Inner supporting device for installing large pressure steel pipe

A support device and penstock technology, which is applied in the field of internal support devices for large penstock installations, and can solve the problems of laborious adjustment, large occupation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

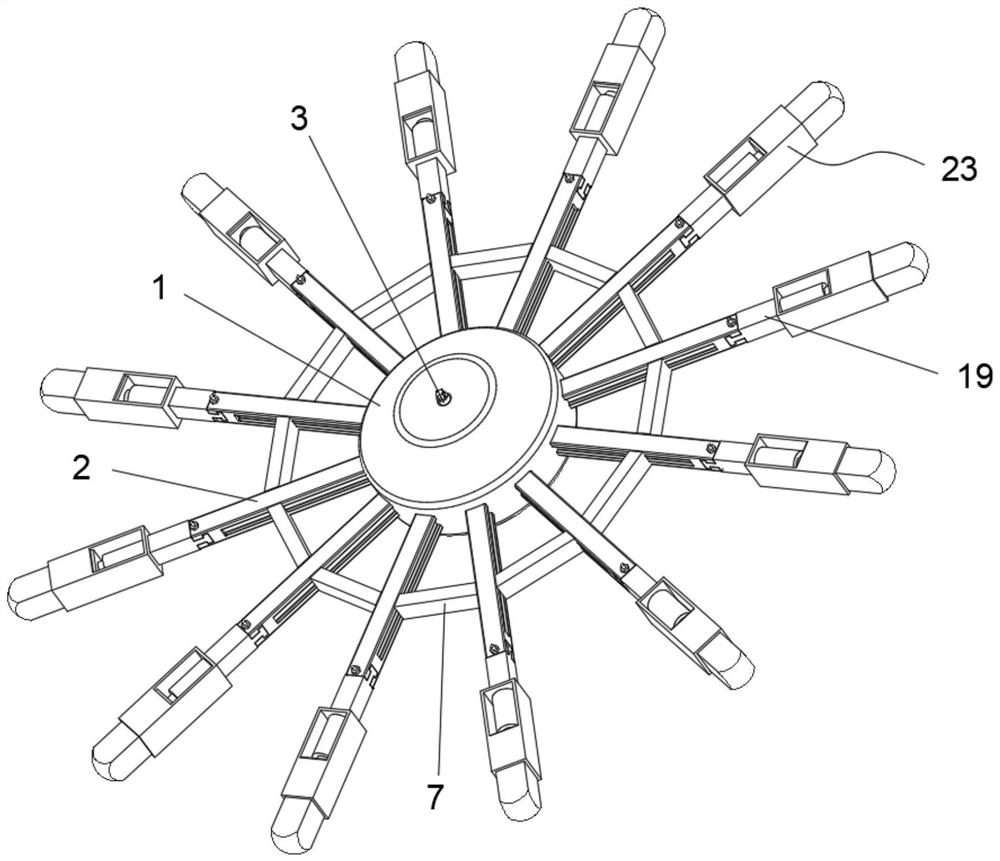

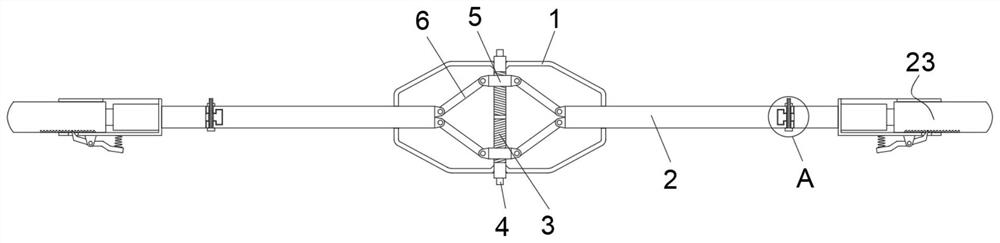

[0044] see Figure 1-7 , an inner support device used for the installation of large pressure steel pipes, including a hydraulic system and an inner support device body, the inner support device body includes a shell 1, the outer wall of the shell 1 is circumferentially distributed with a plurality of support arms 2, the support arms One end of 2 runs through the outer wall of the housing 1, and the housing 1 is provided with a drive mechanism, and one end of the support arm 2 located in the housing 1 is connected to the drive mechanism, and the drive mechanism is used to adjust the length of the support arm 2 extending out of the housing 1. The driving mechanism includes a first two-way screw 3, the two ends of the first two-way screw 3 pass through the inner wall of the housing 1 and are fixedly connected with a rectangular block 4, the first two-way screw 3 is rotationally connected with the housing 1, and the outer wall of the first two-way screw 3 There are two threaded sl...

