Method for solving stress of thin substrate

A thin substrate and stress technology, applied in the field of solving the thin substrate stress, can solve the problems of measurement value fluctuation, limited light wave penetration depth, lack of precision, etc., to reduce the large stress fluctuation and accurately evaluate the thin substrate processing technology. Quality, the effect of improving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

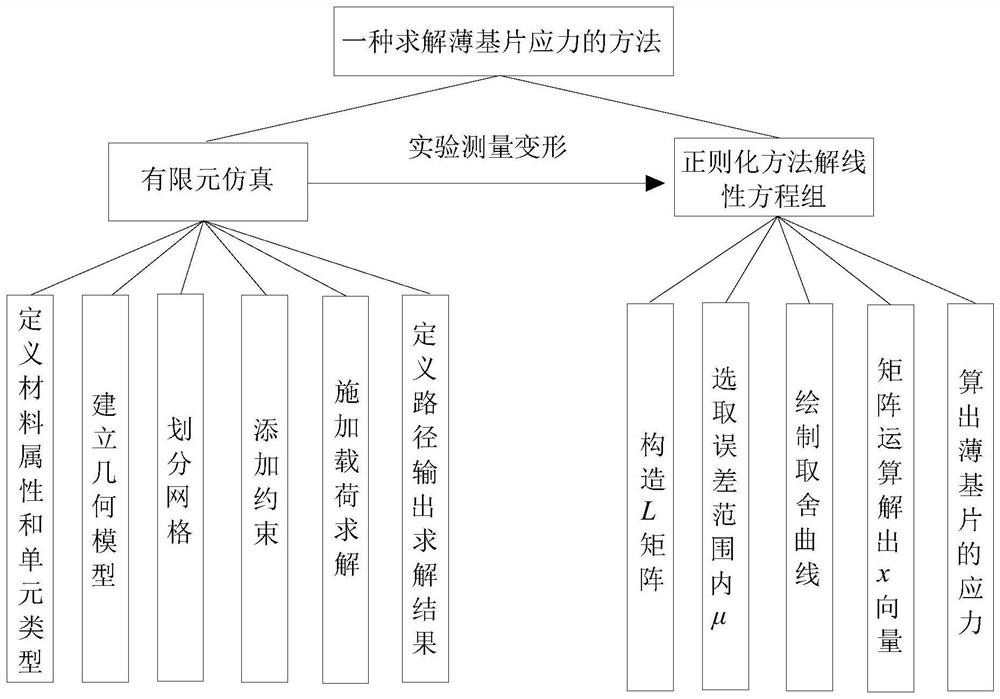

[0082] This embodiment provides a method for solving the stress of a thin substrate, such as figure 1 As shown, the technical solution can be summarized as two processes: finite element simulation and regularization method for solving linear equations.

[0083] The finite element simulation includes: defining material properties and element types, establishing geometric models, dividing meshes, adding constraints, applying loads to solve, and defining paths to output solution results. The regularization method to solve the linear equations includes: constructing an L matrix, selecting the penalty item coefficient μ of the regularization method, drawing a trade-off curve, matrix operation to solve the x vector, and calculating the relevant steps of the stress of the thin substrate.

[0084] In detail, the method provided in this embodiment includes the following steps:

[0085] S1: Obtain the basic parameters of the thin substrate to be analyzed for stress; the basic parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com