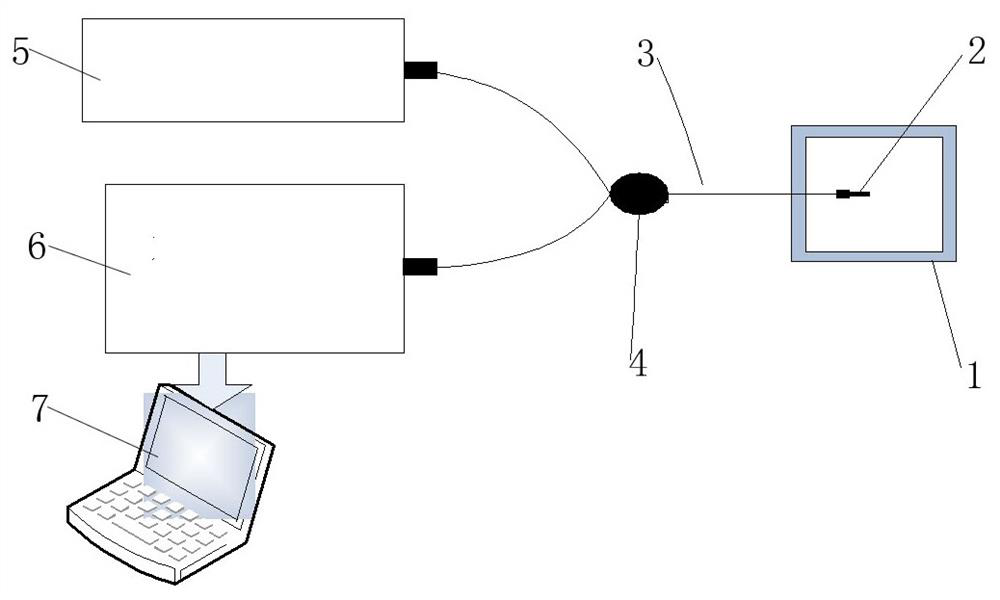

[0032] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 . In the figure, 1-adjustable humidity chamber, 2-optical fiber SPR probe, 3-multimode optical fiber, 4-Y-type optical fiber coupler, 5-broadband light source, 6-optical fiber spectrum demodulator, 7-PC.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