Embodiment 2

[0069] Concrete combination Figure 7 , the difference between this embodiment and embodiment 1 is:

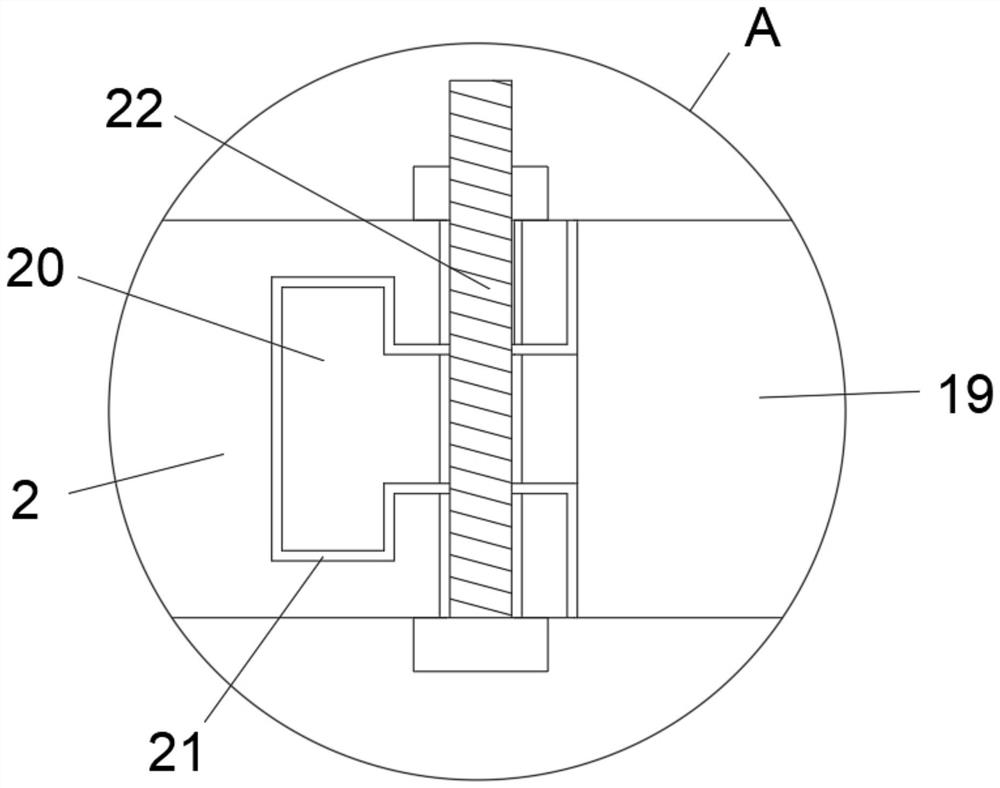

[0070] The support pile 23 comprises a hollow shell 24, the hydraulic cylinder 26 is positioned at the hollow shell 24, the outer wall of the hollow shell 24 is provided with an operation port 25 for taking out / putting in the hydraulic cylinder 26, and the inner wall of the hollow shell 24 is slidably connected with a movable block 33, the movable block The end face of 33 is offset against the movable end of hydraulic cylinder 26, and the outer wall of movable block 33 is fixedly connected with second top pile 34, and one end of second top pile 34 runs through the inner wall of hollow shell 24, and the outer wall of second top pile 34 is provided with the first Two limit mechanisms, the outer wall of the second top pile 34 is provided with a scale bar 37 .

[0071] When the support of the penstock by the second jacking pile 34 is in place, the second jacking mechanism can be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com