Preparation method of nano flaky calcium sulfate;

A nano-flaky, calcium sulfate technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of no nano-scale flake calcium sulfate preparation method, high energy consumption, etc., achieve enhanced reflection and refraction effects, and rich sources , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of nano-flaky calcium sulfate, the steps are as follows:

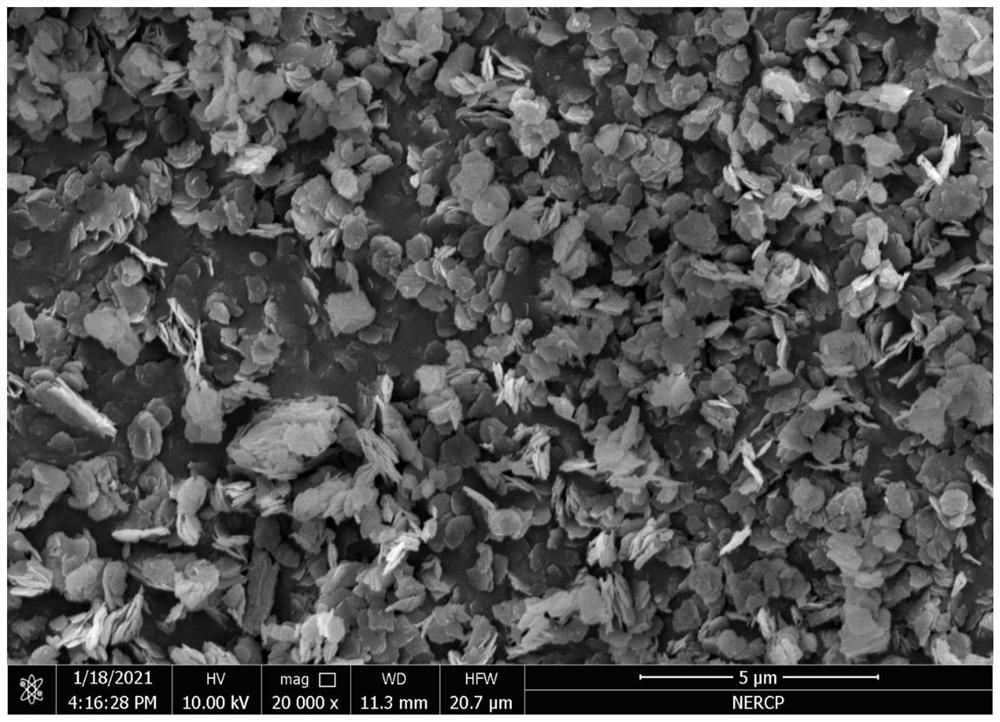

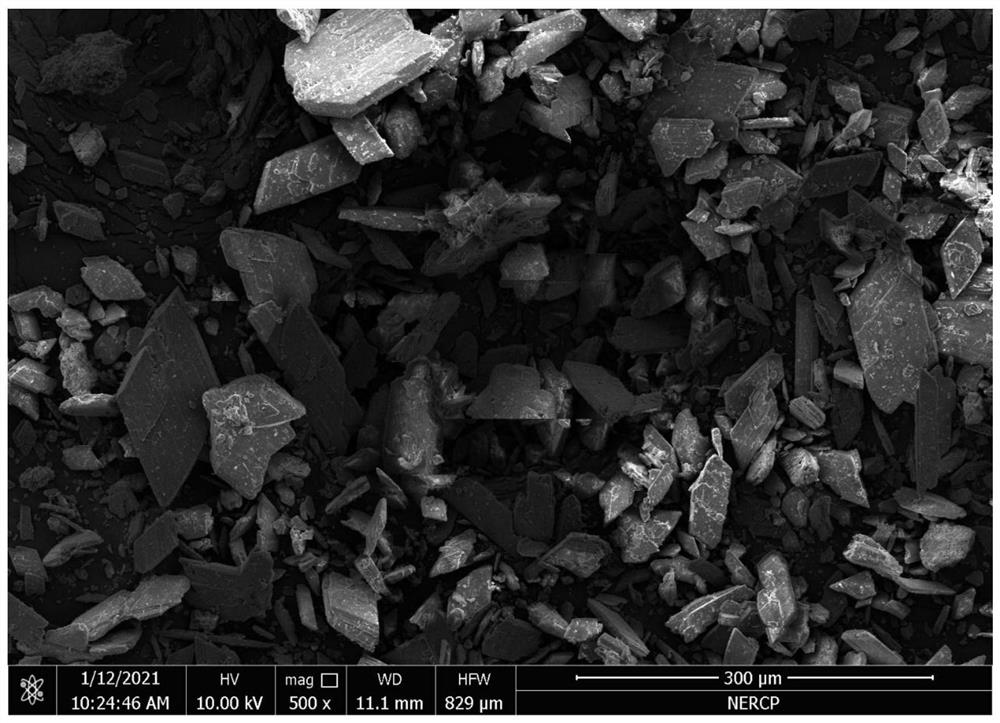

[0027] (1) Take a certain amount of phosphogypsum in a large beaker, add tap water and stir, pour off the upper layer of water after standing still, then add water to stir, filter, and dry at 60°C to obtain water-washed phosphogypsum, microscopic appearance of water-washed phosphogypsum See attached for elemental composition image 3 And attached Figure 4 .

