Quasi-static in situ biaxial tensile mechanical properties testing device under scanning electron microscope

A technology of biaxial stretching and scanning electron microscopy, which can be used in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc. It can solve the problems of high observation synchronization requirements, insufficient magnification, and high imaging resolution. , to achieve the effect of convenient in-situ observation, compact structure and high transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following in conjunction with the accompanying drawings further illustrates the details of the present invention and a particular embodiment thereof.

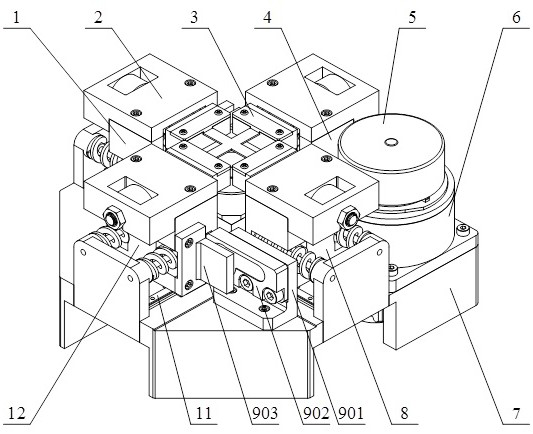

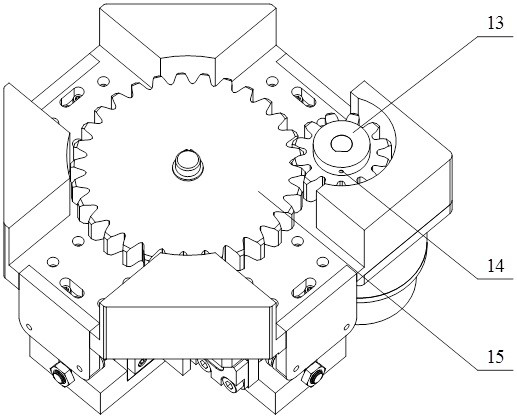

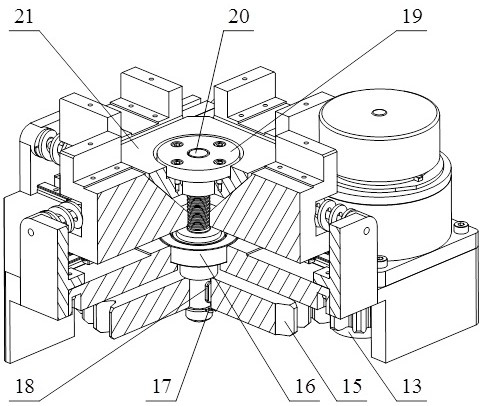

[0024] See Figures 1 through 6As shown, the quasi-static in situ biaxial tensile mechanical performance test apparatus under the scanning electron microscope of the present invention, mainly including power and transmission components, wedge transmission components, clamping components 3, support platform 7 and detection components; The power and transmission assembly adopts a DC servo motor 5 as the power source, driven by the gearbox 6 deceleration drive lead screw shaft 20, lead screw shaft 20 through the lead screw nut 19 and the wedge block 21 connection, the DC servo motor 5 output of the rotary motion into a linear motion of the wedge 21; The wedge transmission assembly in the wedge block 21 and the carriage 101 through a 45-degree inclined contact transmission, to achieve the precise synchronous movement of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com