Construction method of integrated roof joint structure

A construction method and construction technology, applied in the direction of roofing, manufacturing tools, roof covering layer, etc., can solve the problems of roof leakage, long construction period, complicated operation, etc., and achieve easy waterproof replacement, low repair cost, guarantee engineering quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description.

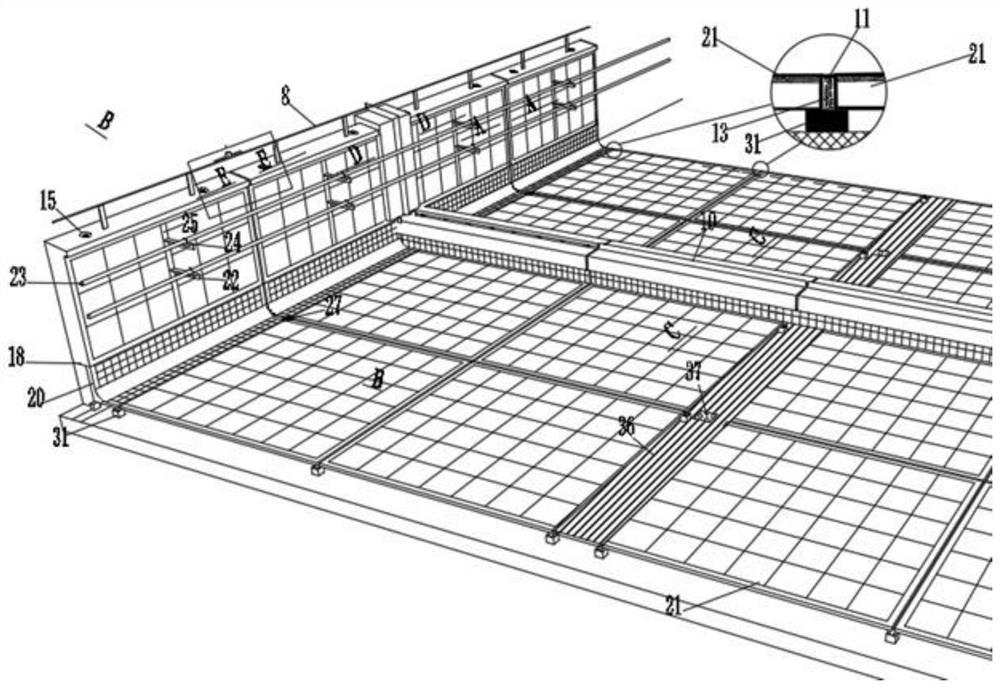

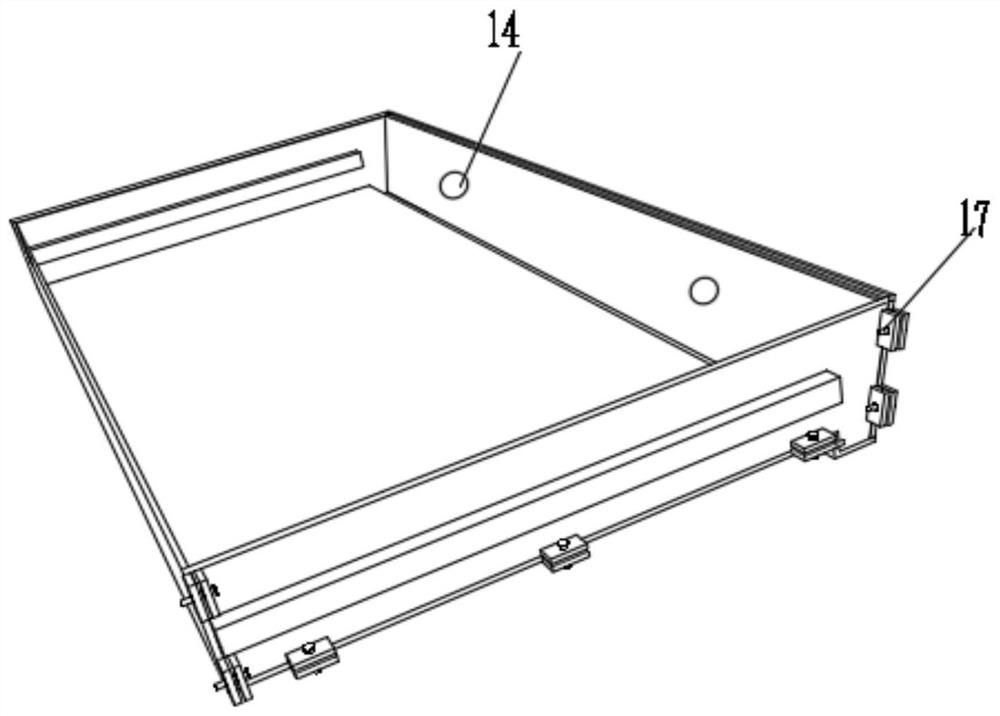

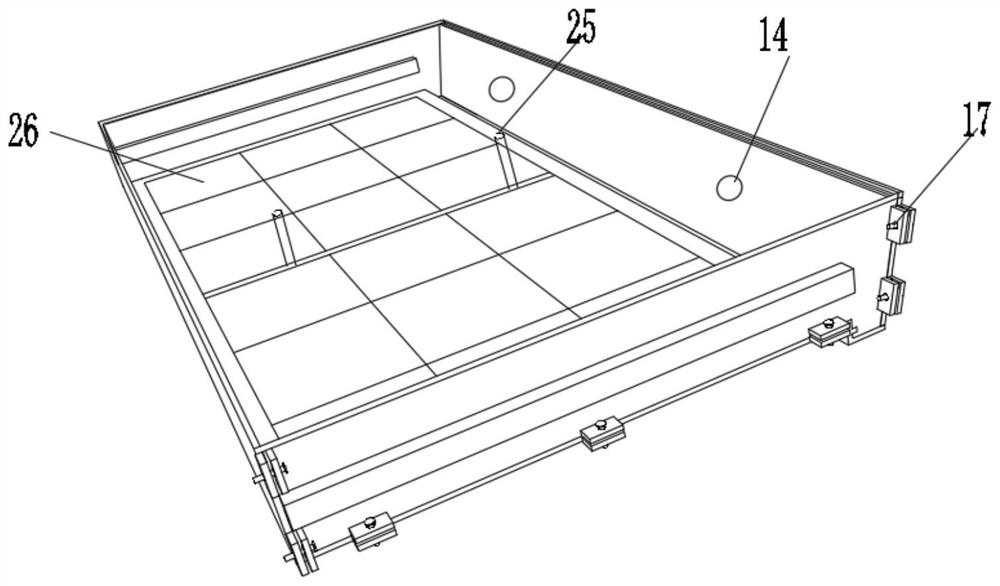

[0072] The forming effect of adopting the roof integrated construction method of the present invention is as follows: figure 1 As shown, a plurality of prefabricated walls 1 are formed by hoisting and splicing, wherein one side of the prefabricated wall 1 is provided with an articulation part, and the opposite side is provided with a groove matching the articulation part, and two adjacent The prefabricated walls 1 are connected by the occlusal part and the groove occlusal, and the joints of the prefabricated walls 1 are filled with asphalt hemp fiber 13, and the surface is sealed with weather-resistant glue 11. For d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com