Automatic device for collecting, separating and packaging zinc ash and using method of automatic device

An automatic device, zinc ash technology, applied in the field of automatic device, zinc ash collection, separation and packaging, can solve the problems of the remaining ash can not be automatically packaged work efficiency, less zinc ash and zinc, take up a lot of time and other problems, achieve fast packaging process, improve productivity , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

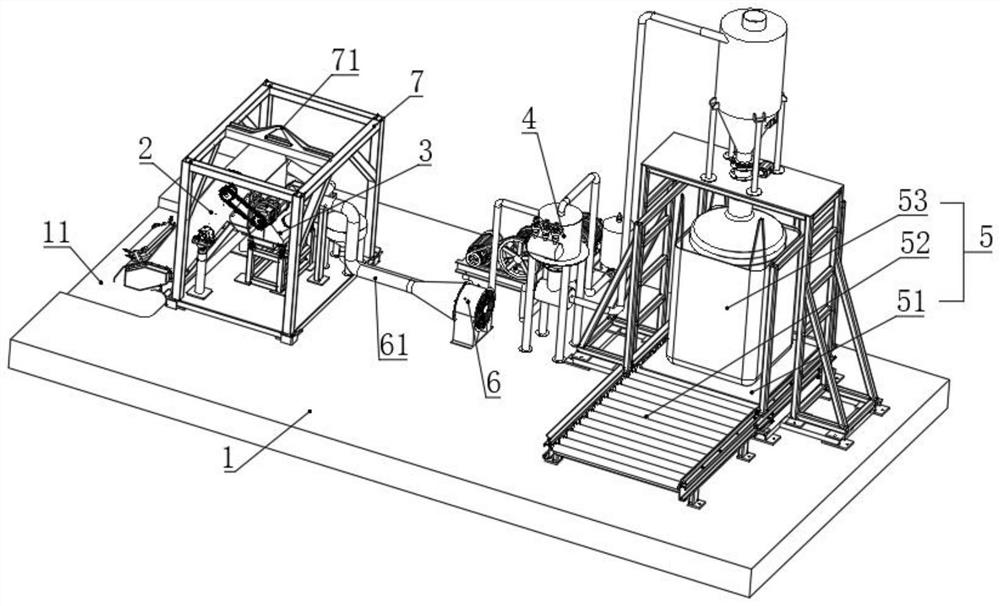

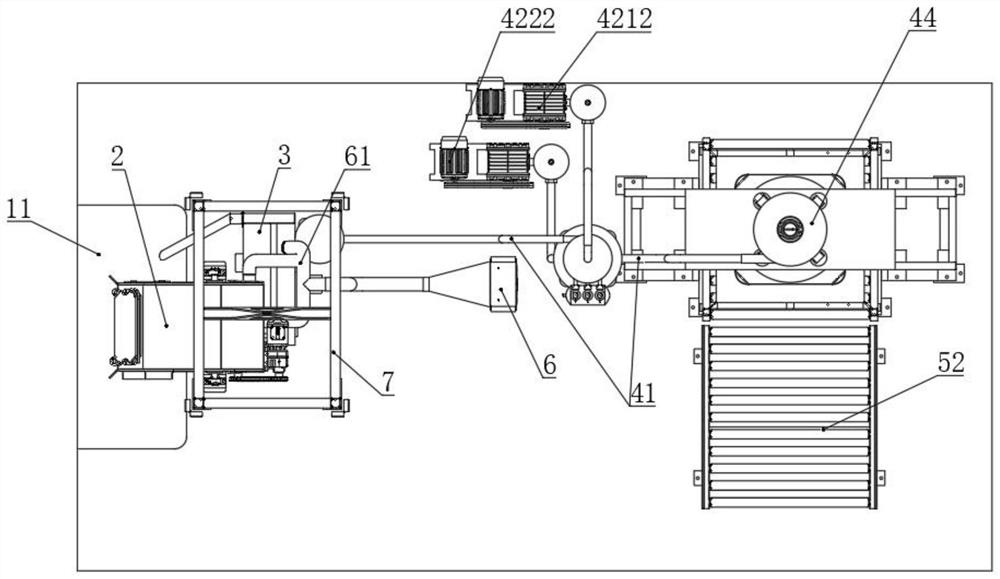

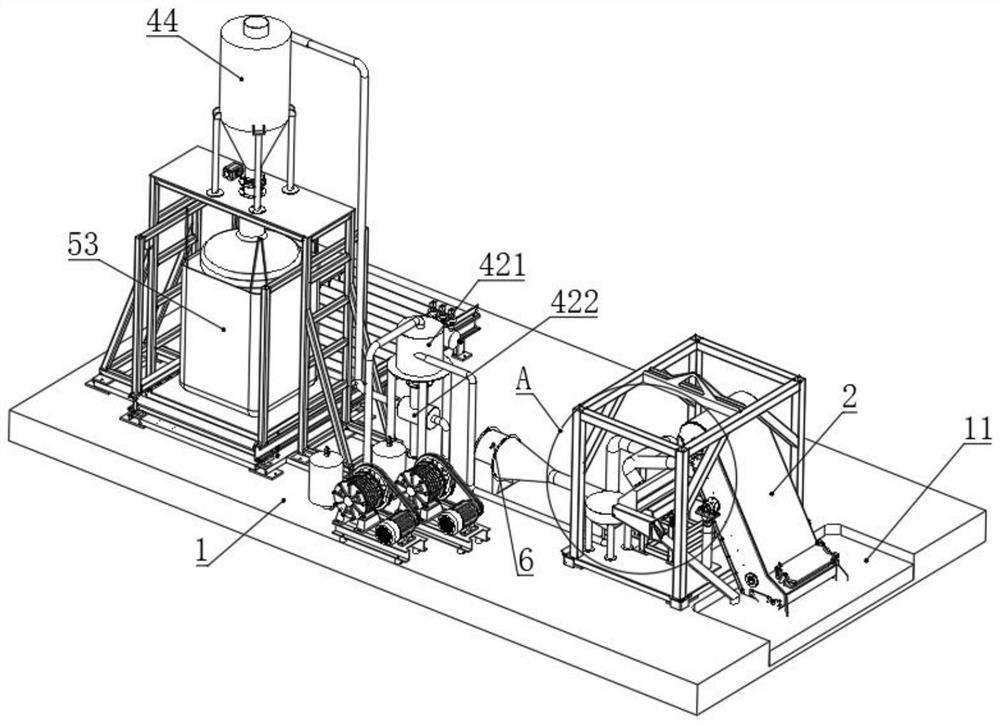

[0075] like Figure 1-8 As shown, an automatic device for collecting, separating and packaging zinc ash, including a zinc pot body 1, a zinc liquid pool 11 is provided at the left end of the zinc pot body 1, and a stirring hoist 2 and a vibrating screening machine are also provided at the right end of the zinc pot body 1 3 and the weighing conveyor 5, the left side of the stirring hoist 2 is in the zinc liquid pool 11, and the right side of the stirring hoist 2 is connected to the vibrating screening machine 3, and the vibrating screening machine 3 is connected to the weighing conveyor 5 through the conveying unit 4 ;

[0076] The vibration screening machine 3 includes a screening housing 31 and a sieve plate 32 installed inside the screening housing 31. The front end of the sieve plate 32 is higher than the rear end, and the upper part of the front end of the screening housing 31 is provided with a screening ash inlet 33. , the lower part of the screening housing 31 is also ...

Embodiment 2

[0096] This embodiment is a further improvement of the previous embodiment, such as Figure 1-8 As shown, an automatic device for collecting, separating and packaging zinc ash, including a zinc pot body 1, a zinc liquid pool 11 is provided at the left end of the zinc pot body 1, and a stirring hoist 2 and a vibrating screening machine are also provided at the right end of the zinc pot body 1 3 and the weighing conveyor 5, the left side of the stirring hoist 2 is in the zinc liquid pool 11, and the right side of the stirring hoist 2 is connected to the vibrating screening machine 3, and the vibrating screening machine 3 is connected to the weighing conveyor 5 through the conveying unit 4 ;

[0097] The vibration screening machine 3 includes a screening housing 31 and a sieve plate 32 installed inside the screening housing 31. The front end of the sieve plate 32 is higher than the rear end, and the upper part of the front end of the screening housing 31 is provided with a screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com