Ionic semipermeable membrane module, electrolysis device and disinfectant manufacturing equipment

A semi-permeable membrane and ion technology, applied in the field of electrolysis device and disinfectant manufacturing equipment, ion semi-permeable membrane components, can solve the problems of potassium hydroxide solution and pure water cannot be fully electrolyzed, small area, etc., to improve the sterilization effect , the effect of prolonging the flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

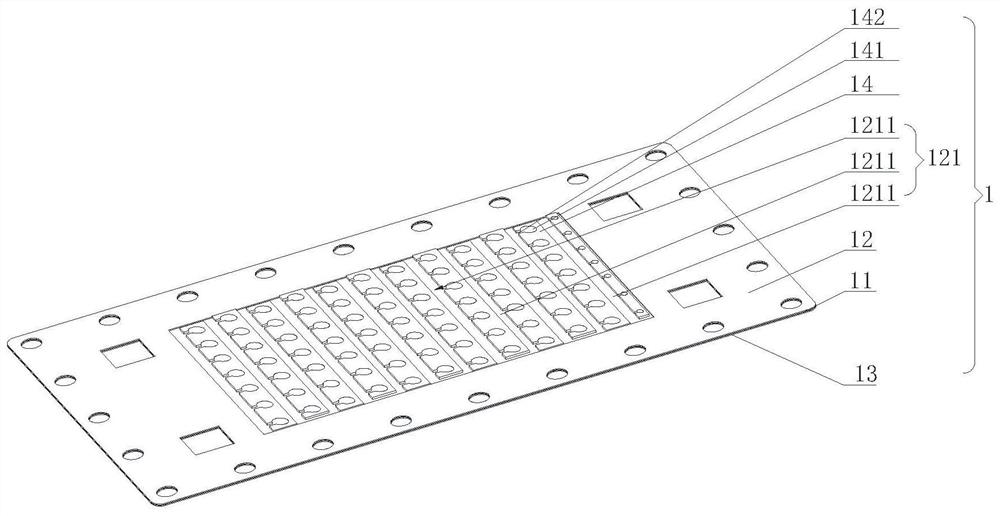

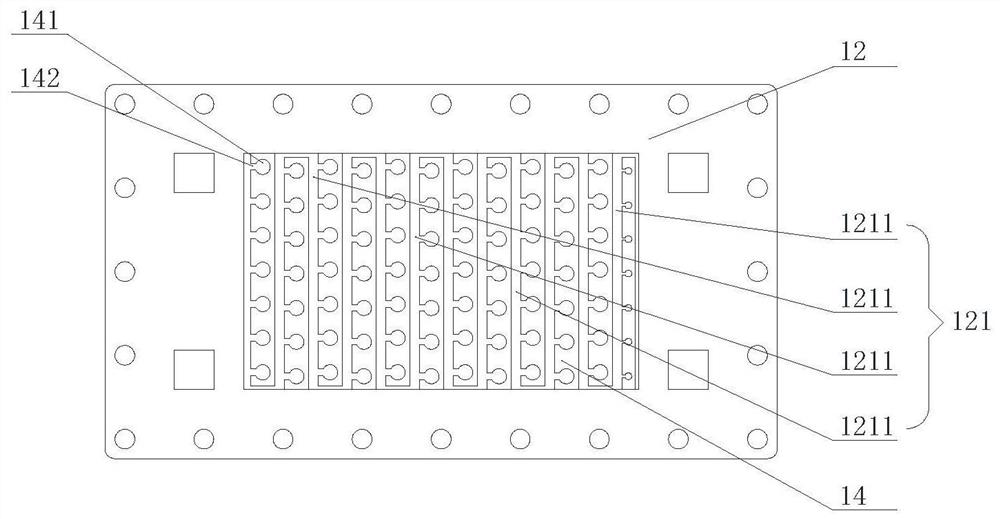

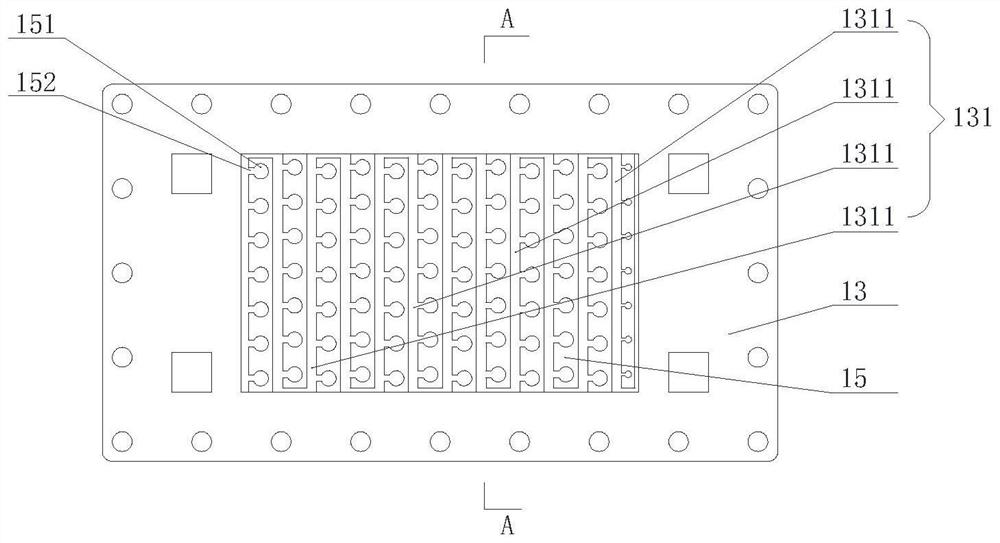

[0087] In order to solve the above problems, the embodiment of the present application provides an ion semi-permeable membrane module, such as Figure 1 to Figure 3 As shown, it includes: an ion semipermeable membrane 11 , a first pressing film frame 12 , a second pressing film frame 13 , a first mesh plate 14 and a second mesh plate 15 .

[0088] Among them, such as figure 2 , image 3 and Figure 4 As shown, the ion semipermeable membrane 11 has: a first surface 111 and a second surface 112 opposite to the first surface 111 . Moreover, the first pressing frame 12 presses against the first surface 111 of the ion semipermeable membrane 11 , and the second pressing frame 13 presses against the second surface 112 of the ion semipermeable membrane 11 . Simultaneously, the first pressure film frame 12 also has the anode chamber 121 that reveals the first surface 111 of the partial ion semipermeable membrane 11, and the second pressure film frame 13 also has the second surface ...

Embodiment approach 2