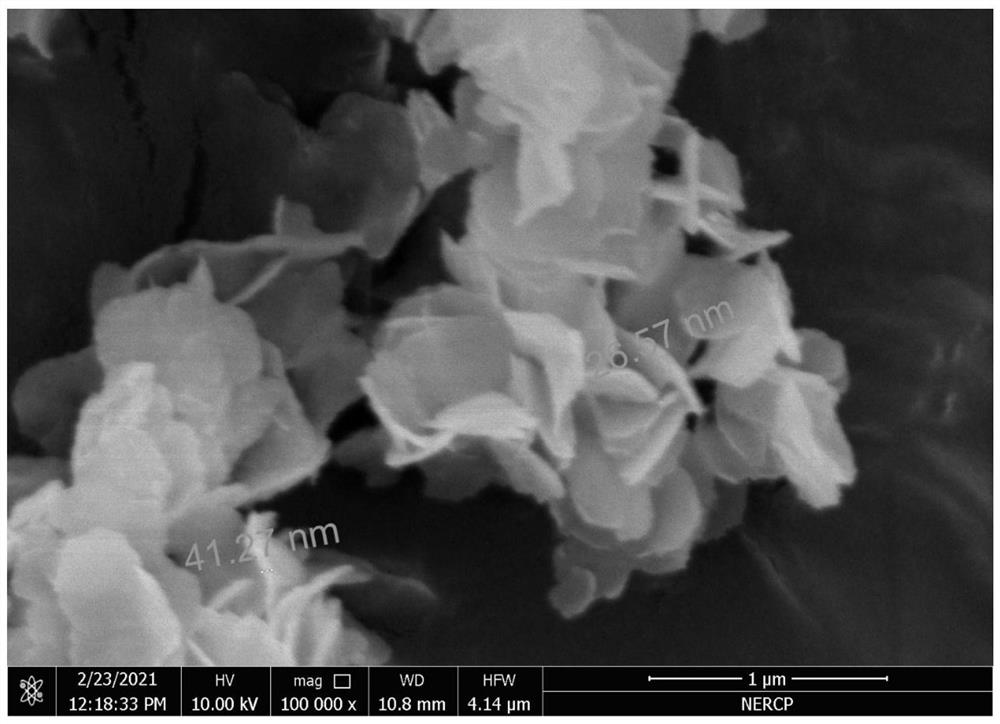

[0028] (2) Add 60 mL of glycerol and 30 mL of ethylene glycol into a three-necked flask, stir at a constant temperature of 80°C for 10 minutes, add 22 mmol of disodium edetate and stir until the solution is transparent, adjust the temperature to 98°C, add 10 g of water-washed phosphogypsum, and Centrifuge immediately after stirring for 3 hours, pour off the supernatant, add boiling water, stir, centrifuge and dry at a constant temperature of 60°C to obtain nano-flaky calcium sulfate. figure 1 And attached fig...

Embodiment 2

[0029] Embodiment 2: a kind of preparation method of nano-flaky calcium sulfate, the steps are as follows:

[0030] Add 90mL of ethylene glycol, add 7mmol of diethylenetriaminepentacarboxylic acid, stir at 110°C for 30min until transparent, add 20g of calcium sulfate dihydrate, react for 6h, centrifuge while hot, add ethanol, stir and ultrasonically centrifuge, dry at 200°C to obtain nano-flaky sulfuric acid calcium.

Embodiment 3

[0031] Embodiment 3: a kind of preparation method of nano-flaky calcium sulfate, the steps are as follows:

[0032] Add 30 mL of glycerol and 60 mL of ethylene glycol into a three-necked flask, stir at 85°C for 10 minutes, add 11 mmol of disodium ethylenediaminetetraacetate and stir until the solution is transparent, add 10 g of water-washed phosphogypsum, stir at constant temperature for 4 hours, then centrifuge immediately, add ethanol and stir Ultrasonic cleaning and centrifugation, and drying at 400 °C to obtain nano-flaky calcium sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com