Wear detection device for superhard cutter

A technology of tool wear and detection device, which is applied in the direction of measuring device, cleaning method and utensil, cleaning method using liquid, etc., can solve problems such as poor detection effect of superhard tool wear, and achieve the effect of avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

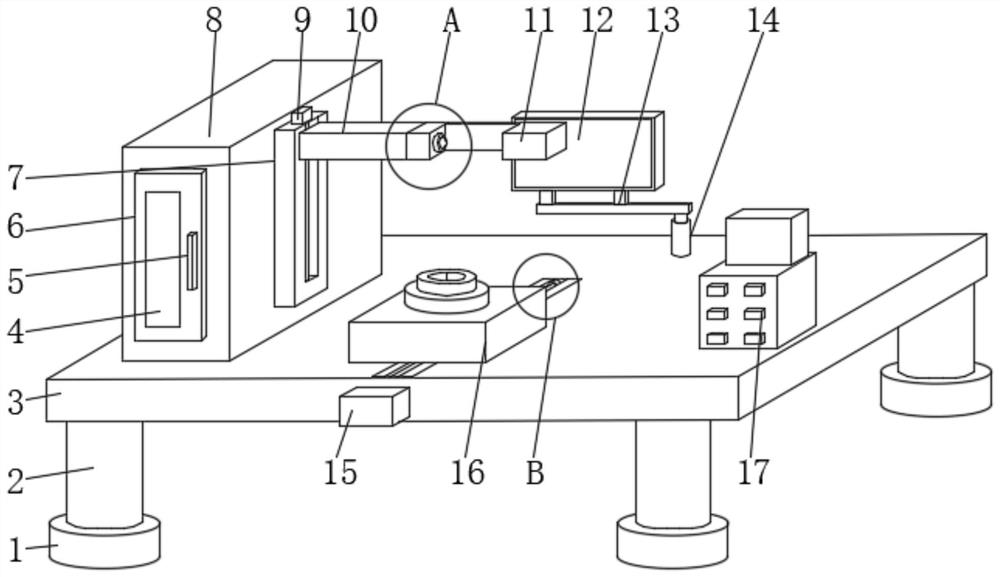

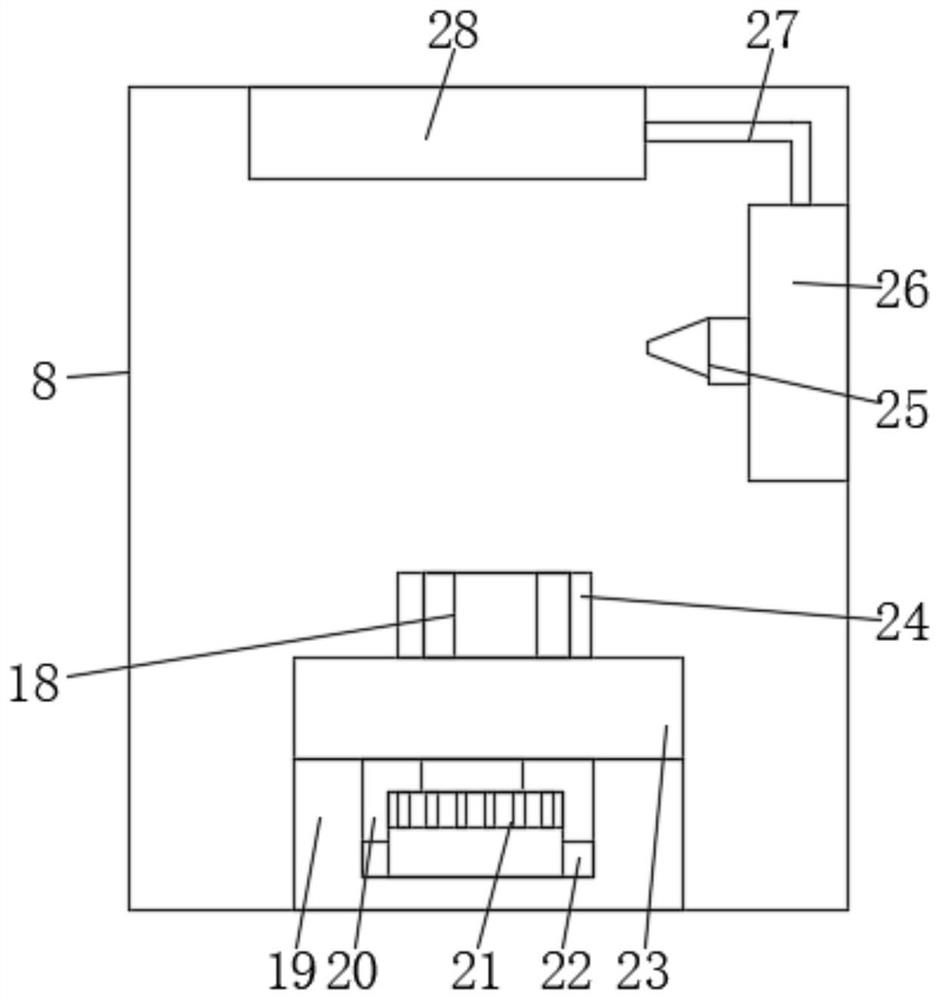

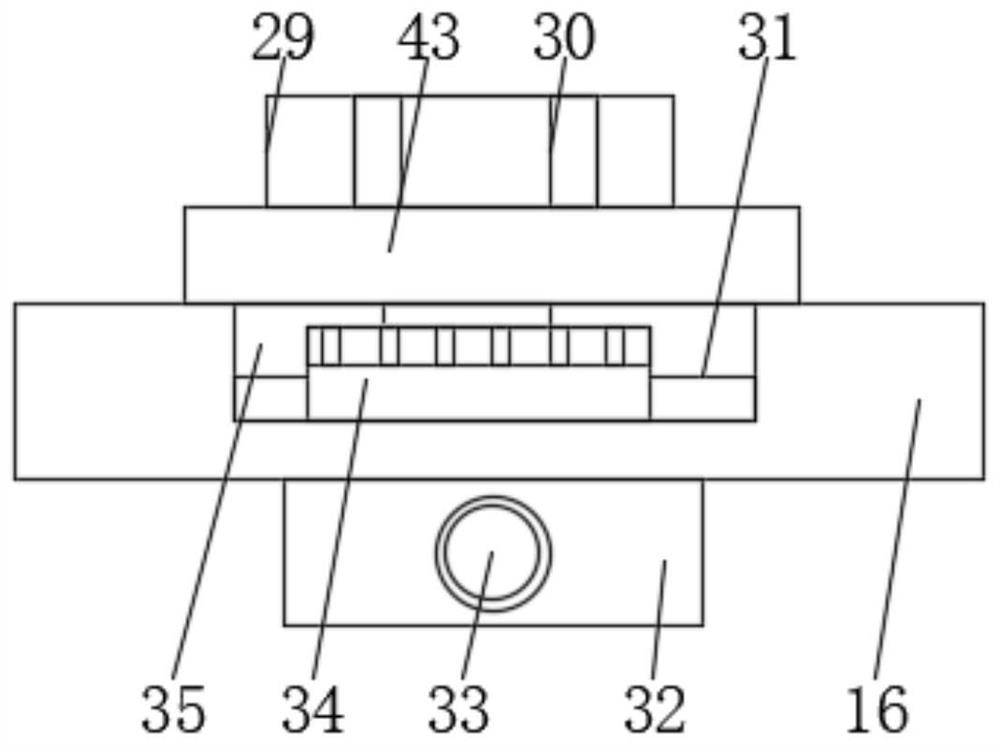

[0032] Such as Figure 1-6 As shown, the embodiment of the present invention provides a wear detection device for superhard cutting tools, including a support platform 3, a detector 17 is fixedly connected to the right side of the upper end of the support platform 3 for data collection, and the left side of the upper end of the support platform 3 The box body 8 is fixedly connected, the inner upper end of the box body 8 is provided with a water delivery device 28, the right side of the box body 8 is provided with a sprayer 26, and a conduit 27 is arranged between the water delivery device 28 and the sprayer 26, and the sprayer 26 The left side of the box is provided with a spray head 25, the inner lower end of the box body 8 is provided with a support block 19, the upper end of the support block 19 is provided with a first rotating groove 20, and the inner lower end of the first rotating groove 20 is provided with a third motor 21, The upper end of the third motor 21 is extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com