A construction recycling aggregate screening device

A technology for recovering aggregates and screening devices, which is applied in the direction of solid separation, magnetic separation, and separation of solids from solids with airflow, which can solve the problems of normal operation interference, non-compliance, and surrounding environmental pollution by the staff, and achieve It is convenient for stacking or transshipment, avoiding airflow overflow, and improving the screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

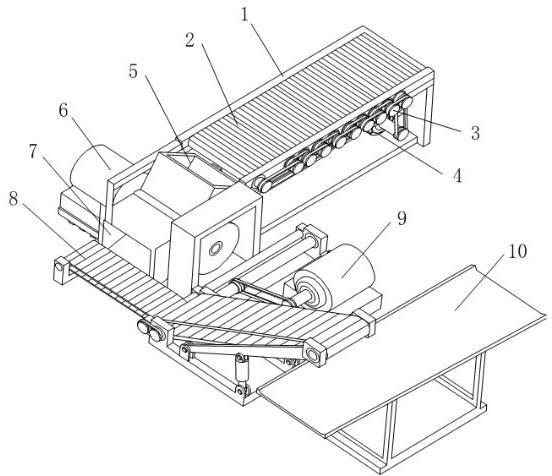

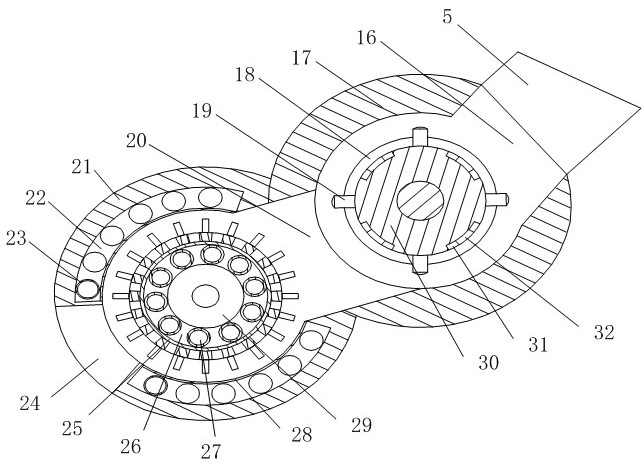

[0031] Such as Figure 1 to Figure 8 As shown, the present embodiment includes a frame 1, on which a primary conveyor belt 2 and a screening chamber 6 are sequentially arranged, and the two ends of the screening chamber 6 are respectively provided with a material inlet 5 and a material outlet 7, The discharge end of the primary conveyor belt 2 corresponds to the feed port 5 of the screening chamber 6, and a screening cylinder 21 is arranged in the screening chamber 6, and the feed port of the screening cylinder 21 communicates with the feed port 5 , the discharge port 24 of the screening cylinder 21 communicates with the discharge port 7; a screening roller 29 is rotated in the screening cylinder 21, and there is an air suction on the inside along the circumferential direction of the screening roller 29. Cavity 26, a plurality of suction pipes 27 whose axes are parallel to the axis of the screening roller 29 are sequentially arranged in the suction cavity 26, and a plurality o...

Embodiment 2

[0036] Such as Figure 1 to Figure 8 As shown, in this embodiment, on the basis of Embodiment 1, a plurality of exhaust pipes 23 are distributed at equal intervals in the exhaust chamber 22, and each of the exhaust pipes 23 faces the screening roller 29 A plurality of air injection holes 13 are opened on the side wall of each side wall, and a plurality of air injection holes 13 on two adjacent exhaust pipes 23 are distributed in a staggered manner, each of the air injection holes 13 and the outer peripheral wall of the screening roller 29 The spacing is the same; there are multiple exhaust pipes 23 in the exhaust cavity 22, and the airflow injected in the exhaust pipes 23 can screen the dust mixed in the aggregate during movement, so that the dust can enter the suction hole along the air hole. In the trachea 27, and the level of the screening cylinder 21 is relatively low, the exhaust cavity 22 is set in an inferior arc shape, and the central angle corresponding to the arc of ...

Embodiment 3

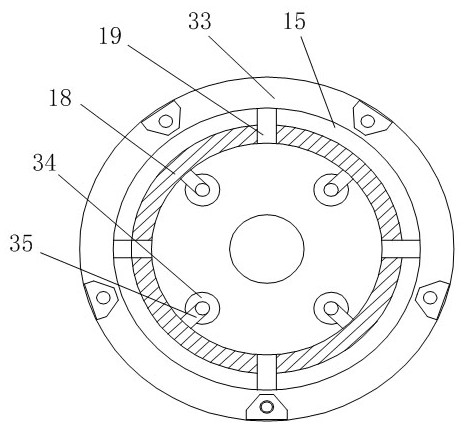

[0040] Such as Figure 1 to Figure 8 As shown, on the basis of Embodiment 1, the present embodiment is provided with a sorting cylinder 17 communicated with the screening cylinder 21 in the screening cavity 6, the two ends of the sorting cylinder 17 are open, and the two ends The cover 33 is rotatably arranged at both ends of the sorting cylinder 17 and is used to close its open end. The two ends of the roller 30 are respectively connected with the end covers 33, and a plurality of holes are arranged at intervals along the axial direction of the roller 30 on its outer peripheral wall. Stop bar 19, and between adjacent two stop bars 19, magnetic suction plate 18 is slidably arranged, and any one end cover 33 is provided with the arc-shaped hole that passes for magnetic suction plate 18, and the end of magnetic suction plate 18 After moving through the arc-shaped hole, it extends outwards, and a baffle plate 15 is provided on the extension end of the magnetic suction plate 18. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com