Combined pile type structure and construction method for treating insufficient bearing capacity of deep foundation pit construction pile by adopting combined pile type structure

A combined, construction pile technology, applied in the direction of foundation structure engineering, foundation structure test, sheet pile wall, etc., can solve the problem of insufficient bearing capacity and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

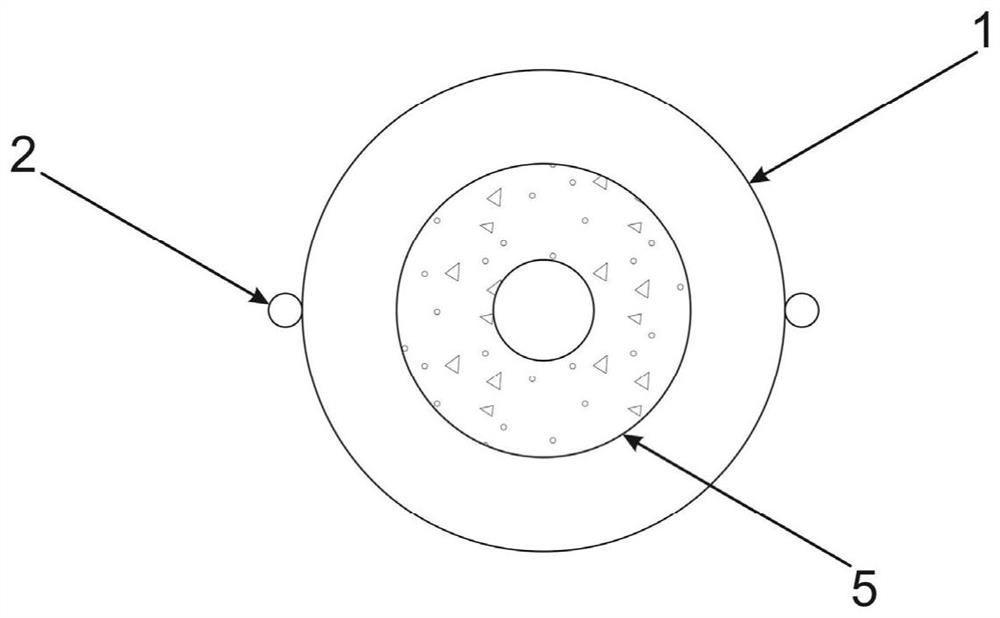

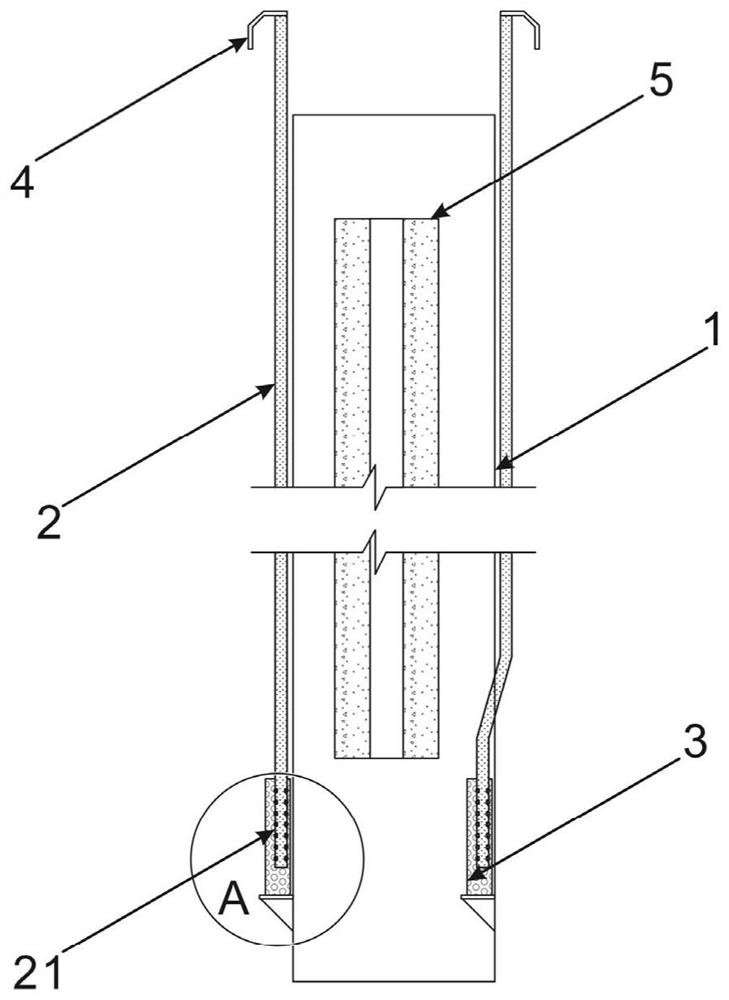

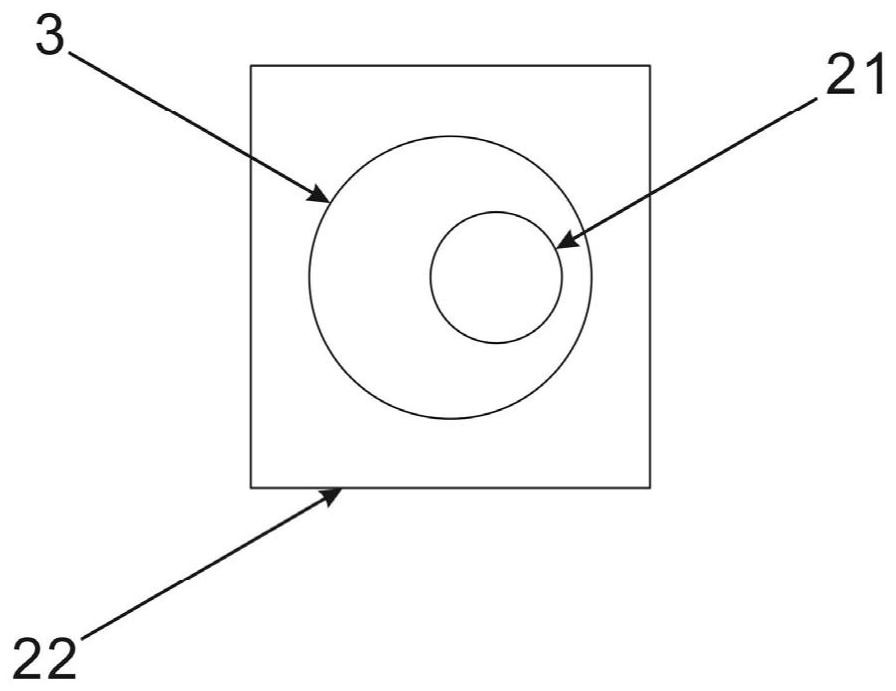

[0034] The present invention provides a combined pile structure for dealing with insufficient bearing capacity of deep foundation pit construction piles, as shown in Figure 1 and figure 2 As shown, the combined pile structure includes a steel pipe pile 1, a grouting pipe 2 and a steel pipe sleeve 3, and both sides of the steel pipe pile 1 are connected with a grouting pipe 2; the bottom section of the grouting pipe 2 is set For the pressure drop nozzle 21, the steel pipe sleeve 3 is set on the outside of the pressure drop nozzle 21, the bottom of the steel pipe sleeve 3 is blocked, and the accommodation chamber 31 is formed between the steel pipe sleeve 3 and the pressure drop nozzle 21.

[0035] Taking the construction pile 5 as a PHC pipe pile as an example, in the process of use, first draw the location of the construction pile 5 with insufficient bearing capacity on site, determine the driving depth of the steel pipe pile 1 through checking calculations, and then install t...

Embodiment 2

[0037] Embodiment 2 builds on the basis of embodiment 1:

[0038] Such as Figure 4 As shown, the grouting pipe 2 is provided with a plurality of overflow holes 211 at the bottom 20-30cm section to form a pressure drop nozzle 21; the overflow holes 211 are set as plum blossoms; Valve 212, one-way valve 212 controls the one-way flow of slurry.