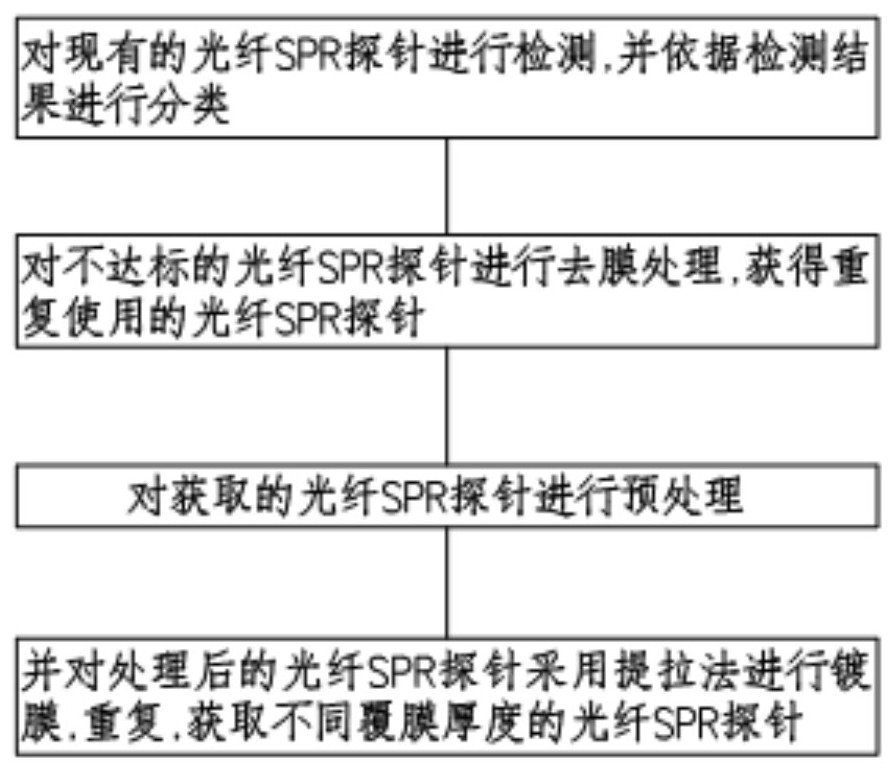

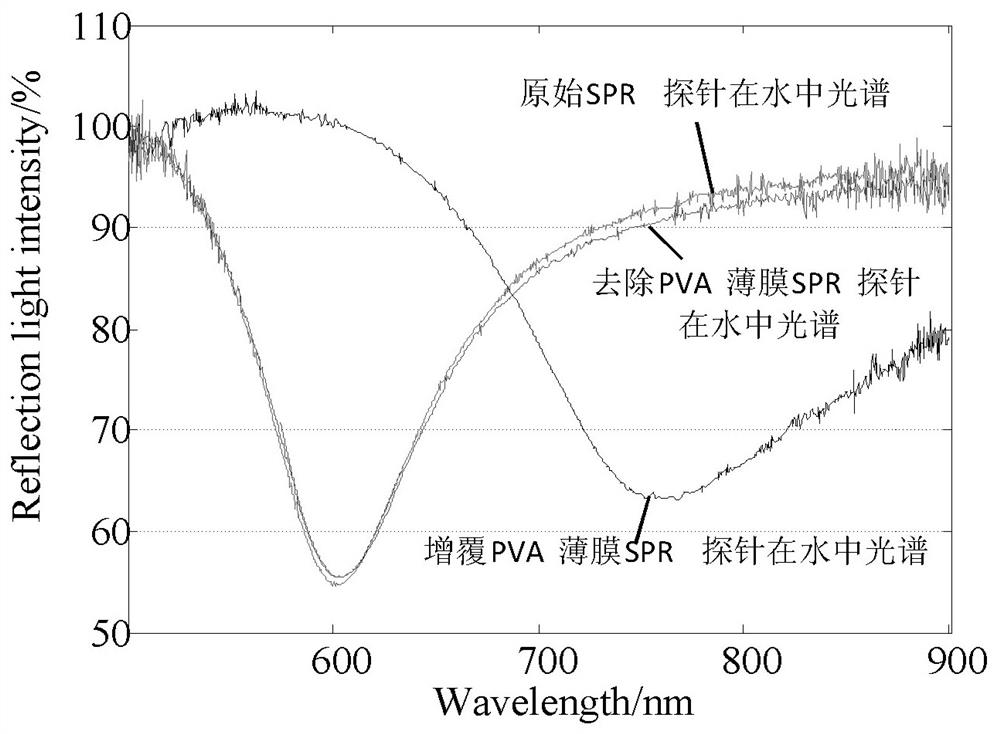

The invention discloses a fiber bragg grating humidity sensor. A manufacturing method of the sensor comprises the steps of detecting an existing optical fiber SPR probe and classifying according to a detection result; carrying out film removal treatment on a substandard optical fiber SPR probe to obtain a reusable optical fiber SPR probe; carrying out pretreatment on the obtained optical fiber SPR probe; and coating the treated optical fiber SPR probe with a coating film by adopting a pulling method, and repeating to obtain optical fiber SPR probes with different coating film thicknesses. According to the method, the optical fiber SPR probe with intact performance is obtained by carrying out reversible treatment on the optical fiber SPR probe with coating failure, the optical fiber SPR probe is coated again, effective optical fiber SPR probes with different coating thicknesses are obtained, and the method has the functions of waste utilization and resource saving.

Description

Technical field: [0001] The invention relates to a temperature sensor, in particular to a fiber grating humidity sensor. Background technique: [0002] Because the fiber grating sensor has the advantages of strong anti-electromagnetic interference, good flexibility, corrosion resistance, light weight, etc., it can overcome many shortcomings of the traditional humidity sensor, so it has been well developed. The existing fiber grating sensors are based on it The humidity-sensitive material is covered to monitor the relative humidity. However, after a long period of repeated use, the moisture-sensitive material layer will be deteriorated or worn due to factors such as environmental corrosion, and its humidity-sensitive characteristics will be affected. The existing practice is Directly replace the new sensor and throw away the old one. However, the replaced fiber optic SPR probe is good, only the deterioration or wear of the surface coating leads to a decline in performance, an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01K11/3206

CPCG01K11/3206

Inventor 高涛黄旌韩梅杨钰郭辉陈璞李猛郭娟

Owner AIR FORCE ENG UNIV OF PLA AIRCRAFT MAINTENACE MANAGEMENT SERGEANT SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com