Flame retardant Anti-termite resin composition, power cable and method for producing same

A technology of resin composition and power cable, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of high material cost, high manufacturing cost, large cable outer diameter, etc., and achieves excellent extrusion processability and termite resistance. and excellent cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] (Preparation and Performance Evaluation of Flame Retardant and Antitermite Resin Composition)

[0130] The flame-retardant and anti-termite resin composition was prepared as follows, and each sheet was obtained using it, and each evaluation was performed.

[0131] [Examples of the present invention (sheets No.1 to No.5) and comparative examples (sheets No.c1 to No.c5)]

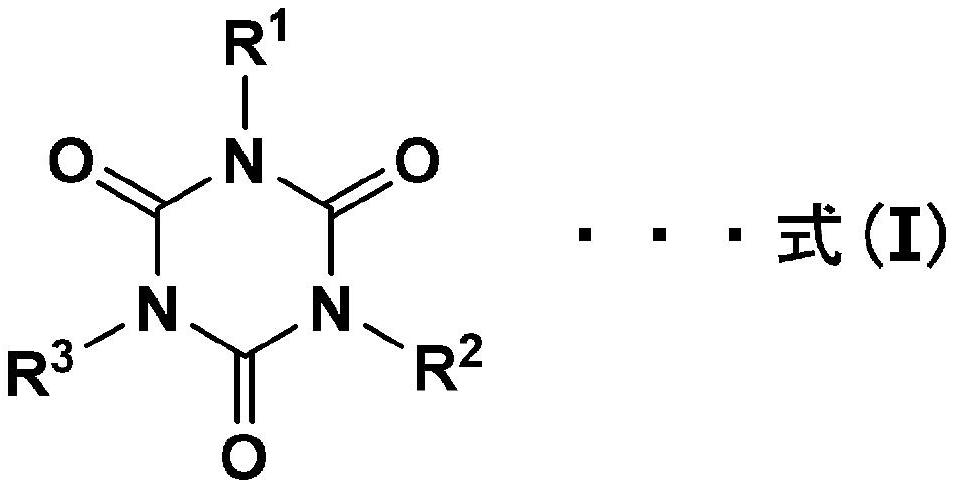

[0132] Polyvinyl chloride resin (PVC) [ZEST1400Z manufactured by Shin Dai-Ichi Vinyl Corporation, average degree of polymerization 1,400], triallyl isocyanurate [Nippon Chemical Co., Ltd. Co., Ltd. TAIC (registered trademark)] and zinc borate (FIREBREAK290 manufactured by BORAX, USA) were mixed to obtain a resin composition, which was kneaded using a roll mill set at a kneading temperature of 150°C to produce Resin, two sheet samples with different thicknesses were produced. This was press-molded at 170° C. under a pressure of 11 MPa for 15 minutes to obtain smooth sheets No.1 to No.5 and sheet No.c1 ...

Embodiment 2

[0166] (manufacturing and performance evaluation of power cables)

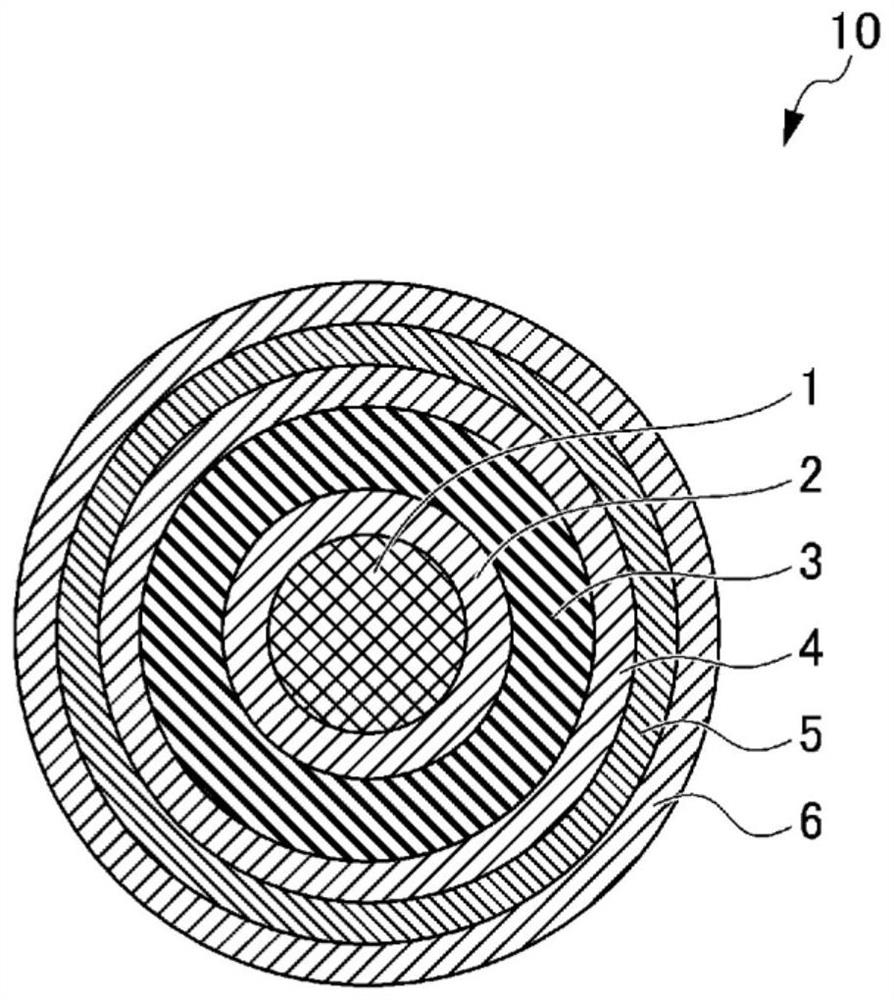

[0167] Manufactured as follows figure 1 A power cable 10 as shown has an inner semiconductive layer 2 , an insulator layer 3 , an outer semiconductive layer 4 , a shield layer 5 , and a sheath 6 in this order on the outer periphery of a conductor 1 .

[0168] 1) The making of the power cable of the example of the present invention

[0169] Use a cross-sectional area of 800mm 2 A circular compressed conductor made of copper is used as a conductor, and an internal semiconductive layer formed of cross-linked polyethylene with carbon added with a thickness of 1 mm, and a cross-linked polyethylene with a thickness of 11 mm [manufactured by NUC Co., Ltd. The insulator layer formed by insulating agent NUCV-9253], and the outer semiconductive layer formed by cross-linked polyethylene with added carbon with a thickness of 0.5 mm.

[0170] Then, a shielding layer with an aluminum metal added to the outer periphery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com