Anti-termite butterfly-shaped optical cable and manufacturing method thereof

A termite butterfly and optical cable technology, which is applied in the field of optical communication transmission, can solve the problems of easily polluted environment for production and use, complex indoor wiring environment, and difficult to find breakpoints, etc., and achieves good anti-term effect, mechanical performance and environmental performance. Low, significant anti-ant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

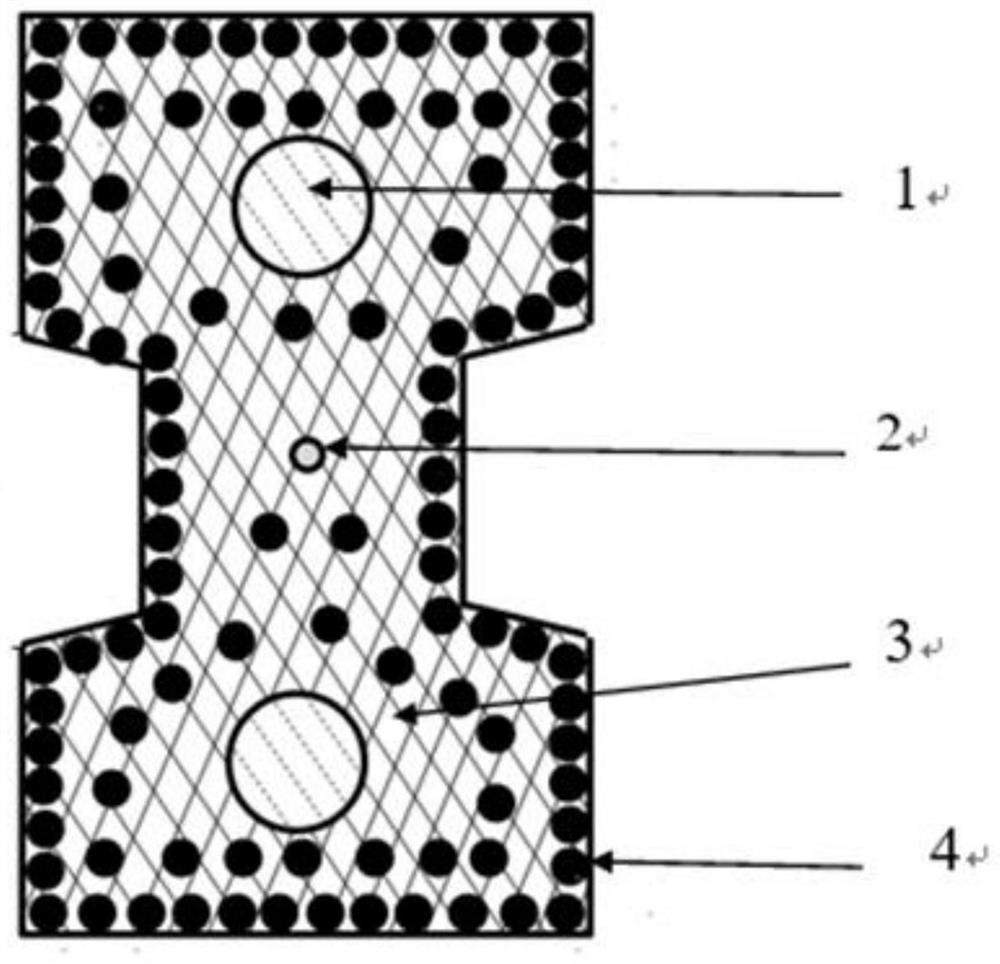

[0022] An example of the present invention is figure 1 As shown, a sheath 3 with a rectangular cross-section is included, and a groove shrinking from the outside to the inside is arranged in the middle of the left and right sides of the sheath corresponding to the optical fiber unit. The groove is trapezoidal, and the outside is large and the inside is small. The sheath It is made of low-smoke, halogen-free, flame-retardant polyolefin, and anti-ant microbeads 4 are mixed in the sheath. Covered with an anti-termite agent, the anti-termite agent is an anti-termite solution and an anti-termite powder, that is, a solvent capsule and a powder capsule are mixed and used in a weight ratio of 6:4, and the type of the anti-termite agent is one or Two kinds are pyrethroid agents; the capsules are made of polymers, and the anti-termite agent accounts for 75% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com