3D printing device

A technology of 3D printing and mounting board, which is applied in the direction of 3D object support structure, additive manufacturing, processing and manufacturing, etc. It can solve the problems of rough surface of the model, affecting the smoothness of the model, and affecting the printing effect, so as to prevent surface roughness and ensure Texture, cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

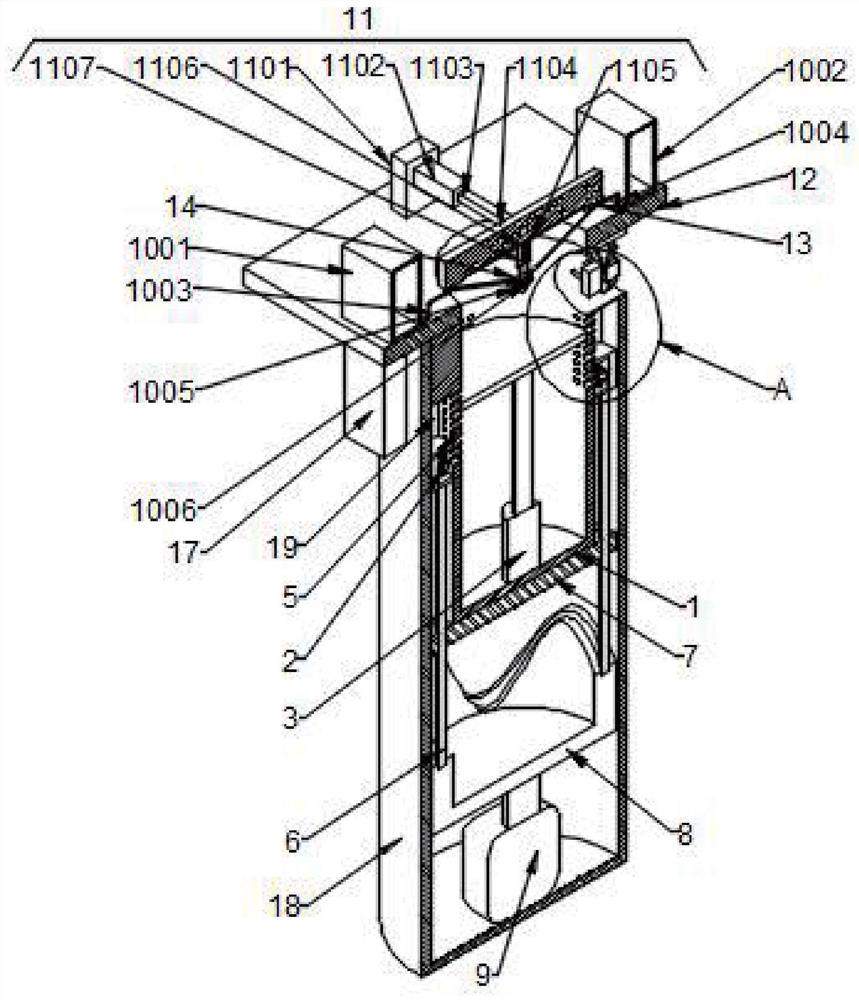

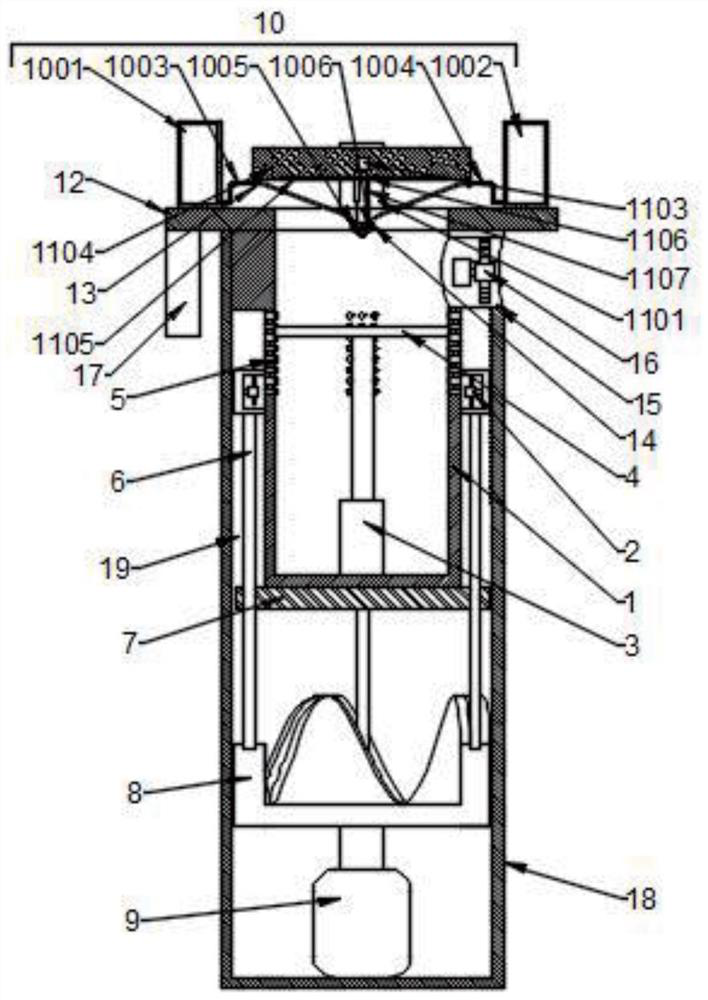

[0022] see Figure 1~6 , a 3D printing device, comprising an outer cylinder 18, an inner cylinder 1 is fixedly installed on the upper part of the outer cylinder 18, the upper end of the inner cylinder 1 is in an open state, and the outer surface of the cylinder around the inner cylinder 1 is provided with a The indwelling groove 19 in the vertical state is provided with a fan 2 in the indwelling groove 19, and the fan box of the fan 2 corresponds to the size of the indwelling groove 19, and the upper part of the inner surface of the inner tube box 1 corresponds to the indwelling groove 19 and is provided with several through holes 5 at intervals. , the middle part of the outer surface of the lower end of the fan box 2 is fixedly connected with a connecting rod 6, and the outer