Mixing chamber structure for prism type high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and prismatic technology, applied in the field of reactors, can solve the problems of prismatic high-temperature gas-cooled reactor without mature design and no mixing chamber 5 structure, and achieve the effect of improving safety and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

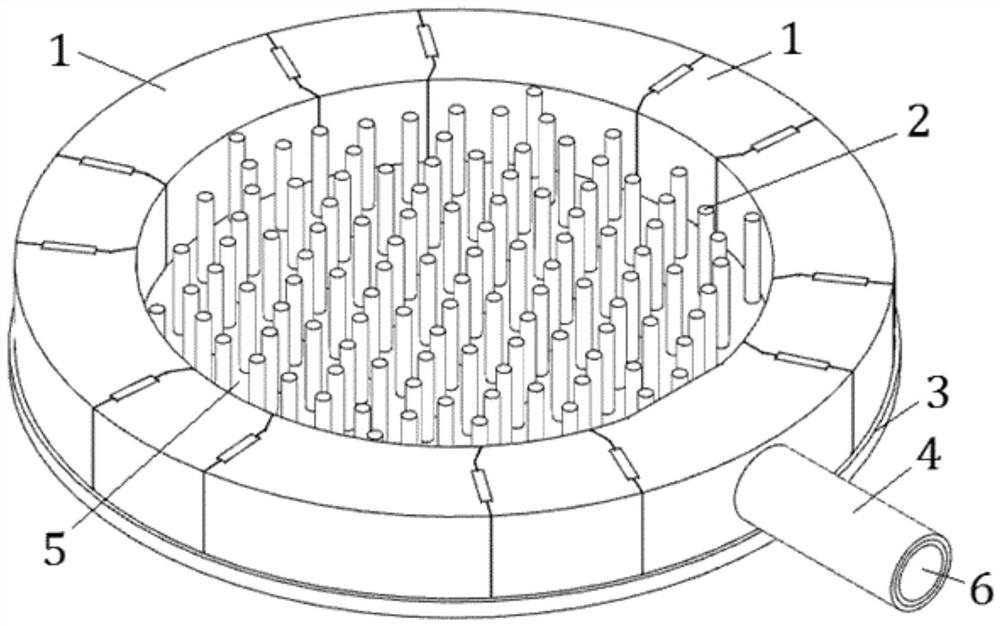

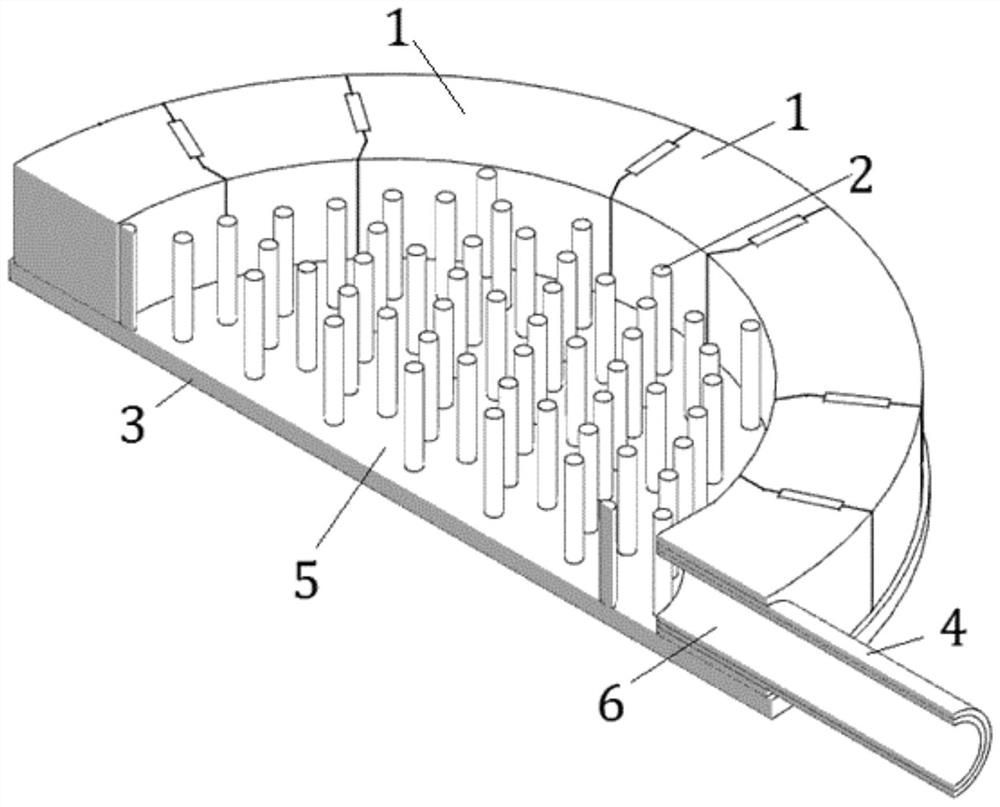

[0019] Such as figure 1 , figure 2 As shown, a mixing chamber structure for a prismatic high-temperature gas-cooled reactor provided by the present invention is arranged at the bottom of a prismatic high-temperature gas-cooled reactor, wherein the side walls made of graphite and the bottom plate 3 made of metal are common The mixing chamber 5 formed is sealed and connected between the side wall and the bottom plate 3, the side wall is connected with the bottom of the prism-type high-temperature gas-cooled reactor, and an outlet flow channel 6 is also provided on the side wall. The coolant channel of the reflection layer under the core of the type high temperature gas-cooled reactor is connected, and the outlet flow channel 6 on the side of the mixing chamber 5 is connected with the core outlet channel. The coolant flowing out from the bottom of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com