Numerical simulation calculation method for multi-layer and multi-pass welding process of header tube socket

A multi-layer multi-pass welding and welding process technology, which is applied in the field of welding numerical simulation, can solve problems such as stress concentration, high welding technical difficulty, and large weld thickness, and achieve rapid modeling and significant laying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

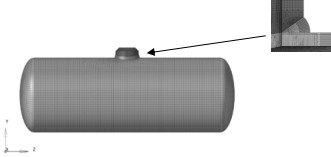

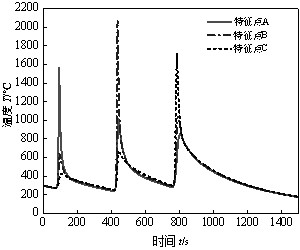

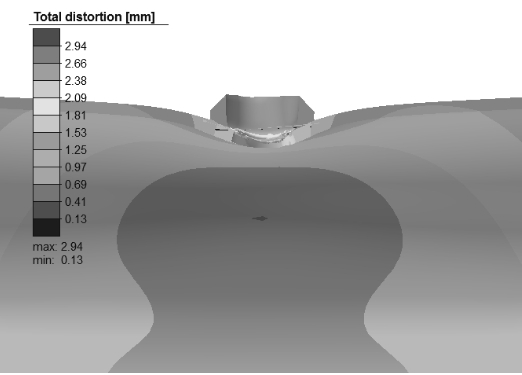

[0013] Such as figure 1 , figure 2 , image 3 As shown, a numerical simulation calculation method for the multi-layer multi-pass welding welding process of the header pipe seat shown in the present invention includes the following steps. Step S1: Establish a three-dimensional thermal-mechanical coupling calculation model of the pipe seat, header, and weld, and divide the solid model of the weldment of the header pipe seat into a finite element mesh to form several mesh units of the solid model. Step S2: Set the initial conditions and boundary conditions of the welding model. Step S3: Determine the heat source equation and welding parameters used for the saddle we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com