A hydrogel-immobilized microbial preservation method

A technology of microorganisms and hydrogels, which is applied in the field of hydrogel immobilized microorganisms preservation, can solve the problems of insufficient research on detection indicators, type control of antifreeze protection agents, inability to be widely used in production, limited number of control experiments, etc., and achieve the goal of maintaining microorganisms Vitality, prevention of cell damage, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

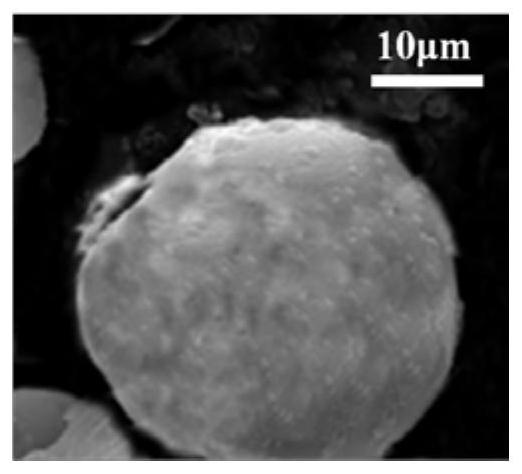

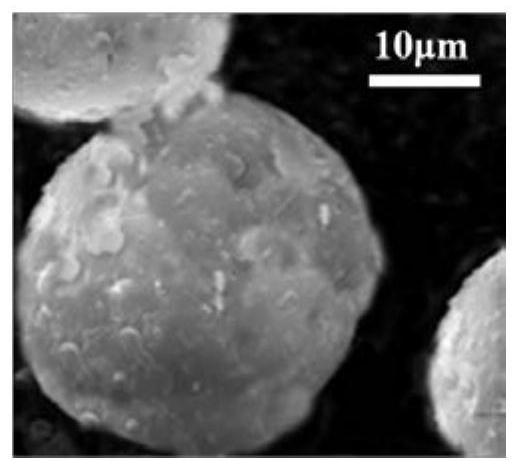

[0033] Preparation of a composite gel ball:

[0034] S1: Add the chitosan powder to the acetate solution (concentration of 2.1 %, w / w), stir until completely dissolved; add CACO under the magnetic mixing 3 (The mass ratio of the chitosan powder is 0.79: 1), stir for 12min, and then the ultrasonic 15min; then add liquid paraffin (the solid liquid to the alpine glycogen powder and the paraffin is 1g: 156ml), stir 5min violently; 43 ℃ water bath water bath; Under the conditions, add the SPAN-80 (the solid ratio of the chitosan powder and the SPAN-80 is 1g: 2.1ml), stir for 30 minutes; keep the water bath stirring, slowly add the pentalhyde solution (concentration is 24.5 %, W W, W W / w) (The solid-liquid ratio of chitosan powder and pentaldehyde solution is 1g: 2.2ml), and the cross-linked response is 65 minutes; finally add N- (1,8-diemimimazazole and [1,2-a ] 喹 4 4-4-base) -1,2-ethyleine (the mass ratio of the chitosan powder is 1.87: 1), after the stirring reaction is 70min, add 5...

Embodiment 2

[0037] The difference between the preparation and embodiment 1 of a composite gel ball is:

[0038] CACO in Step S1 3 The mass ratio of the chitosan powder is 0.76: 1; the solid-liquid ratio of the chitosan powder and the pentalaldal solution is 1 g: 2ml; n- (1,8-two-gymiimazole and [1,2-a]基-4 -4-Bidth) -1,2-The mass ratio of ethyltramia and chitosan powder is 1.80: 1;

[0039] Step S2 The mass ratio of the middle product M and sodium alginate is 1: 0.8 to 1.2; the solid -liquid ratio of sodium alginate and calcium chloride solution is 0.1g: 18.4ml.

Embodiment 3

[0041] The difference between the preparation and embodiment 1 of a composite gel ball is:

[0042] CACO in Step S1 3 The mass ratio of the chitosan powder is 0.81: 1; the solid-liquid ratio of chitosan powder and pentalaldal solution is 1 g: 2.3ml; n- (1,8-diemimidazole and [1,2-a a ] 喹 4 啉 -4-base) -1,2-the mass ratio of ethyltramia and chitosan powder is 2.01: 1;

[0043] The quality ratio of the middle product M and sodium alginate in the step S2 is 1: 1.16; the solid -liquid ratio of sodium alginate and calcium chloride solution is 0.1g: 23.6ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com