[0039] Optionally, the one-way valve 212 can be made of rubber or other elastic materials.

[0040] As an optional implementation, such as Figure 4 As shown, there is a gap between the bottom of the pressure drop nozzle 21 and the bottom of the steel pipe sleeve 3, and the outer wall of the pressure drop nozzle 21 and the inner wall of the steel pipe sleeve 3 form an accommodating cavity 31, which is filled with styrofoam.

[0041]The use of a new type of pressure drop nozzle 21 combined with a steel pipe sleeve 3 filled with styrofoam can effectively solve the technical problem of the grouting pipe 2 blocking the overflow hole 211 ...

Embodiment 3

[0048] Embodiment 3 builds on the basis of embodiment 2:

[0049] Taking construction pile 5 as an example of PHC pipe pile, the construction method of using combined pile structure to deal with insufficient bearing capacity of deep foundation pit construction piles at least includes the following steps:

[0050] Step 1: Determine the location where the PHC pipe pile needs to be processed, locate and mark the coordinates in the CAD drawing, use BIM modeling, simulate the construction process of the steel pipe pile 1 being inserted into the PHC pipe pile, and check the implementation feasibility of the steel pipe pile 1 , determine the coordinates of steel pipe pile 1 to be driven;

[0051] Step 2: Engineering geological drilling data, hydrological data and piling data should be mastered before pile sinking. Ground and underground obstacles must be dealt with, and the site should be leveled, and the ground bearing capacity required for crawler crane walking should be met. Exca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com