surface of the lower end of the inner cylinder box 1 is fixedly installed with a cross 7, and the connecting rod 6 runs through the middle part of the four corners of the cross 7, and the inner bottom of ...

Embodiment 2

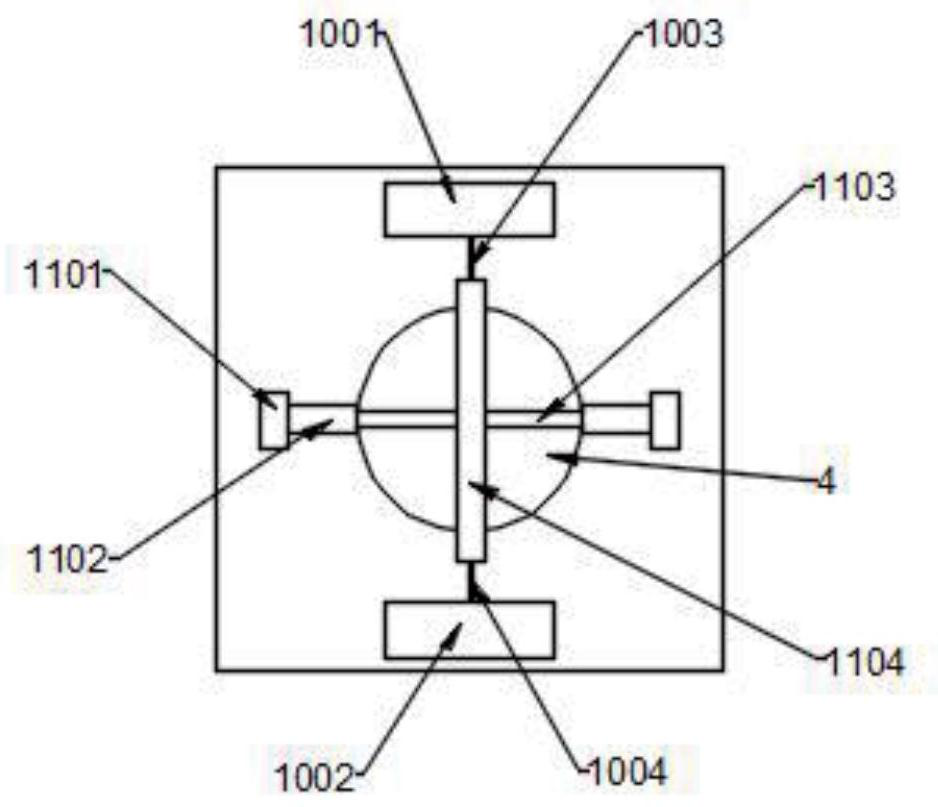

[0024] see Figure 1~6, under the condition that other parts are all the same as in Embodiment 1, the difference between this embodiment and Embodiment 1 is that the outer surface of the upper end of the outer cylinder box 18 is fixedly installed with a mounting plate 12, and the mounting plate 12 corresponds to the upper end of the inner cylinder box 1. The opening is provided with a mouth, and the middle part of the lower surface of the front end of the mounting plate 12 is fixedly installed with a model reader 17, and the upper surface of the mounting plate 12 is provided with a mobile structure 11. The mobile structure 11 includes a support block 1101, and the support block 1101 is fixedly installed. On both sides of the middle part of the mounting plate 12, the upper part of the outer surface of the supporting block 1101 close to one side is fixedly equipped with a connecting block 1102, and a sliding block 1103 is installed between the middle part of the adjacent end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com