Online sealing performance measurement sealing plug for small-caliber nuclear-grade check valve

A check valve and small-diameter technology, applied in the mechanical field, can solve the problems of unguaranteed sealing measurement results, inability to install, difficult installation, etc., and achieve the effects of shortening installation time, ensuring sealing performance, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

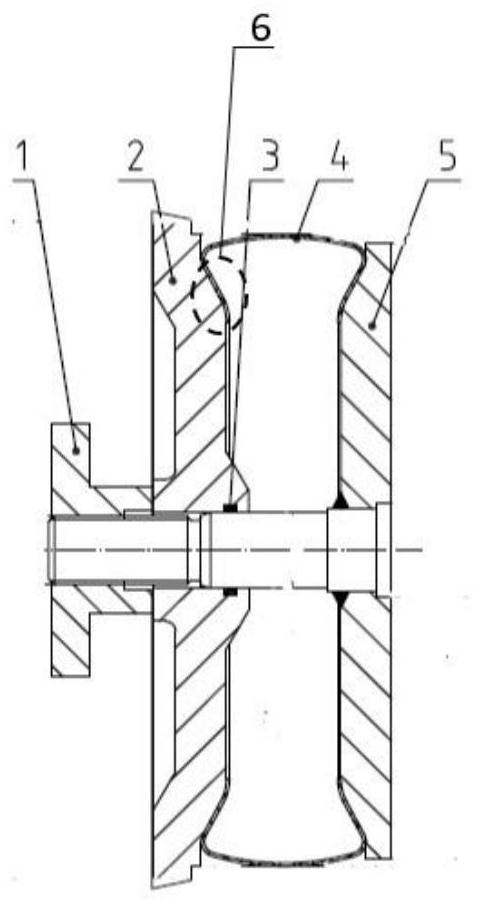

[0021] Such as figure 1 As shown, the sealing plug includes 5 parts: tightening nut 1, baffle A2, O-ring 3, annular rubber plug 4, and baffle B5.

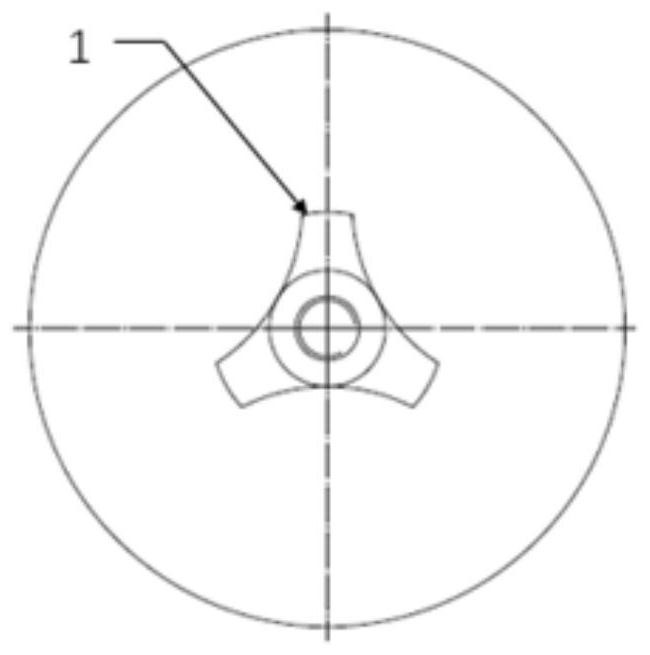

[0022] Such as figure 2 As shown, the tightening nut 1 has a special three-claw (corner) holding design, which is convenient for direct tightening by hand, without tools, which greatly simplifies the installation process and has strong operability.

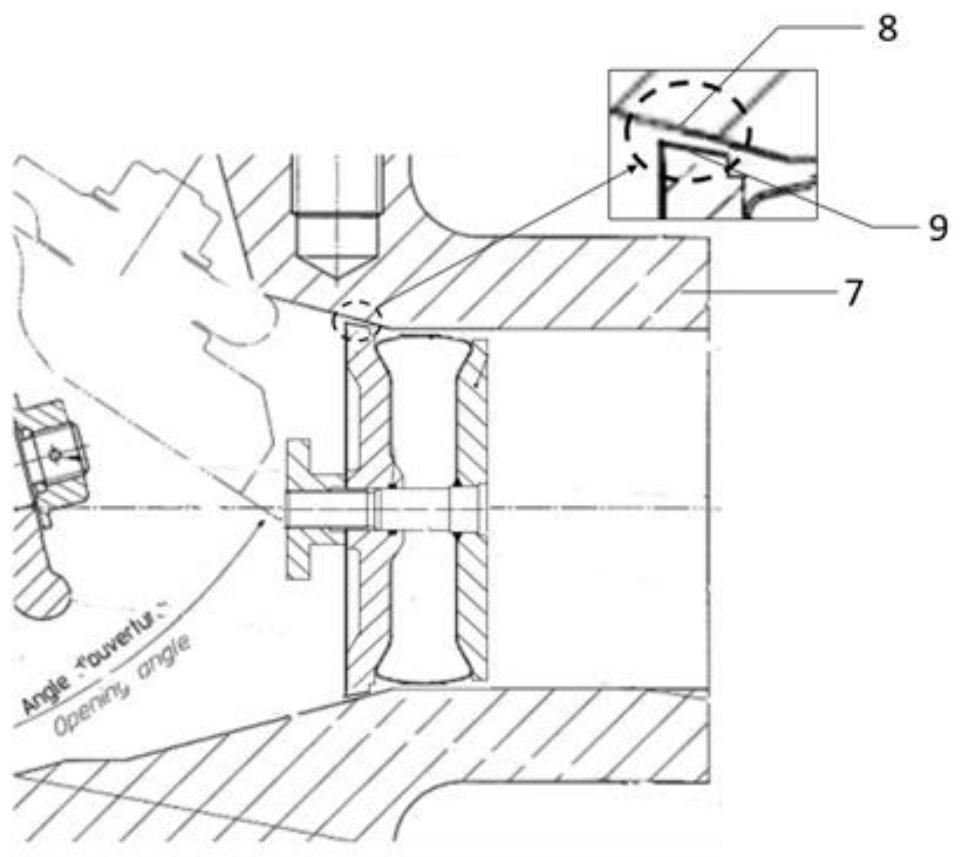

[0023] Such as image 3 As shown, the diameter of the outer circle of the baffle 5 is slightly smaller than the diameter of the outlet side of the valve body 7, the diameter of the outer circle of the baffle 2 is slightly larger than the diameter of the outlet side of the valve, and the inclination angle 9 of the cone surface of the baffle A2 is smaller than the inclination angle 8 of the inner cavity of the valve. The round design makes it possible to quickly center the sealing plug and not get stuck in the inner cavity of the valve when installing the sealing plug, and also ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com