Side-channel compressor for a fuel cell system for conveying and/or compressing a gaseous medium

A fuel cell system, gaseous medium technology, applied to components of pumping devices for elastic fluids, liquid fuel engines, machines/engines, etc., can solve the problem of side channel compressors reducing delivery pressure, delivery pressure and low efficiency, Unfavorable flow relationship and other problems, to achieve the effect of reducing assembly trouble, error proneness, and reducing failure probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

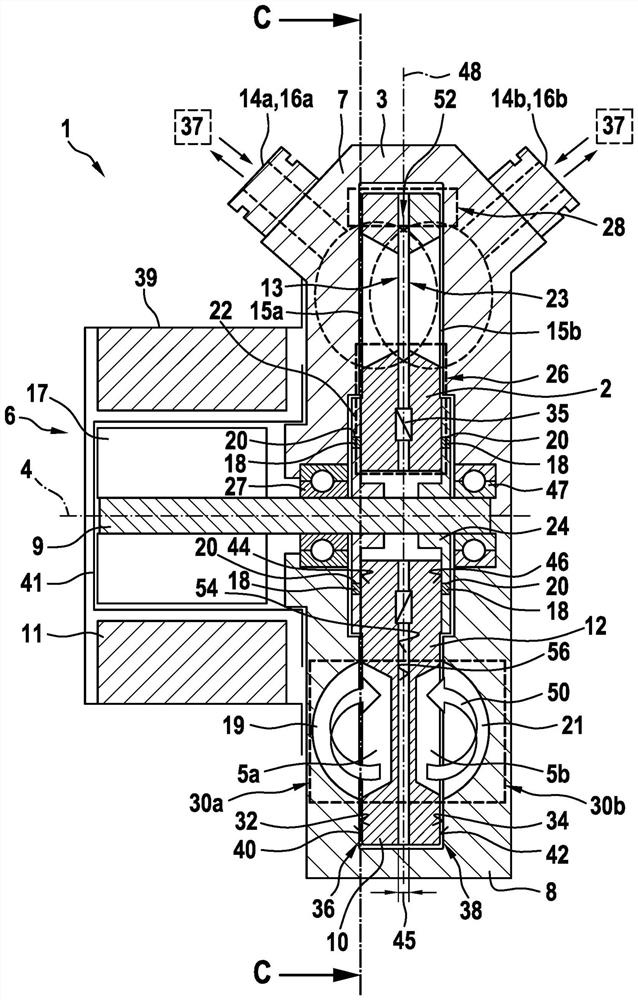

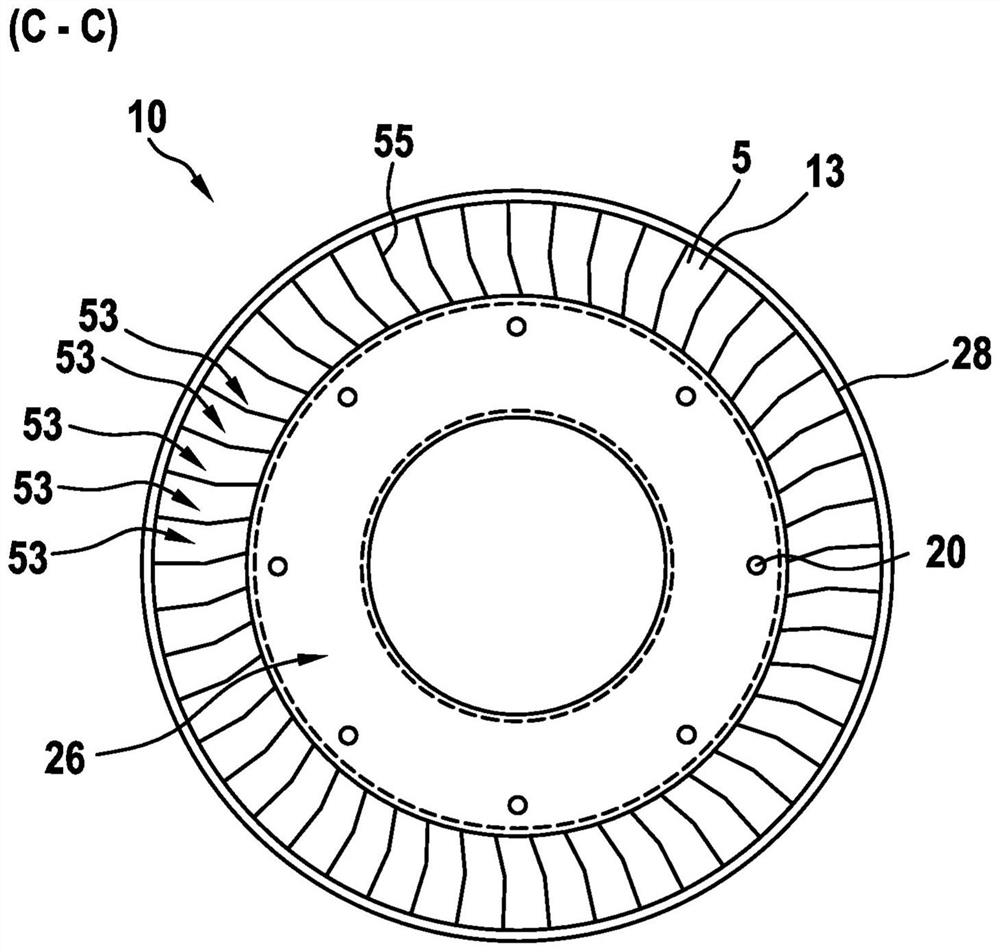

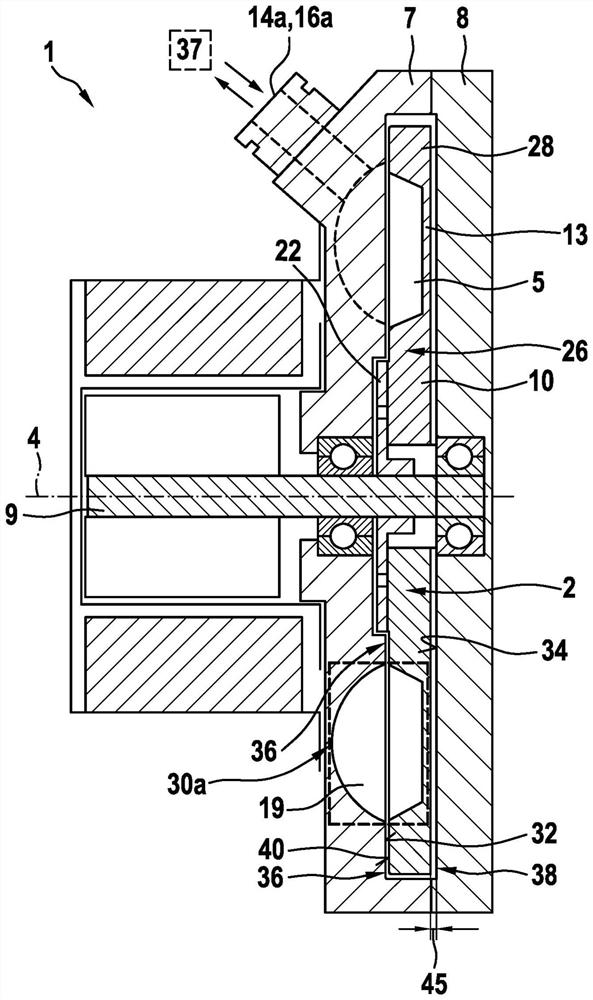

[0021] from according to figure 1 The illustration in FIG. 1 results in a schematic sectional view of a side channel compressor 1 according to the invention and a compressor wheel 2 according to the invention according to a first embodiment.

[0022] In this case, side channel compressor 1 is arranged in the anode circuit of fuel cell system 37 as a component, for example in addition to the ejector pump, and serves to convey and / or compress a gaseous medium, in particular hydrogen. In this case, the side channel compressor 1 has a housing 3 , with a compressor chamber 30 located in the housing 3 , which has at least one surrounding side channel 19 , 21 . Here, the compressor wheel 2 is located in the housing 3 , wherein the compressor wheel 2 is arranged rotatably about the axis of rotation 4 , and wherein the compressor wheel 2 has compression rings arranged on its circumference around the axis of rotation 4 . The delivery unit 5 in the area of the machine room 30 . The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com