Non-photopolymerization PCB solder resist ink windowing and solder resist oil bridge process

A technology of solder resist ink and PCB board, which is applied in pattern and photolithography, coating of non-metallic protective layer, electrical components, etc., can solve the problem of low resolution of solder resist ink, inability to completely retain solder resist oil bridge, and impurity virtual soldering and other problems, to achieve the effect of solving poor welding and solving the problem of solder mask window deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention,

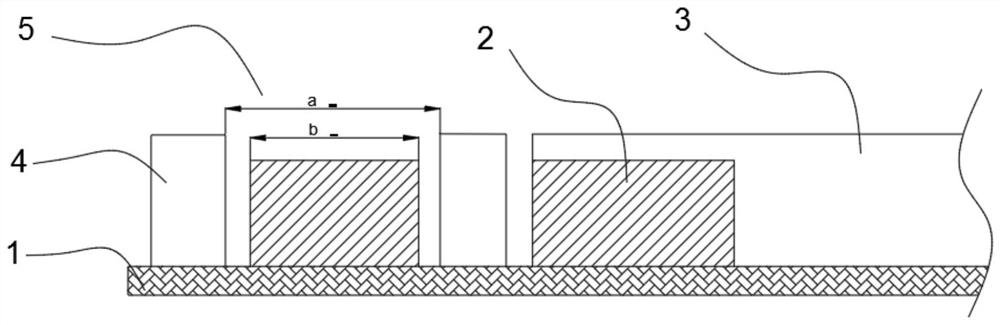

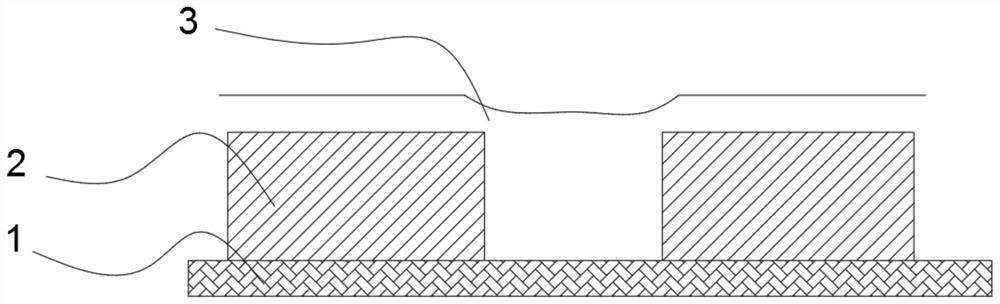

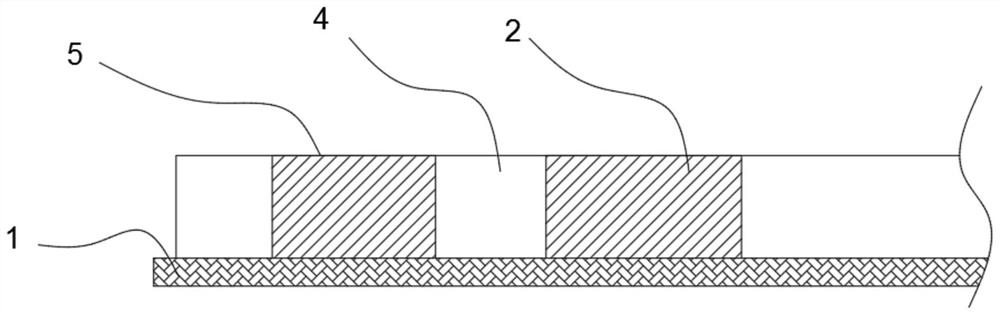

[0030] Please refer to Figure 2-4 ,

[0031] A non-photopolymerizable PCB solder resist ink window opening and solder resist oil bridge process, used for high-precision PCB micro pads 2 solder resist ink 3 window opening 5, solder resist oil bridge 4 production,

[0032] S1: Make the blocking screen

[0033] Choose a screen printing screen with a mesh size of 43T and a tension of 24N. According to the hole position information of the PCB board 1 to be produced, print the corresponding block film graphics on the screen (except for the holes that need to be plugged). clogged.

[0034] S2: Screen printing ink

[0035] Install the stencil with the stop point on the double scraper automatic screen printing machine, fix the PCB board 1 position according to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com