Industrial detonating cord flux core prepared from energetic material by-product

A detonating cord and by-product technology, applied in the field of industrial detonating cord cores and industrial detonating cords, can solve the problems of high price of detonating cords and high cost of detonating cords, achieve low cost and improve dispersion the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

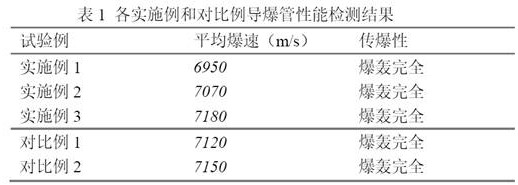

Embodiment 1

[0016] Put 92% of PETN by-products and 8% of graphite powder into the mixing drum (ball-to-material ratio 3:1) and rotate for 60 minutes. Grind and mix evenly to prepare the detonating cord core. Dosing at 11.5±0.5g / m It is used in cable making machines and extruders to form industrial detonating cords. The industrial detonating cord complies with the performance index of GB / 9786-1999 "Ordinary Detonating Cord".

Embodiment 2

[0018] Add 95% PETN by-products and 5% graphite powder to the mixing drum (ball-to-material ratio 3:1) and rotate for 60 minutes, grind and mix evenly to prepare the detonating cord core. It is used in cable making machines and extruders to form industrial detonating cords. The industrial detonating cord complies with the performance index of GB / 9786-1999 "Ordinary Detonating Cord".

Embodiment 3

[0020] Put 98% PETN by-products and 2% graphite powder into the mixing drum (ball-to-material ratio 3:1) and rotate and mix for 60 minutes, grind and mix evenly to prepare the detonating cord core, with a dosage of 11.5±0.5g / m It is used in cable making machines and extruders to form industrial detonating cords. The industrial detonating cord complies with the performance index of GB / 9786-1999 "Ordinary Detonating Cord".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com