PVC sheathing material for anti-ant cables and preparation method thereof

An anti-ant cable and sheath material technology, applied in the field of PVC sheath material, can solve the problems of high cost, holes in the PVC sheath material, easy to be damped or soaked in water, etc. The effect of improving the anti-ant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

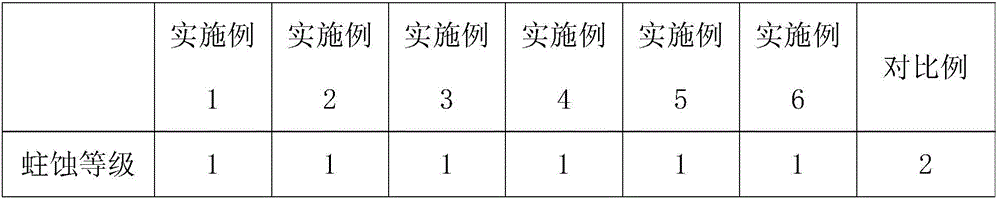

Examples

Embodiment 1

[0029] The PVC sheath material used for termite-resistant cables consists of: 100 parts by weight of PVC, 6 parts of compound anti-termite agent of Zanthoxylum bungeanum, 10 parts of calcined kaolin, 0.5 parts of silane coupling agent, 1.2 parts of chlorinated paraffin, calcium-zinc compound 7 parts of stabilizer, 1.4 parts of ACR, 6.5 parts of aluminum hydroxide, 20 parts of DOP;

[0030] The preparation steps of the compound anti-termite agent of Chinese prickly ash are:

[0031] A. Wash the Zanthoxylum bungeanum fruit and dry it, grind it and sieve it to obtain the Zanthoxylum bungeanum fruit powder, wrap the Zanthoxylum bungeanum fruit powder with filter paper, add it to a Soxhlet extractor, add chloroform and start reflux extraction, the weight of Zanthoxylum bungeanum fruit powder and chloroform The ratio is 1:5, while heating in a water bath, the heating temperature is 70°C, reflux extraction until the outflowing liquid is colorless, stop the extraction, and place the o...

Embodiment 2

[0036] The PVC sheath material used for termite-proof cables consists of: 100 parts by weight of PVC, 8 parts of compound anti-termite agent of Zanthoxylum bungeanum, 5 parts of light calcium carbonate, 0.2 parts of silane coupling agent, 2 parts of chlorinated paraffin, calcium Zinc composite stabilizer 5.5 parts, ACR 1.8 parts, aluminum hydroxide 7 parts, DOP 25 parts.

[0037] Its preparation method and the preparation steps of the Zanthoxylum bungeanum anti-termite agent are the same as in Example 1.

Embodiment 3

[0039] The PVC sheath material used for termite-proof cables consists of the following parts by weight: 100 parts of PVC, 7.5 parts of compound anti-termite agent of Zanthoxylum bungeanum, 25 parts of light calcium carbonate, 0.4 parts of silane coupling agent, 1.5 parts of chlorinated paraffin, calcium 8 parts of zinc composite stabilizer, 1.5 parts of ACR, 9 parts of aluminum hydroxide, 15 parts of epoxy soybean oil.

[0040] Its preparation method and the preparation steps of the Zanthoxylum bungeanum anti-termite agent are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com