Laser washing system

A laser and water tank technology, applied in the field of laser marking, can solve the problems of low efficiency, time-consuming and laborious, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

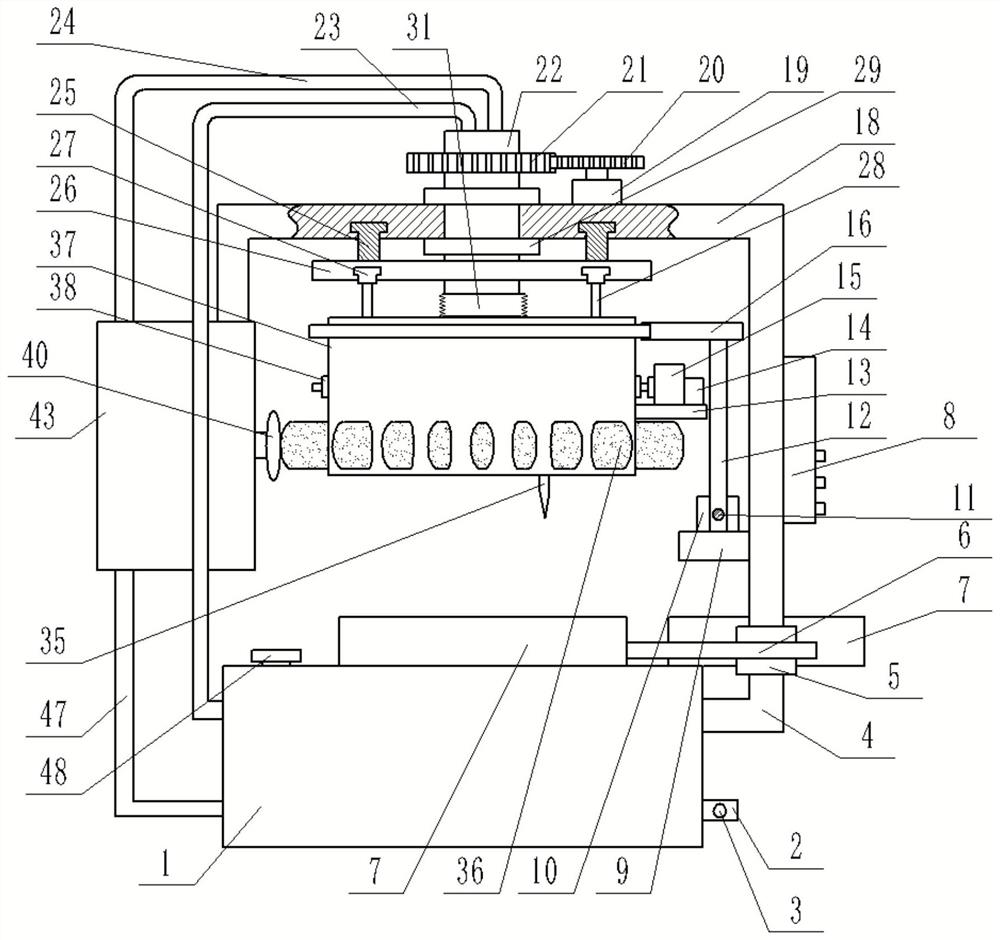

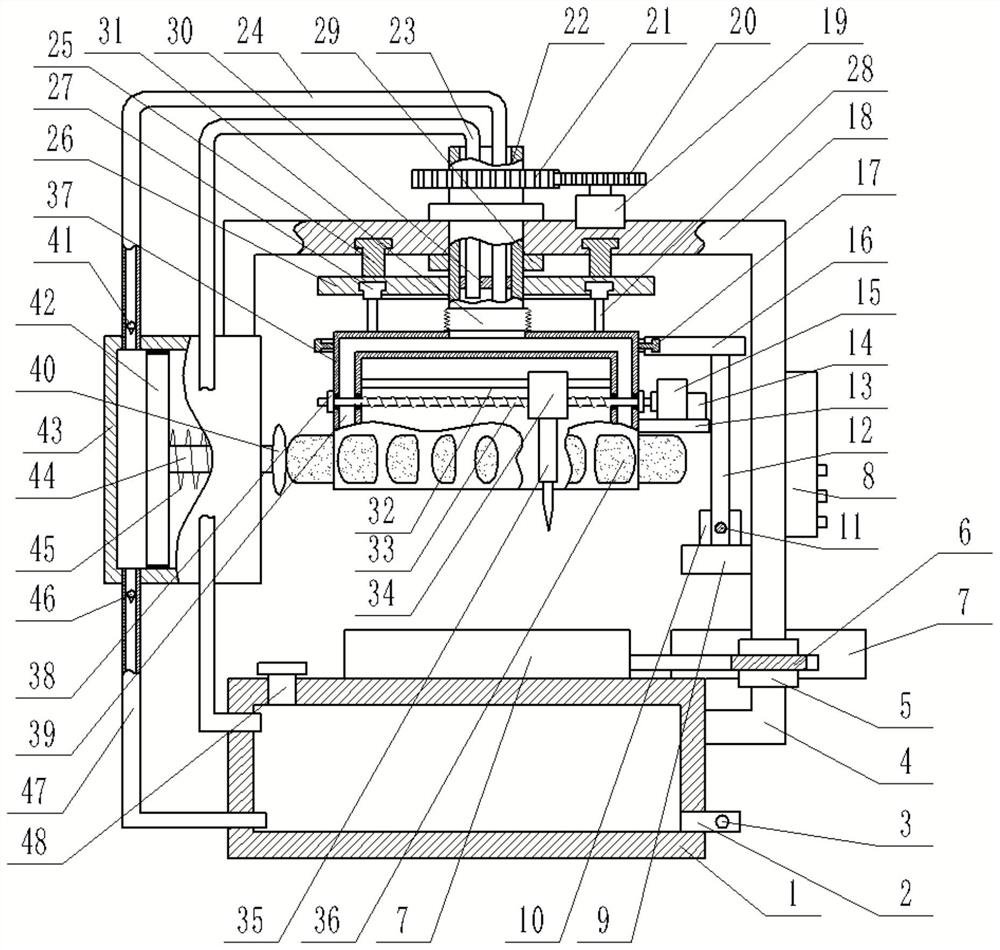

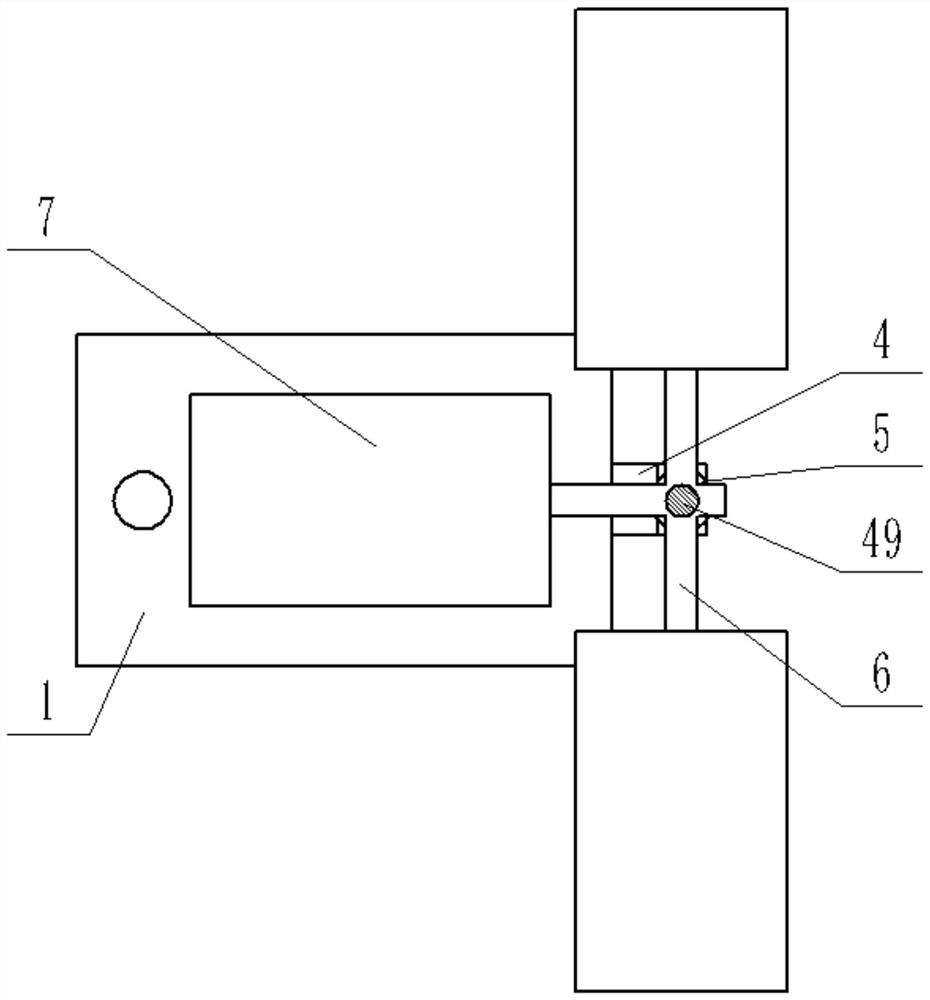

[0023] This embodiment provides a laser water washing system, such as Figure 1 to Figure 3As shown, it includes a water tank 1, the top side of the water tank 1 is provided with a water inlet 48, the water inlet 48 is threadedly connected with a cover body, and the bottom surface of one side of the water tank 1 is fixedly connected with a drain pipe 2 and connected with it. Internal communication, the drain pipe 2 is provided with a valve 3, an L-shaped plate 4 is provided directly above the drain pipe 2, the cross bar of the L-shaped plate 4 is fixedly connected to one side of the water tank 1, and the L-shaped plate 4 The top surface of the vertical bar of the plate 4 is fixedly connected with a round bar 49, the top surface of the round bar 49 is fixedly connected with an n-type plate 18, and the bottom surface of one end of the n-type plate 18 is fixedly connected with a box 43, and the round bar 49 is fixedly connected with a box body 43. 49 is covered with a cross plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com