[0096] A second embodiment of the invention relates to an electrolysis device such as Figure 5 As shown, it includes: several positive electrode plate assemblies 2, several negative electrode plate assemblies 3, and several ion semipermeable membrane assemblies 1 as described in the first embodiment. Wherein, each positive electrode plate 2 and each negative electrode plate assembly 3 are placed alternately along the direction of the predetermined axis, and at the same time, an ion semi-permeable plate is provided between each adjacent positive electrode plate assembly 2 and negative electrode plate assembly 3 Membrane module 1. It should be noted that, in this embodiment, there are twelve positive electrode plate assemblies 2 and negative electrode plate assemblies 3 in total. Of course, the positive electrode plate assembly 2 and the negative electrode plate assembly can be adjusted according to actual preparation requirements in practical applications. The number of compo...

Embodiment approach 3

[0114] The third embodiment of the present invention relates to a disinfectant manufacturing equipment, such as Figure 13 As shown, it includes: a liquid supply tank 100, a water supply tank 200, a liquid storage tank 300, a water storage tank 400, and two electrolysis devices as described in the second embodiment. Moreover, any one of the electrolysis devices can be used as a liquid-inlet electrolysis device, while the other electrolysis device can be used as a liquid-out electrolysis device.

[0115] Among them, in this embodiment, such as Figure 13 As shown, the liquid supply tank 100 is used to store potassium hydroxide solution, and the liquid supply tank 100 has a liquid supply end 1001 , and the liquid storage tank 300 has a liquid inlet end 3001 . Secondly, the water supply tank 200 is used to store pure water, and the water storage tank 200 has a water supply end 2001 , and the water storage tank 400 has a water inlet end 4001 .

[0116] Additionally, if Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com